On 13th May, GN will proudly exhibit at IFAT MUNICH 2024, a globally renowned trade fair for environmental technology, water, and wastewater management. Held from May 13 to 17, 2024, at the New International Exhibition Center, Messe München GmbH, in Munich, Germany, IFAT MUNICH is a must-attend event for industry professionals worldwide.

At Hall No. A1, Booth 104-B, GN will showcase its latest innovations, including the 9-inch Decanter Centrifuge. This mini centrifuge, with a bowl diameter of 9 inches (220mm), is designed for industrial applications where space is limited or capacity requirements are small. Its compact design makes it a popular choice for solids-liquid separation in various applications. Moreover, it is considered the perfect tool for experimental testing with decanter centrifuges. GN offers this centrifuge in three configurations: fixed gearbox drive, fully hydraulic drive, and variable frequency drive, ensuring flexibility and adaptability to different operational needs.

At Hall No. A1, Booth 104-B, GN will showcase its latest innovations, including the 9-inch Decanter Centrifuge. This mini centrifuge, with a bowl diameter of 9 inches (220mm), is designed for industrial applications where space is limited or capacity requirements are small. Its compact design makes it a popular choice for solids-liquid separation in various applications. Moreover, it is considered the perfect tool for experimental testing with decanter centrifuges. GN offers this centrifuge in three configurations: fixed gearbox drive, fully hydraulic drive, and variable frequency drive, ensuring flexibility and adaptability to different operational needs.

Additionally, GN will display its Sludge Vacuum Pump, also known as a solids transfer pump. This pneumatic slurry transfer vacuum pump is ideal for transferring liquids, slurries, and solids. With its high vacuum loading capacity, it can handle tough environments for solids or sludge transfer, offering superior performance and minimal maintenance. The pump is capable of handling materials with high gravity and density, including dry solids or slurries with solids content up to 80%.

Additionally, GN will display its Sludge Vacuum Pump, also known as a solids transfer pump. This pneumatic slurry transfer vacuum pump is ideal for transferring liquids, slurries, and solids. With its high vacuum loading capacity, it can handle tough environments for solids or sludge transfer, offering superior performance and minimal maintenance. The pump is capable of handling materials with high gravity and density, including dry solids or slurries with solids content up to 80%.

At IFAT MUNICH 2024, GN aims to demonstrate its commitment to providing cutting-edge solutions in environmental technology and wastewater management. We invite you to visit our booth to learn more about our products and services. We look forward to meeting you and discussing how GN can contribute to your environmental initiatives.

Hebei GN Solids Control Co., Ltd. has established itself as a leading manufacturer of solids control and waste management equipment, with over 15 years of expertise in the field. GN stands tall among the global giants in solids control equipment manufacturing. Operating from three factories spanning a total area of 110,000 square meters in China, we also maintain branch offices with service capabilities in the United States and Australia.

Hebei GN Solids Control Co., Ltd. has established itself as a leading manufacturer of solids control and waste management equipment, with over 15 years of expertise in the field. GN stands tall among the global giants in solids control equipment manufacturing. Operating from three factories spanning a total area of 110,000 square meters in China, we also maintain branch offices with service capabilities in the United States and Australia.

Recognized as a National High-Tech Enterprise, GN prides itself on its robust management system. Since 2010, we have proudly upheld the American API Quality Management System Certification for 14 consecutive years and have maintained certifications from the China Classification Society for ISO9001, ISO14001, and ISO45001 over several years. Additionally, our solids control equipment is certified by EU CE, ATEX, and International IECEx.

To ensure seamless production and operation, GN employs an ERP Cloud + CRM Cloud management system, guaranteeing digital control over the production process and quality traceability. Our products are highly sought after internationally, with approximately 70% being exported to over 70 countries worldwide. GN remains committed to providing exceptional solids control and waste management solutions to the global market.

- Details

-

Published: 10 May 2024

GN Solids America, a branch of GN Solids Control, is excited to announce its participation in the 2024 Offshore Technology Conference (OTC) from May 6 to May 9, 2024. The event, held annually in Houston, Texas, USA, brings together the brightest minds in the offshore oil and gas industry to discuss innovations and advancements.

At NRG Center, booth 1926, GN Solids America will showcase a range of products designed to improve solids control and fluid recovery during drilling operations. The exhibition lineup includes:

ViST Vacuum Shale Shaker: This innovative shale shaker offers wide applicability for Oil-Based Mud (OBM), Synthetic-Based Mud (SBM), and Water-Based Mud (WBM). It reduces waste and recovers fluids effectively in both onshore and offshore environments. One of its key advantages is the ability to replace high-G drying shale shakers without additional screen consumption. The ViST Vacuum Shale Shaker boasts a compact design, easy installation without welding, and adjustable suction and discharge times to suit different drilling conditions. It can be connected to 2-3 shakers with a single air supply, making it a highly versatile and cost-effective solution.

ViST Vacuum Shale Shaker: This innovative shale shaker offers wide applicability for Oil-Based Mud (OBM), Synthetic-Based Mud (SBM), and Water-Based Mud (WBM). It reduces waste and recovers fluids effectively in both onshore and offshore environments. One of its key advantages is the ability to replace high-G drying shale shakers without additional screen consumption. The ViST Vacuum Shale Shaker boasts a compact design, easy installation without welding, and adjustable suction and discharge times to suit different drilling conditions. It can be connected to 2-3 shakers with a single air supply, making it a highly versatile and cost-effective solution.

Decanter Centrifuge: GN Solids America designs and manufactures decanter centrifuges and three-phase centrifuges tailored to specific separation tasks. Using resilient, high-quality materials, GN centrifuges offer superior performance. Additionally, GN's expertise in designing PLC and electrical control systems gives it a competitive edge in measuring and control technology.

Decanter Centrifuge: GN Solids America designs and manufactures decanter centrifuges and three-phase centrifuges tailored to specific separation tasks. Using resilient, high-quality materials, GN centrifuges offer superior performance. Additionally, GN's expertise in designing PLC and electrical control systems gives it a competitive edge in measuring and control technology.

Sludge Vacuum Pump: Also known as a solids transfer pump, this pneumatic slurry transfer vacuum pump is ideal for liquid, slurry, and solids transfer. Its efficient design ensures smooth and reliable operation.

Shaker Screens: GN's automated production line for shale shaker screens utilizes CNC punching machines, robot welding, and injection molding machines to produce high-quality screens with consistent performance. GN Solids Control's global network of branches and partners ensures technical support, consignment support, and fast delivery to the international drilling industry.

Visit GN Solids America at booth 1926 at the 2024 Offshore Technology Conference in Houston, Texas, to learn more about these products and how they can enhance your drilling operations. We look forward to meeting you there!

Visit GN Solids America at booth 1926 at the 2024 Offshore Technology Conference in Houston, Texas, to learn more about these products and how they can enhance your drilling operations. We look forward to meeting you there!

- Details

-

Published: 30 April 2024

GN Solids Control, a leading manufacturer of solids control equipment, offers a comprehensive range of products tailored to meet the specific needs of the drilling industry. We are proud to announce another order delivery for the domestic market.

The GN Desander and Desilter Centrifuge is a highly efficient solid-liquid separation equipment that is primarily utilized for removing solid particles such as sand and mud from drilling fluids. This specialized piece of machinery, a large rotating drum centrifuge, is designed to excel in its function.

The GN Desander and Desilter Centrifuge is a highly efficient solid-liquid separation equipment that is primarily utilized for removing solid particles such as sand and mud from drilling fluids. This specialized piece of machinery, a large rotating drum centrifuge, is designed to excel in its function.

The centrifugal force generated by the rotating drum and screw conveyor assembly within the machine effectively separates the solid particles from the drilling fluid. These solids are then expelled through designated outlets, ensuring a cleaner and more refined drilling fluid.

The centrifugal force generated by the rotating drum and screw conveyor assembly within the machine effectively separates the solid particles from the drilling fluid. These solids are then expelled through designated outlets, ensuring a cleaner and more refined drilling fluid.

One of the key advantages of the GN Desander and Desilter Centrifuge is its ability to handle a wide range of particle sizes. Its large capacity allows for efficient processing, making it suitable for various drilling applications. Additionally, its compact design and straightforward operation contribute to its ease of use and maintenance.

When compared to traditional desanding and desilting machines, the GN Centrifuge offers superior separation efficiency and a higher quality of recovered drilling fluid. This not only improves the solid-phase control of the drilling fluid but also enhances drilling efficiency, ultimately leading to reduced drilling costs.

Given its exceptional performance and reliability, the GN Desander and Desilter Centrifuge holds immense potential in the petroleum drilling industry. It is a valuable asset that can significantly contribute to improving the overall quality of drilling operations and reducing operational costs.

In conclusion, the GN Desander and Desilter Centrifuge is a cutting-edge solid-liquid separation solution for China's drilling companies. Its high separation efficiency, large capacity, and user-friendly design make it a top choice for enhancing drilling fluid quality and drilling efficiency, ultimately driving down costs and maximizing operational benefits.

- Details

-

Published: 26 April 2024

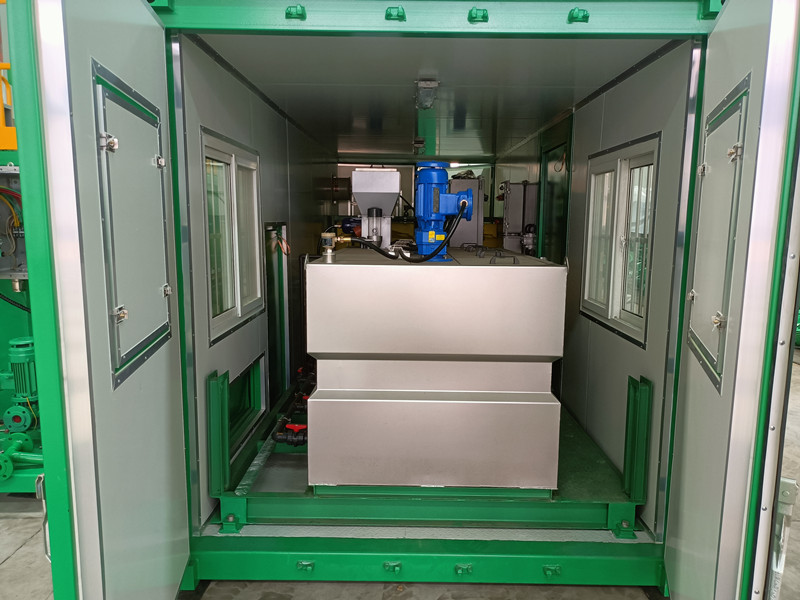

For our esteemed customer in the Middle East, we proudly present the GN 5m3 Oily Sludge Treatment System, a comprehensive solution tailored to meet the unique challenges of oily sludge treatment in the region. This advanced system is designed to efficiently and effectively treat oily sludge, ensuring environmental compliance and operational excellence.

At the heart of this system lies the Premixing tank, which serves as the initial stage of the treatment process. It is responsible for homogenizing the sludge mixture, preparing it for further processing.

The GNZS706 fine shaker, as the first phase solids control equipment in the drilling fluids processing system, plays a pivotal role in the overall solids control process. Also known as the key solids control equipment in the drilling mud system, the shale shaker determines the performance of the entire solids control system. GN Solids Control offers a range of customizable options, including double shakers and triplicate shakers on a single skid, to meet the specific requirements of our clients. Additionally, we provide relevant connecting manifolds, ensuring seamless integration within the overall system.

The GNZS706 fine shaker, as the first phase solids control equipment in the drilling fluids processing system, plays a pivotal role in the overall solids control process. Also known as the key solids control equipment in the drilling mud system, the shale shaker determines the performance of the entire solids control system. GN Solids Control offers a range of customizable options, including double shakers and triplicate shakers on a single skid, to meet the specific requirements of our clients. Additionally, we provide relevant connecting manifolds, ensuring seamless integration within the overall system.

Our GNLW364 three-phase decanter centrifuge is a technological marvel, designed to simultaneously separate two liquid phases from a solid phase. The separation principle of the decanter centrifuge relies on G force, which allows for the efficient separation of the different densities of the immiscible liquids and solid. This ensures that all three phases can be discharged simultaneously, greatly enhancing the efficiency of the entire treatment process.

Our GNLW364 three-phase decanter centrifuge is a technological marvel, designed to simultaneously separate two liquid phases from a solid phase. The separation principle of the decanter centrifuge relies on G force, which allows for the efficient separation of the different densities of the immiscible liquids and solid. This ensures that all three phases can be discharged simultaneously, greatly enhancing the efficiency of the entire treatment process.

GN Solids Control is a leader in the design and manufacture of three-phase decanters, offering a range of bowl sizes including 360mm, 450mm, and 550mm to cater to different treatment requirements. Our expertise in this field ensures that our centrifuges are not only highly efficient but also durable and reliable, providing our clients with a cost-effective and long-term solution for oily sludge treatment.

In conclusion, the GN 5m3 Oily Sludge Treatment System, with its comprehensive configuration including the Premixing tank, GNZS706 fine shaker, GNLW364 three-phase decanter centrifuge, and containerized chemical dosing system, offers a comprehensive and efficient solution for oily sludge treatment in the Middle East. We are confident that this system will meet the stringent environmental regulations and operational demands of our customer, while also contributing to the sustainable development of the region.

In conclusion, the GN 5m3 Oily Sludge Treatment System, with its comprehensive configuration including the Premixing tank, GNZS706 fine shaker, GNLW364 three-phase decanter centrifuge, and containerized chemical dosing system, offers a comprehensive and efficient solution for oily sludge treatment in the Middle East. We are confident that this system will meet the stringent environmental regulations and operational demands of our customer, while also contributing to the sustainable development of the region.

- Details

-

Published: 19 April 2024

GN Solids Control, a leading manufacturer of solids control equipment, offers a comprehensive range of products tailored to meet the specific needs of Africa's drilling industry. Among its esteemed offerings are the GN desander and desilter, which occupy a pivotal role in treating drilling fluids.

The GN desander and desilter, classified as second and third-class solid control equipment, are designed to efficiently process drilling fluids. Their classification is primarily based on the size of the cone diameter. Typically, desanders feature a cone diameter exceeding 6″, while desilters have a cone diameter less than 6″. Commonly used models, such as the 8″ and 10″ cones desander, are effective in separating solid-phase particles ranging from 47-76μm in drilling fluids. Similarly, the 5″ and 4″ cones excel in separating particles sized 15-47μm.

The GN desander and desilter, classified as second and third-class solid control equipment, are designed to efficiently process drilling fluids. Their classification is primarily based on the size of the cone diameter. Typically, desanders feature a cone diameter exceeding 6″, while desilters have a cone diameter less than 6″. Commonly used models, such as the 8″ and 10″ cones desander, are effective in separating solid-phase particles ranging from 47-76μm in drilling fluids. Similarly, the 5″ and 4″ cones excel in separating particles sized 15-47μm.

Complementing this solid-phase separation system is the JBQ series mud agitator. This agitator, especially the models below 5.5 kW, employs a blender cycloid speed reducer, making it suitable for drug liquids mixing tanks. Its compact structure ensures minimal space occupation. On the other hand, agitators rated above 7.5 kW utilize a turbo and worm gear speed reducer, offering high torque transmission, stable revolution, and reliable performance. Common models include the JBQ5.5kW, JBQ7.5kW, JBQ11kW, and JBQ15kW. These agitators are crucial components in GN Solids Control's drilling fluids processing system.

Complementing this solid-phase separation system is the JBQ series mud agitator. This agitator, especially the models below 5.5 kW, employs a blender cycloid speed reducer, making it suitable for drug liquids mixing tanks. Its compact structure ensures minimal space occupation. On the other hand, agitators rated above 7.5 kW utilize a turbo and worm gear speed reducer, offering high torque transmission, stable revolution, and reliable performance. Common models include the JBQ5.5kW, JBQ7.5kW, JBQ11kW, and JBQ15kW. These agitators are crucial components in GN Solids Control's drilling fluids processing system.

Moreover, the GNSB Series centrifugal pump plays a vital role in slurry, mud, or water transfer. It can serve as a feeding pump for desander and desilter or as a mixing pump for Jet Mud Mixer. Additionally, it finds application as a trip pump and supercharging pump for rig mud pumps. All GN model centrifugal pumps feature tungsten carbide mechanical seals and renowned brand bearings, ensuring durability and reliability. Their interchangeable spare parts with most international brand pumps facilitate easy sourcing and maintenance. The pumps' open impeller design reduces axial thrust loads, simplifying installation, repair, and maintenance processes.

Moreover, the GNSB Series centrifugal pump plays a vital role in slurry, mud, or water transfer. It can serve as a feeding pump for desander and desilter or as a mixing pump for Jet Mud Mixer. Additionally, it finds application as a trip pump and supercharging pump for rig mud pumps. All GN model centrifugal pumps feature tungsten carbide mechanical seals and renowned brand bearings, ensuring durability and reliability. Their interchangeable spare parts with most international brand pumps facilitate easy sourcing and maintenance. The pumps' open impeller design reduces axial thrust loads, simplifying installation, repair, and maintenance processes.

GN Solids Control Equipment, with its innovative designs and robust performance, is a trusted choice for Africa's drilling clients. Its desander, desilter, mud agitator, and centrifugal pump offer a comprehensive solution for efficient drilling fluid treatment, ensuring smoother and more cost-effective drilling operations.

- Details

-

Published: 11 April 2024