GN Solids Control Co., Ltd., a leading manufacturer of centrifugal pumps and solids control equipment, is delighted to announce its partnership with a Bolivia-based customer. This esteemed client has placed their trust in GN Solids Control's high-quality products, accumulating over 10 of our centrifuges over the years.

The screw pump, decanter centrifuge, and shale shaker are the cornerstones of their drilling operations. The screw pump effectively pumps drilling mud, ensuring a continuous flow. The decanter centrifuge's advanced design separates solids from the mud, maintaining fluid clarity and optimizing drilling efficiency. The shale shaker screens out drill cuttings, further enhancing solids control and enabling safer and more environmentally friendly drilling practices.

GN Solids Control's products are known for durability, efficiency, and reliable performance. Our commitment to innovation and customer satisfaction has made us a trusted partner in the Bolivia drilling industry. We look forward to continuing our successful partnership with this Bolivia-based customer and expanding our reach to other drilling operators seeking top-tier centrifuge solutions.

GN Solids Control's centrifugal pumps and solids control centrifuges have been designed to meet the specific challenges of Bolivia's drilling operations. Whether it's the unique properties of Bolivian drilling mud or the high altitudes encountered in some drilling sites, our equipment is tailored to perform under the most demanding conditions.

Our decanter centrifuge, for instance, is renowned for its robustness and efficient solids separation capabilities. It handles large volumes of drilling mud while maintaining excellent clarity, crucial for ensuring safe and efficient drilling operations.

The shale shaker, on the other hand, is specifically designed to handle Bolivia's unique drilling challenges, screening out drill cuttings effectively while minimizing wear and tear on the equipment.

Our partnership with Bolivia's drilling operators is built on a foundation of trust and mutual success. We pride ourselves on our commitment to providing top-tier customer service, ensuring that our clients receive the support they need to keep their operations running smoothly. Whether it's providing quick repairs or offering advice on improving drilling efficiency, we are always available to help.

With a focus on innovation and continuous improvement, GN Solids Control remains at the forefront of centrifuge technology. We are excited about the future of our partnership with Bolivia's drilling industry and look forward to playing a key role in its continued growth and success.

- Details

-

Published: 19 January 2024

GN Solids Control, a leading manufacturer of solid control equipment, is proud to announce the delivery of two high-capacity mud dewatering centrifuge units to a client in South America. These advanced systems, featuring the GNLW654 decanter centrifuge and a polymer dosing system, are specifically designed for the treatment of tailings sludge with high solid concentrations. By employing chemical agents to aggregate fine particles into larger solids, the centrifuge efficiently separates the solid phase, purifying the liquid phase.

GNLW654 Decanter Centrifuge: This powerful centrifuge is carefully engineered to handle the high solid content of tailings sludge. It incorporates a large drum capable of accommodating a substantial amount of material for processing.

Polymer Dosing System: To enhance the separation process, a polymer dosing system is utilized. Chemical additives are precisely mixed with the sludge to promote the formation of larger solid particles. This enhances the separation efficiency of the centrifuge, allowing for a more effective dewatering process.

Efficient Solid-Liquid Separation: The high-speed rotation of the decanter centrifuge, combined with the use of chemical additives, facilitates the efficient separation of solid and liquid phases. This results in a significant reduction in the moisture content of the sludge, making it easier to handle and dispose of.

Enhanced Environmental Compliance: By effectively separating the solid phase from the liquid phase, the centrifuge units help to reduce the environmental impact of tailings disposal. The purified liquid phase can be reused, minimizing freshwater consumption and potential pollution.

Increased Productivity: The high capacity of the GNLW654 decanter centrifuge allows for a continuous and uninterrupted dewatering process. This increases productivity and reduces downtime for maintenance and cleaning.

The delivery of two big bowl mud dewatering centrifuge units to South America marks another milestone in GN Solids Control's commitment to providing innovative and efficient solutions for the treatment of tailings sludge. By incorporating advanced technologies such as the GNLW654 decanter centrifuge and a polymer dosing system, GN Solids Control continues to be at the forefront of the industry, offering reliable and sustainable solutions for solid-liquid separation.

- Details

-

Published: 05 January 2024

In this project, GN delivered the GNLW-364 decanter centrifuge, its VFD electric control cabinet, and a polymer dosing unit. In the chemical industry, users often need to separate small particles of solids, so a flocculant needs to be added to bind the small particles of solids into larger ones, and then pumped into the centrifuge for solid-liquid separation. The GNLW364 model has a longer rotor, which allows the material to stay in the rotor for a longer time, resulting in more thorough solid-liquid separation. This allows the customer to obtain a drier solid phase and a cleaner liquid phase.

GN Solids Control has extensive experience and expertise in the field of centrifuge separation technology. Their products are known for their high efficiency, reliability, and durability. In addition, they offer excellent customer service and technical support to ensure that customers' needs are met.

Overall, the GNLW364-VFD Decanter Centrifuge is an ideal solution for overseas chemical plants that require efficient solid-liquid separation. With its advanced technology and reliable performance, this centrifuge can help plants improve production efficiency and product quality. Till now, GN decanter centrifuge already was exported to more than 70 countries and served more than 100000 project. Especially the oil gas industry and drilling industry. We have one series centrifuge with different treating capacity and application. For dewatering , clarification ,separation. GN will recommend model according to your project. Customized separation system is also what we are good at. From GN website you can find, we have shaker,hydrocyclone ,decanter centrifuge ,screw press dewatering machine for different kind material and different sizes solids separation. We provide customized separate solution for your project to help you save cost and improve working efficiency.

In addition, GN Solids America was established to better serve local customers. With their local presence and expertise, GN Solids America can provide more personalized and timely support to meet the specific needs of customers in the Americas region.

- Details

-

Published: 29 December 2023

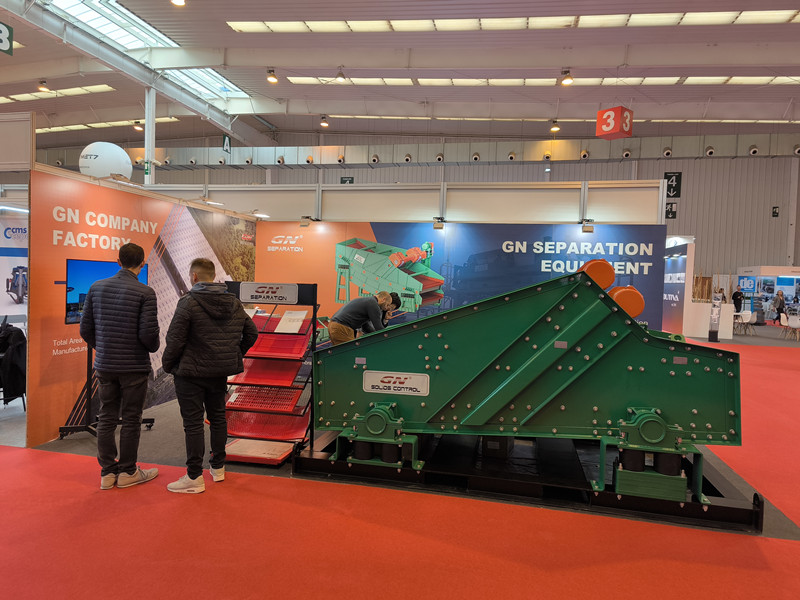

GN Separation, a leading manufacturer of solid-liquid separation equipment, recently took part in the SMOPYC Mining Exhibition, one of the most prestigious mining events in Spain. The exhibition saw a wide range of companies displaying their latest products and technologies, and GN Separation was no exception. The company showcased its top-of-the-line solid-liquid separation solutions, including the Linear Vibrating Screen GNLMP1224 and polyurethane screen panels.

The Linear Vibrating Screen GNLMP1224 is designed for the efficient separation of solid particles from liquids, making it an ideal choice for the mining industry. Its high-performance capabilities and durability make it an excellent solution for the rigorous demands of mining operations. The polyurethane screen panels, on the other hand, are known for their long service life and high screening efficiency, making them a popular choice for many mining applications.

Aside from mining screens, GN Separation is also known for providing customized solid-liquid separation solutions to its customers. Depending on the size of solid particles, GN offers a range of separation equipment such as hydrocyclones, decanter centrifuges, disc stack separators, and more. These solutions are tailored to the specific requirements of customers, ensuring that their separation needs are met effectively.

GN Separation also excels in combining different separation equipment to create a comprehensive system that meets the unique needs of its customers. By integrating various separation equipment and process systems, GN is able to provide efficient and cost-effective solutions for a wide range of applications.

At the SMOPYC Mining Exhibition, GN Separation had the opportunity to showcase its expertise and innovative solutions in the field of solid-liquid separation. The company's participation in the exhibition was a great success, allowing it to connect with industry professionals and showcase its commitment to delivering high-quality products and services to the mining sector.

Overall, GN Separation's presence at the SMOPYC Mining Exhibition demonstrated its dedication to providing advanced solid-liquid separation solutions for the mining industry. With its extensive range of products and customized solutions, the company continues to play a significant role in meeting the evolving needs of the mining sector.

- Details

-

Published: 24 November 2023

When it comes to drilling operations, the need for efficient and reliable solids control equipment and pumps is essential. Asia Drilling Company, a leading player in the oil and gas industry, understands the importance of using high-quality equipment to ensure smooth and effective drilling operations. This is why they have turned to GN Solids Control, a factory with 15 years of experience in the production of separation and conveying equipment.

GN Solids Control is well-known for its expertise in providing one-stop solutions for solid-liquid separation and conveying problems. The company offers a range of solid control equipment and pumps, including the GN centrifugal pump and the 20B vacuum pump, both of which are vital for the success of drilling operations.

The GN centrifugal pump is designed to handle drilling fluids and is widely used for a variety of applications, including transferring mud to shakers, desanders, and desilters. It is a highly efficient and reliable pump that helps to maintain the proper pressure and flow of drilling fluids, ensuring the smooth running of the entire drilling process.

The GN centrifugal pump is designed to handle drilling fluids and is widely used for a variety of applications, including transferring mud to shakers, desanders, and desilters. It is a highly efficient and reliable pump that helps to maintain the proper pressure and flow of drilling fluids, ensuring the smooth running of the entire drilling process.

In addition to the centrifugal pump, GN Solids Control also offers the 20B vacuum pump, which is used for the safe and efficient transfer of drilling fluids. This pump is designed to handle a wide range of fluids, including corrosive and abrasive materials, making it a versatile and reliable solution for Asia Drilling Company's operations.

What sets GN Solids Control apart is its commitment to providing customized equipment systems to meet the specific needs of its clients. With a strong focus on technical support and a wealth of manufacturing experience, GN Solids Control is able to design and deliver equipment systems that are not only efficient and reliable but also tailored to the unique requirements of Asia Drilling Company.

In conclusion, the partnership between GN Solids Control and Asia Drilling Company is a testament to the importance of using high-quality solids control equipment and pumps in the drilling industry. With GN Solids Control's expertise and commitment to excellence, Asia Drilling Company can be confident in the reliability and efficiency of its equipment, ensuring the success of its drilling operations.

- Details

-

Published: 17 November 2023