GN Solids Control, a leading manufacturer of solids control equipment, offers a comprehensive range of products tailored to meet the specific needs of Africa's drilling industry. Among its esteemed offerings are the GN desander and desilter, which occupy a pivotal role in treating drilling fluids.

The GN desander and desilter, classified as second and third-class solid control equipment, are designed to efficiently process drilling fluids. Their classification is primarily based on the size of the cone diameter. Typically, desanders feature a cone diameter exceeding 6″, while desilters have a cone diameter less than 6″. Commonly used models, such as the 8″ and 10″ cones desander, are effective in separating solid-phase particles ranging from 47-76μm in drilling fluids. Similarly, the 5″ and 4″ cones excel in separating particles sized 15-47μm.

The GN desander and desilter, classified as second and third-class solid control equipment, are designed to efficiently process drilling fluids. Their classification is primarily based on the size of the cone diameter. Typically, desanders feature a cone diameter exceeding 6″, while desilters have a cone diameter less than 6″. Commonly used models, such as the 8″ and 10″ cones desander, are effective in separating solid-phase particles ranging from 47-76μm in drilling fluids. Similarly, the 5″ and 4″ cones excel in separating particles sized 15-47μm.

Complementing this solid-phase separation system is the JBQ series mud agitator. This agitator, especially the models below 5.5 kW, employs a blender cycloid speed reducer, making it suitable for drug liquids mixing tanks. Its compact structure ensures minimal space occupation. On the other hand, agitators rated above 7.5 kW utilize a turbo and worm gear speed reducer, offering high torque transmission, stable revolution, and reliable performance. Common models include the JBQ5.5kW, JBQ7.5kW, JBQ11kW, and JBQ15kW. These agitators are crucial components in GN Solids Control's drilling fluids processing system.

Complementing this solid-phase separation system is the JBQ series mud agitator. This agitator, especially the models below 5.5 kW, employs a blender cycloid speed reducer, making it suitable for drug liquids mixing tanks. Its compact structure ensures minimal space occupation. On the other hand, agitators rated above 7.5 kW utilize a turbo and worm gear speed reducer, offering high torque transmission, stable revolution, and reliable performance. Common models include the JBQ5.5kW, JBQ7.5kW, JBQ11kW, and JBQ15kW. These agitators are crucial components in GN Solids Control's drilling fluids processing system.

Moreover, the GNSB Series centrifugal pump plays a vital role in slurry, mud, or water transfer. It can serve as a feeding pump for desander and desilter or as a mixing pump for Jet Mud Mixer. Additionally, it finds application as a trip pump and supercharging pump for rig mud pumps. All GN model centrifugal pumps feature tungsten carbide mechanical seals and renowned brand bearings, ensuring durability and reliability. Their interchangeable spare parts with most international brand pumps facilitate easy sourcing and maintenance. The pumps' open impeller design reduces axial thrust loads, simplifying installation, repair, and maintenance processes.

Moreover, the GNSB Series centrifugal pump plays a vital role in slurry, mud, or water transfer. It can serve as a feeding pump for desander and desilter or as a mixing pump for Jet Mud Mixer. Additionally, it finds application as a trip pump and supercharging pump for rig mud pumps. All GN model centrifugal pumps feature tungsten carbide mechanical seals and renowned brand bearings, ensuring durability and reliability. Their interchangeable spare parts with most international brand pumps facilitate easy sourcing and maintenance. The pumps' open impeller design reduces axial thrust loads, simplifying installation, repair, and maintenance processes.

GN Solids Control Equipment, with its innovative designs and robust performance, is a trusted choice for Africa's drilling clients. Its desander, desilter, mud agitator, and centrifugal pump offer a comprehensive solution for efficient drilling fluid treatment, ensuring smoother and more cost-effective drilling operations.

- Details

-

Published: 11 April 2024

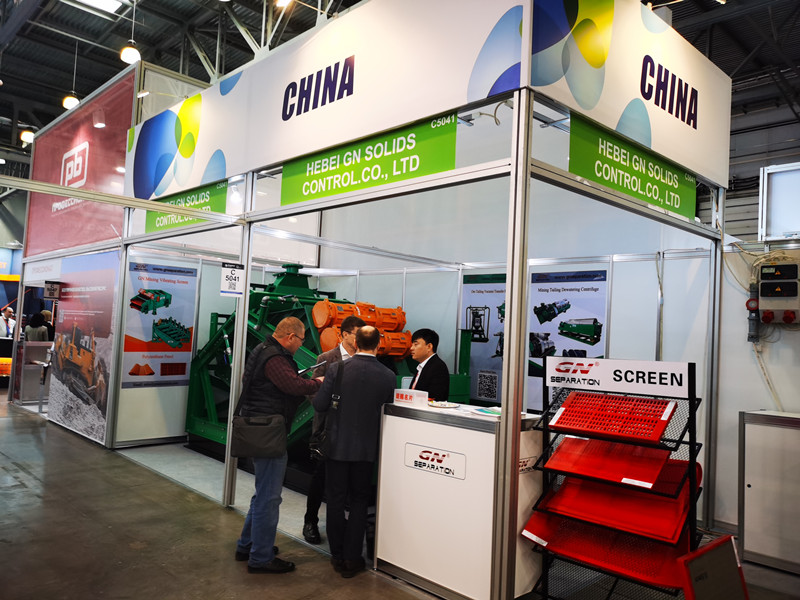

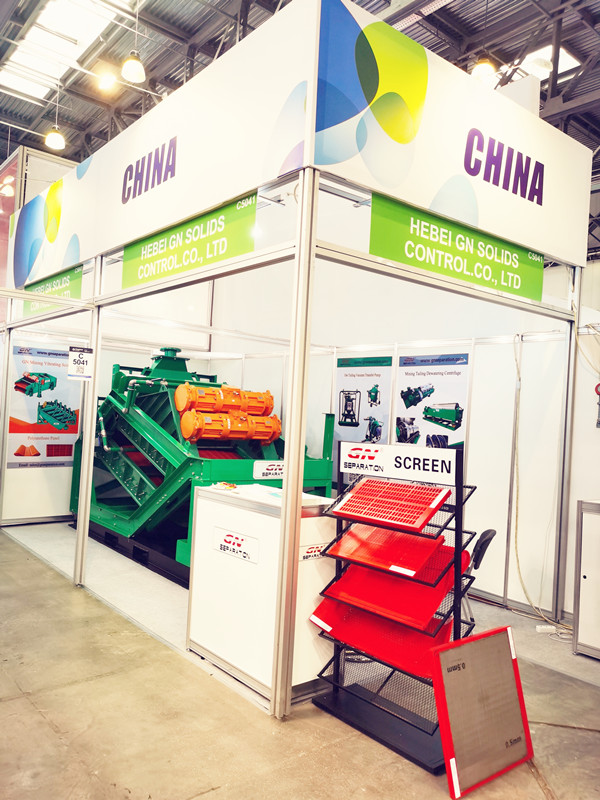

GN Separation, a leading manufacturer specializing in mineral processing equipment, is thrilled to announce its participation in the prestigious MiningWorld Russia 2024 exhibition. This year's edition, scheduled to take place from April 23 to 25, will be held at the Crocus Expo, Pavilion 1, in Moscow, Russia.

At the heart of GN Separation's showcase will be its cutting-edge GN Stack Vibrating Screen. This remarkable piece of machinery is primarily designed for wet screening, classification, and dehydration of fine-grained materials across various industries, including mineral processing and coal preparation. Its versatility and adaptability make it a standout choice for on-site operations, as it can be configured with 2 to 5 layers depending on specific requirements.

At the heart of GN Separation's showcase will be its cutting-edge GN Stack Vibrating Screen. This remarkable piece of machinery is primarily designed for wet screening, classification, and dehydration of fine-grained materials across various industries, including mineral processing and coal preparation. Its versatility and adaptability make it a standout choice for on-site operations, as it can be configured with 2 to 5 layers depending on specific requirements.

The GN Stack Vibrating Screen is a testament to GN's innovative spirit and technological prowess. Driven by a single vibration source, comprising dual vibration motors, it utilizes the principle of two-degree-of-freedom resonance to achieve linear vibration throughout the entire machine. This unique vibration mode not only ensures energy efficiency but also delivers exceptional screening efficiency and processing capacity.

The GN Stack Vibrating Screen is a testament to GN's innovative spirit and technological prowess. Driven by a single vibration source, comprising dual vibration motors, it utilizes the principle of two-degree-of-freedom resonance to achieve linear vibration throughout the entire machine. This unique vibration mode not only ensures energy efficiency but also delivers exceptional screening efficiency and processing capacity.

What sets the GN Stack Vibrating Screen apart is its advanced technology, simple yet robust design, and reliable operation. Its Polyurethane Screen Mesh boasts a high opening rate ranging from 28-45%, ensuring optimal performance and extending the mesh's lifespan to over six months. These features collectively position the GN Stack Vibrating Screen as one of the most advanced equipment in fine-grained material screening.

What sets the GN Stack Vibrating Screen apart is its advanced technology, simple yet robust design, and reliable operation. Its Polyurethane Screen Mesh boasts a high opening rate ranging from 28-45%, ensuring optimal performance and extending the mesh's lifespan to over six months. These features collectively position the GN Stack Vibrating Screen as one of the most advanced equipment in fine-grained material screening.

At MiningWorld Russia 2024, GN Separation invites visitors to booth B5001, Hall 2, to witness the GN Stack Vibrating Screen in action and discover how it can revolutionize their mineral processing operations. With its unparalleled performance and reliability, GN Separation is confident that its solutions will meet and exceed the expectations of mining professionals from around the globe.

For more information about GN Separation and its products, please visit our official website or contact us directly at the exhibition. We look forward to meeting you at MiningWorld Russia 2024 and discussing how we can collaborate to achieve greater efficiencies and success in the mining industry.

- Details

-

Published: 02 April 2024

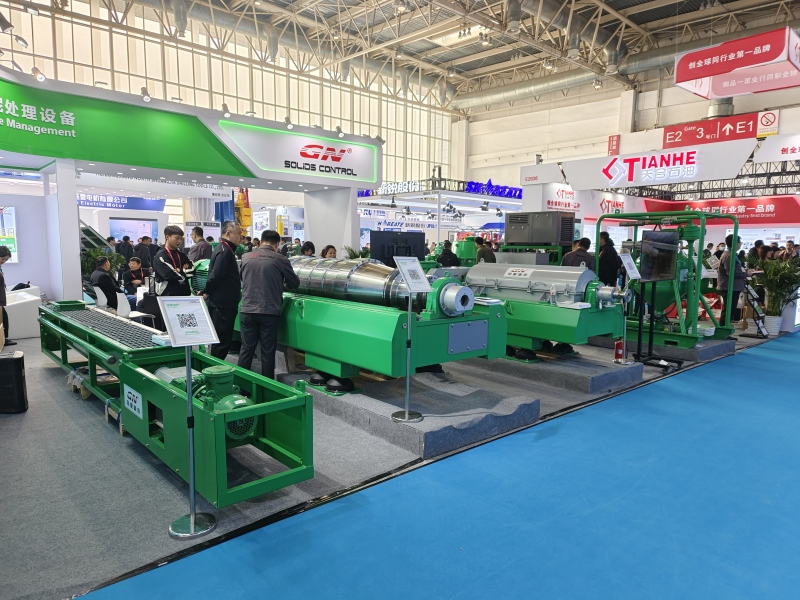

This week, GN Solids Control proudly participated in the 24th China International Petroleum & Petrochemical Technology and Equipment Exhibition, commonly known as the Beijing CIPPE Oil Equipment Show, held at the Beijing New China International Exhibition Center.

The event provided a platform for GN to showcase its latest equipment and technological advancements in the oil and gas industry.

The event provided a platform for GN to showcase its latest equipment and technological advancements in the oil and gas industry.

Among the highlights of the exhibition was the GN ViST Shaker, a traditional shaker enhanced with a vacuum screen unit. This innovative equipment is capable of recovering an impressive 20~30% of liquid from drilling mud, significantly reducing waste and minimizing the need for new drilling mud over time.

Among the highlights of the exhibition was the GN ViST Shaker, a traditional shaker enhanced with a vacuum screen unit. This innovative equipment is capable of recovering an impressive 20~30% of liquid from drilling mud, significantly reducing waste and minimizing the need for new drilling mud over time.

Furthermore, GN Solids Control exhibited its Decanter Centrifuge, a core unit for solids and liquid separation. The displayed models included the 2-phase decanter centrifuge GNLW632A and GNLW554FT-VFD, as well as the advanced Second Generation 3-phase decanter centrifuge GNLWS364FT-VFD. These centrifuges are designed to efficiently separate solids from liquids, ensuring optimal performance in various oilfield applications.

Furthermore, GN Solids Control exhibited its Decanter Centrifuge, a core unit for solids and liquid separation. The displayed models included the 2-phase decanter centrifuge GNLW632A and GNLW554FT-VFD, as well as the advanced Second Generation 3-phase decanter centrifuge GNLWS364FT-VFD. These centrifuges are designed to efficiently separate solids from liquids, ensuring optimal performance in various oilfield applications.

GN also showcased its disc stack separator, a device that utilizes high-speed centrifugal force to rapidly separate solid and liquid. The exhibited 3-phase disc stack separator GNSD90 demonstrated GN's commitment to providing cutting-edge technology in the field of solids control.

GN also showcased its disc stack separator, a device that utilizes high-speed centrifugal force to rapidly separate solid and liquid. The exhibited 3-phase disc stack separator GNSD90 demonstrated GN's commitment to providing cutting-edge technology in the field of solids control.

Additionally, the GN Cuttings Dryer, widely used in OBM and SBM treating, was a key attraction at the exhibition. This dryer effectively controls the oil content in cuttings to below 5%, significantly reducing it from levels above 15%. GN Solids Control offers cuttings dryers with interchangeable screen baskets of different sizes, tailored to meet the specific needs of various materials.

Additionally, the GN Cuttings Dryer, widely used in OBM and SBM treating, was a key attraction at the exhibition. This dryer effectively controls the oil content in cuttings to below 5%, significantly reducing it from levels above 15%. GN Solids Control offers cuttings dryers with interchangeable screen baskets of different sizes, tailored to meet the specific needs of various materials.

The GN Solids Vacuum Pump was another star attraction at the show. Models GNSP-10B and GNSP-40B were displayed, offering a reliable solution for moving high-viscosity drilling cuttings, solids, or sludge. GN has developed three distinct models of vacuum pumps, including GNSP-10B, GNSP-20B, and GNSP-40B, each designed to meet specific challenges in the oilfield.

Lastly, the GN Screw Conveyor, an efficient solids transfer unit, was also exhibited. It is commonly used to remove drill cuttings discharged from shakers, desanders, and desilters, ensuring smooth and efficient operation within a certain length.

GN Solids Control, as a leading provider of solids control equipment and solutions, has established a strong reputation in the global oil and gas industry. With a focus on innovation and quality, the company continuously invests in research and development to bring the most advanced technology to its customers. GN's products are widely recognized for their reliability, durability, and efficiency, making them a trusted choice for oilfield operations worldwide.

The company's participation in the Beijing CIPPE Oil Equipment Show further demonstrates its commitment to staying at the forefront of the industry and sharing its expertise with a global audience. GN Solids Control looks forward to continuing to serve its customers with innovative and reliable equipment that supports sustainable and efficient oilfield operations.

- Details

-

Published: 29 March 2024

GN's innovative 2nd generation Three-Phase Decanter Centrifuge is poised to take center stage at the highly anticipated 2024 CIPPE Exhibition in Beijing. This advanced machinery is a testament to GN Solids Control's commitment to excellence in solids control technology.

The GN Three-phase decanter centrifuge revolutionizes the process of separating two liquid phases from a solid phase, all within a single operation. The fundamental principle of this decanter centrifuge lies in the powerful G force, which enables the efficient segregation of immiscible liquids and solids based on their varying densities. This remarkable technology allows for the concurrent discharge of all three phases, thus greatly enhancing the efficiency of the separation process.

GN Solids Control, a leading manufacturer in the field, specializes in designing and crafting three-phase decanters in a range of bowl sizes, including 360mm, 450mm, and 550mm. However, it is worth noting that for effective 3-phase separation, the solid phase must possess the highest density, while the two liquid phases must exhibit distinct density differences.

GN Solids Control, a leading manufacturer in the field, specializes in designing and crafting three-phase decanters in a range of bowl sizes, including 360mm, 450mm, and 550mm. However, it is worth noting that for effective 3-phase separation, the solid phase must possess the highest density, while the two liquid phases must exhibit distinct density differences.

Structurally and functionally, the three-phase decanter centrifuge mirrors the two-phase model, with a key distinction in the manner of liquid discharge. In a 3-phase decanter centrifuge, the higher-density liquid phase is expelled under pressure, whereas the lower-density liquid is discharged without the application of pressure. This intricate yet efficient design ensures precise and controlled separation.

GN Solids Control, a renowned player in the global solids control industry, is renowned for its commitment to innovation and quality. The company's expertise in centrifuge technology is unmatched, and its products are widely recognized for their reliability and durability. GN Solids Control's participation in the 2024 CIPPE Exhibition is a testament to its leadership position in the industry and a demonstration of its dedication to advancing solids control solutions worldwide.

The upcoming exhibition in Beijing presents a unique opportunity for industry professionals to witness the capabilities of GN's 2nd generation Three-Phase Decanter Centrifuge and appreciate the intricate engineering that lies behind it. GN Solids Control looks forward to sharing its innovations and expertise with visitors from around the globe.

- Details

-

Published: 22 March 2024

GN Solids Control, a renowned company in the field of oilfield services, prides itself on providing cutting-edge equipment for drilling fluid processing. Among its comprehensive range of products, the JBQ series mud agitators and ZCQ series vacuum degassers stand out as vital components in ensuring smooth and efficient drilling operations.

The JBQ series mud agitators are designed to cater to various drilling needs. The agitators with less than 5.5 kW power rating utilize a blender cycloid speed reducer, making them suitable for drug liquids mixing tanks. Their compact structure ensures minimal space occupation, making them an ideal choice for tight workspaces. On the other hand, agitators with over 7.5 kW power rating employ a turbo and worm gear speed reducer, delivering high torque transmission and stable revolution. These agitators work reliably, exhibiting exceptional performance in diverse drilling conditions. Common models such as JBQ5.5kW, JBQ7.5kW, JBQ11kW, and JBQ15kW cater to a wide range of applications.

The JBQ series mud agitators are designed to cater to various drilling needs. The agitators with less than 5.5 kW power rating utilize a blender cycloid speed reducer, making them suitable for drug liquids mixing tanks. Their compact structure ensures minimal space occupation, making them an ideal choice for tight workspaces. On the other hand, agitators with over 7.5 kW power rating employ a turbo and worm gear speed reducer, delivering high torque transmission and stable revolution. These agitators work reliably, exhibiting exceptional performance in diverse drilling conditions. Common models such as JBQ5.5kW, JBQ7.5kW, JBQ11kW, and JBQ15kW cater to a wide range of applications.

The drilling mud agitator is a crucial element in the GN Solids Control drilling fluids processing system. It ensures the homogeneity of the drilling mud, vital for maintaining drilling efficiency and safety.

The ZCQ series vacuum degasser, a specialized device designed to efficiently remove gases from drilling fluids. Its ability to quickly eliminate invasive gases is crucial for maintaining mud gravity, stabilizing mud viscosity, and ultimately reducing drilling costs. Moreover, the vacuum degasser doubles as a heavy-duty agitator, compatible with all types of mud circulation purification systems. The scientific and rational design of the vacuum degasser ensures effective gas-liquid separation, filtering out impurities and keeping the exhaust pipe unobstructed.

The ZCQ series vacuum degasser, a specialized device designed to efficiently remove gases from drilling fluids. Its ability to quickly eliminate invasive gases is crucial for maintaining mud gravity, stabilizing mud viscosity, and ultimately reducing drilling costs. Moreover, the vacuum degasser doubles as a heavy-duty agitator, compatible with all types of mud circulation purification systems. The scientific and rational design of the vacuum degasser ensures effective gas-liquid separation, filtering out impurities and keeping the exhaust pipe unobstructed.

GN Solids Control, with its roots in China, has emerged as a global leader in solids control technology. The company's commitment to innovation and quality has made it a trusted partner in the oil and gas industry. Its products, including the mud agitators and vacuum degassers, are designed to meet the most stringent standards, ensuring optimal performance in even the most challenging drilling conditions. GN Solids Control's expertise and dedication to excellence have positioned it at the forefront of the oilfield service industry, setting new benchmarks for performance and reliability.

- Details

-

Published: 14 March 2024