In the vast landscape of industrial separation equipment, GN Solids Control stands out as a leading manufacturer of decanter centrifuges, dedicated to providing cutting-edge solutions for diverse applications worldwide. Our commitment to excellence is further enhanced by our collaboration with a prominent Swiss supplier, a brand synonymous with innovation in centrifuge hydraulic driving systems. Together, we have developed the GNLW364GT-FHD Food Grade Centrifuge, a full hydraulic drive centrifuge tailored to meet the highest international standards for overseas starch production projects.

The Heart of Innovation: Hydraulic Bowl and Scroll Drive System

The GNLW364GT-FHD centrifuge boasts a sophisticated hydraulic bowl and scroll drive system that powers both the conveyor and bowl through two dedicated hydraulic oil circuits from a single hydraulic pump unit. This meticulously engineered setup ensures seamless operation and robust performance, even under demanding conditions.

Flexibility and Durability in Extreme Environments

A key advantage of the full hydraulic drive centrifuge lies in its ability to thrive in high-temperature environments where heavy mud is processed. The flexible bowl and adjustable differential speed cater to a wide range of operational needs, making it an ideal choice for starch production projects requiring precise separation and high efficiency.

Moreover, the compact skid design of the GNLW364GT-FHD simplifies setup and rig-up processes, reducing downtime and enhancing overall project efficiency. This design philosophy aligns perfectly with the needs of international clients seeking reliable, easy-to-deploy equipment.

The Full Hydraulic System: A Breakdown

The full hydraulic system of the GNLW364GT-FHD centrifuge comprises three essential components:

Hydraulic Pump Unit (A): The heart of the system, this unit supplies hydraulic oil to both the scroll drive (C) and the bowl drive (B) through two separate and independently operating circuits. This ensures redundancy and reliability, minimizing the risk of system failure.

Bowl Drive Hydraulic Motor (B): Driven by hydraulic oil from the pump unit, this motor powers the bowl's rotation, a crucial aspect of centrifuge performance.

Scroll Drive (C): Also powered by hydraulic oil, the scroll drive controls the differential speed between the bowl and the conveyor, facilitating efficient solid-liquid separation.

Independent and Infinite Adjustment Capabilities

At the core of the hydraulic system's versatility lies its ability to allow manual adjustment of both the bowl's rotational speed and the scroll's differential speed independently, continuously, and infinitely variable during operation. This feature is facilitated by an electric motor (A1) driving combined pumps (A2 and A3), each operating circuit equipped with its own hydraulic pump and control system.

The pump unit itself is a marvel of engineering, incorporating all necessary setting devices, safety valves, and pressure gauges to ensure safe, controlled operation. This level of detail and precision ensures that the GNLW364GT-FHD centrifuge can be fine-tuned to meet specific process requirements, optimizing both productivity and product quality.

In conclusion, the GNLW364GT-FHD Food Grade Centrifuge, with its advanced full hydraulic drive system, represents a significant leap forward in starch production technology for overseas projects. By leveraging the combined expertise of GN Solids Control and our Swiss supplier, we have created a machine that not only meets but exceeds the highest industry standards, offering unmatched flexibility, durability, and efficiency. For clients seeking the best in industrial separation equipment, the GNLW364GT-FHD is a clear choice.

- Details

-

Published: 04 October 2024

In a testament toGN Solids Control's relentless pursuit of innovation and customer satisfaction, the company has triumphantly delivered five state-of-the-art trailer-mounted mud tanks to a prestigious client in the Middle East. This momentous occasion marks a significant milestone in GN Solids Control's diverse product development journey, further solidifying its position as a global leader in solids control equipment for the oil and gas industry.

Designed for Harsh Environments, Optimized for Mobility

The trailer-mounted mud tanks designed specifically for the Middle East client are a testament to GN Solids Control's deep understanding of the region's unique challenges. The harsh and demanding environments, coupled with remote and challenging locations, require equipment that combines mobility with rugged durability. These mud tanks exceed these expectations, offering ease of transportation and rapid deployment, which is crucial for projects where time is of the essence.

Quality Craftsmanship Meets Advanced Technology

Crafted from high-quality materials, these mud tanks are engineered to withstand extreme temperatures and endure the toughest conditions. But their strength goes beyond mere durability; the tanks can also be equipped with advanced automation systems, enabling real-time monitoring and precise control of the mud recycling process. This level of technological integration not only enhances operational efficiency but also guarantees a safer and more streamlined workflow.

Maximizing Efficiency, Minimizing Waste

At the heart of these mud tanks lies a sophisticated mud recycling system, featuring a comprehensive suite of equipment such as shale shakers, desanders, desilters, and decanter centrifuges. Working in harmony, these components efficiently separate solids from drilling fluids, minimizing waste and maximizing the reuse of valuable resources. This approach not only reduces the environmental impact of drilling operations but also slashes operational costs, making the entire process more sustainable and economically viable.

Tailored Solutions for Unique Needs

GN Solids Control's commitment to customization is evident in every aspect of these mud tanks. By closely collaborating with the client, the company tailored the tanks to meet their specific requirements, ensuring a perfect fit for the unique challenges of the project. Furthermore, the tanks' compatibility with both water-based and oil-based muds underscores their versatility and adaptability to diverse drilling scenarios.

A Step Forward in Global Expansion

With this successful delivery, GN Solids Control continues to expand its global reach, particularly in the Middle East, where its expertise and solutions are increasingly sought after. This project serves as a powerful demonstration of the company's ability to deliver high-quality, customized solutions that address the specific challenges faced by clients worldwide. It's a testament to GN Solids Control's commitment to excellence, innovation, and above all, customer satisfaction.

In conclusion, the delivery of five trailer-mounted mud tanks to a major Middle East client represents a significant achievement for GN Solids Control. It underscores the company's dedication to pushing the boundaries of solids control technology and providing industry-leading solutions that empower clients to overcome even the most daunting challenges. As GN Solids Control continues to grow its presence in the Middle East and beyond, this milestone project serves as a beacon of hope for a more sustainable, efficient, and profitable future in the oil and gas industry.

- Details

-

Published: 20 September 2024

In the realm of offshore drilling, effective solids control is paramount for maintaining operational efficiency, reducing costs, and ensuring environmental compliance. GN Solids Control, a leading manufacturer based in China, has emerged as a trusted provider of innovative drilling fluid management equipment, including their renowned GN Shale Shaker and GN Mud Cleaner. Let's delve into the details of these game-changing solutions.

GN Shale Shaker: The Backbone of Solids Control

At the heart of any drilling mud solids control system lies the shale shaker. GN Solids Control's Shale Shakers are designed to efficiently remove drill cuttings from the drilling fluid as it circulates through the system. With a wide range of designs and continuous research into optimizing performance, GN Solids Control ensures that their shakers meet the most stringent standards in the oilfield industry.

The basic principle behind these shakers is simple yet effective: a series of large, flat wire mesh screens or sieves of varying mesh sizes shake or vibrate vigorously, causing the drill cuttings (or solids) to be separated from the fluid as it flows through. This process enables the drilling fluid to be recirculated back into the well bore, significantly reducing the need for frequent replacements or costly disposal.

Linear motion shale shakers, particularly popular in oil and gas well drilling, are a specialty of GN Solids Control. These shakers offer superior separation efficiency, making them ideal for rigs worldwide. With a global footprint that includes exports to India, Russia, the Middle East, and beyond, GN Solids Control has earned the trust of prestigious oilfield companies like Oilfield Company of the United States and Century Int'l Oilfield Equipment LLC of the United Arab Emirates.

Backed by an ISO 9001-2000 certified quality management system, GN Solids Control's shale shakers represent a blend of reliability, durability, and cutting-edge technology. Whether you're looking to optimize your drilling fluid management or reduce operational costs, GN Solids Control's shale shakers are the ideal starting point.

GN Mud Cleaner: Enhancing Solids Control to the Next Level

Where GN Solids Control's Shale Shakers handle the initial separation of solids from drilling fluid, the GN Mud Cleaner takes this process to the next level. Also known as a Desander and Desilter assembly, the Mud Cleaner integrates desanders, desilters, and an underflow screen into a single, compact unit.

This two-stage separation process leverages the power of hydrocyclones mounted above the shaker to efficiently remove and dry solids from both weighted and unweighted drilling fluid systems. The hydrocyclones perform the primary separation, directing the underflow onto the shaker's vibrating screen for further refinement.

The GN Mud Cleaner's design ensures that only the most valuable liquid components are retained, minimizing waste and lowering both drilling fluid and disposal costs. In oilfield solids control, the Mud Cleaner is an indispensable tool for maintaining the purity of drilling mud and ensuring the smooth operation of the entire mud purification system.

As an exporter of drilling mud cleaners to India, Russia, the Middle East, and beyond, GN Solids Control has established itself as a go-to supplier for oilfield companies seeking top-quality equipment. With a commitment to quality, service, and innovation, GN Solids Control's Mud Cleaners are the smart choice for any offshore drilling operation looking to enhance its solids control capabilities.

In conclusion, GN Solids Control's GN Shale Shaker and GN Mud Cleaner represent the pinnacle of drilling fluid management technology. Whether you're a seasoned oilfield veteran or a newcomer to the industry, investing in these cutting-edge solutions will help you optimize performance, reduce costs, and protect the environment. Choose GN Solids Control for your drilling fluid management needs – your ideal deal starts here.

- Details

-

Published: 14 September 2024

In the realm of industrial separation technology, the GNLWS364 3 Phase Decanter Centrifuge from GN Solids Control stands as a testament to innovation and efficiency. Designed specifically for the intricate task of simultaneously separating two liquid phases from a solid phase, this advanced machine leverages the powerful force of gravity (G-force) to achieve remarkable results in oil-water separation applications. Today, we delve into the intricacies of this remarkable equipment, tailored for China ES Company and its unique processing needs.

The Essence of 3 Phase Separation

The GNLWS364 3 Phase Decanter Centrifuge operates on a fundamental principle that exploits the inherent differences in densities among immiscible liquids and solids. By harnessing centrifugal force, it ensures that all three phases – two distinct liquid phases and one solid phase – can be efficiently discharged simultaneously. This capability is crucial in industries where purity and efficiency are paramount, such as oil & gas exploration, wastewater treatment, and chemical processing.

Versatile Bowl Sizes for Diverse Needs

Recognizing the diversity of applications, GN Solids Control offers the GNLWS364 in multiple bowl sizes: 360mm, 450mm, and 550mm. This flexibility allows China ES Company to select the optimal model based on their specific throughput requirements and material properties. Whether dealing with high-volume operations or specialized separations, GN ensures that there's a perfect fit for every need.

The Crucial Requirement: Density Differentiation

For the 3 phase separation process to be successful, a crucial prerequisite exists: the solid phase must be the heaviest, while the two liquid phases must exhibit distinct density differences. This condition enables the centrifuge to effectively differentiate between the components and facilitate their separation.

Structural Similarities & Functional Distinctions

At its core, the GNLWS364 shares structural similarities with its two-phase counterparts. However, it distinguishes itself through its innovative approach to liquid discharge. In a 3 phase decanter centrifuge, the higher-density liquid phase is expelled under pressure, ensuring complete and rapid separation. Conversely, the lower-density liquid is discharged without pressure, maintaining its integrity and purity. This dual discharge system ensures optimal separation efficiency and product quality.

A Glimpse into the Working Principle

The heart of the GNLWS364 lies in its precision-engineered design, which maximizes centrifugal force to drive the separation process. As the mixture enters the centrifuge, the rotating bowl accelerates the particles, causing them to separate based on their densities. The heavier solid particles migrate towards the bowl wall, forming a compact layer that's easily discharged. Meanwhile, the two liquid phases, differentiated by their densities, are separated and discharged accordingly – the heavier liquid under pressure and the lighter one without.

Conclusion

For China ES Company and other industry leaders seeking cutting-edge solutions for oil-water separation, the GNLWS364 3 Phase Decanter Centrifuge from GN Solids Control offers an unparalleled combination of efficiency, versatility, and reliability. With its ability to simultaneously separate two liquid phases from a solid phase, this advanced machine stands as a testament to GN's commitment to innovation and excellence in industrial separation technology. As China ES Company embarks on new projects and challenges, the GNLWS364 is poised to be a valuable asset, driving productivity and profitability to new heights.

- Details

-

Published: 06 September 2024

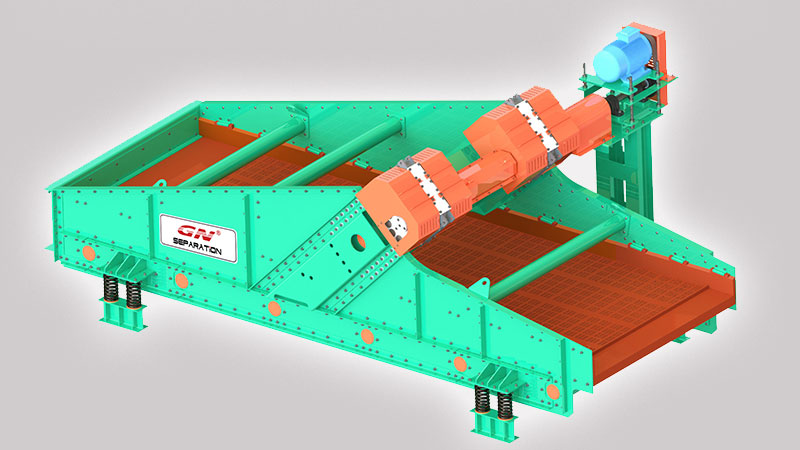

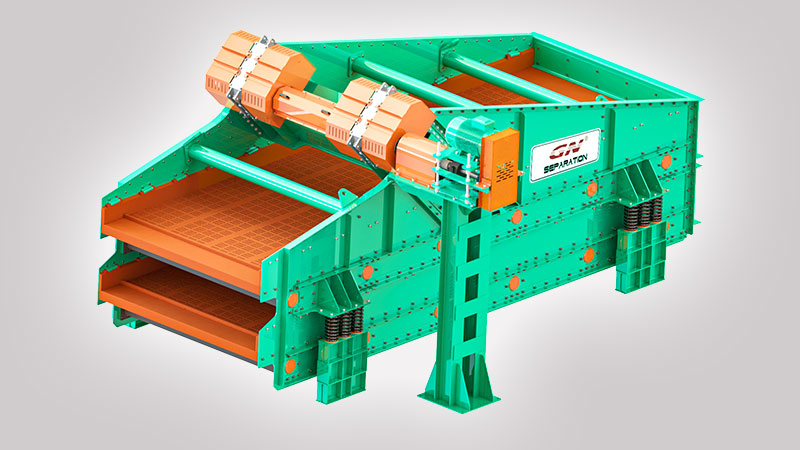

In the vast landscape of industrial screening equipment, the GN Large Linear Vibrating Screen stands out as a reliable and efficient solution for a wide range of applications. This powerful machine, designed with precision and versatility in mind, is a staple in industries such as mineral processing, coal preparation, gravel aggregate, building materials, and the chemical sector. Let's delve deeper into the intricacies of this remarkable machinery.

Introduction to GN Large Linear Vibrating Screen

The GN Large Linear Vibrating Screen is a sophisticated piece of equipment that integrates advanced technology with robust construction. Its core components include a box-type vibration exciter, a sturdy screen box, vibration damping springs, a supportive structure, and a driving device. The unique design ensures that the machine operates with a linear amplitude track, allowing for precise and efficient screening processes.

This versatile screen can be configured horizontally or at an inclined angle, catering to the specific requirements of different industrial processes. Its widespread adoption underscores its ability to handle wet classification, dewatering, demineralization, tailings dry discharge, and numerous other critical process links.

Screen Surface Structure and Customization

The GN Large Linear Vibrating Screen offers flexibility in terms of its screen surface structure, which can be configured as either single-layer or double-layer depending on the screening requirements. This design feature ensures that the machine can be tailored to suit a variety of materials and particle sizes.

Moreover, the model of the screen unit can be customized according to customer specifications. This level of customization ensures that each installation is optimized for maximum performance and efficiency, meeting the unique needs of each industrial application.

Working Principle

The GN Large Linear Vibrating Screen operates on a well-established and highly effective principle. Here's a step-by-step breakdown of its working mechanism:

Forced Synchronization: Equipped with two gearbox vibrators, the screen body is driven to move back and forth in a linear motion. This movement is achieved through the principle of forced synchronization, ensuring smooth and consistent vibration.

Synchronous Vibration: Under the influence of the exciting force generated by the vibrators, the screen surface vibrates synchronously. This vibration is transmitted to the materials placed on the screen, causing them to be thrown up and layered on the screen surface.

Screening and Grading: As the materials are impacted and thrown up, they are screened and graded according to their specified particle sizes. The continuous buffering and input of materials from the feeding trough to the receiving plate ensure a seamless screening process.

Material Discharge: The screened materials are then discharged into separate receiving troughs located above and below the screen surface. This separation facilitates the easy transfer of materials to the next process link.

Adjustable Inclination Angle: The included angle between the direction of the exciting force and the horizontal plane can be designed specifically for the materials being processed. This angle plays a crucial role in determining the running speed of the materials on the screen surface and, consequently, the overall processing capacity of the equipment.

Cnclusion:

The GN Large Linear Vibrating Screen is a testament to the fusion of advanced technology and robust engineering from GN Separation. Its versatility, precision, and customization options make it an invaluable asset for industries that rely on efficient and reliable screening processes. Whether it's mineral processing, coal preparation, or gravel aggregate production, this machine consistently delivers outstanding performance, ensuring that materials are screened and graded to the highest standards.

- Details

-

Published: 30 August 2024