- Details

-

Published: 30 August 2024

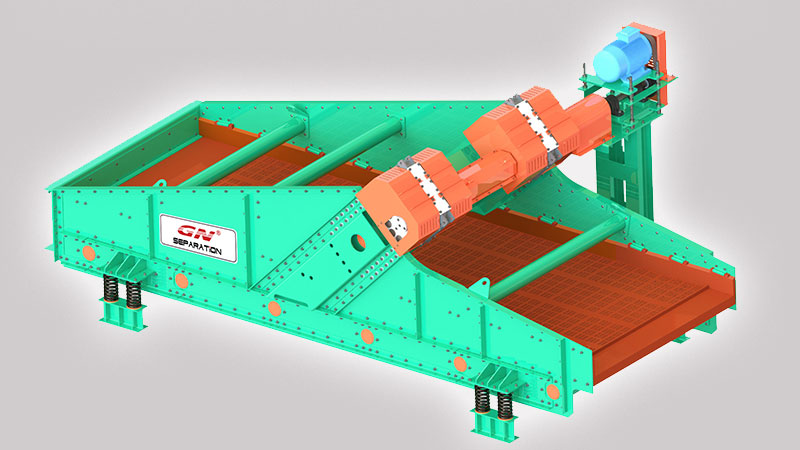

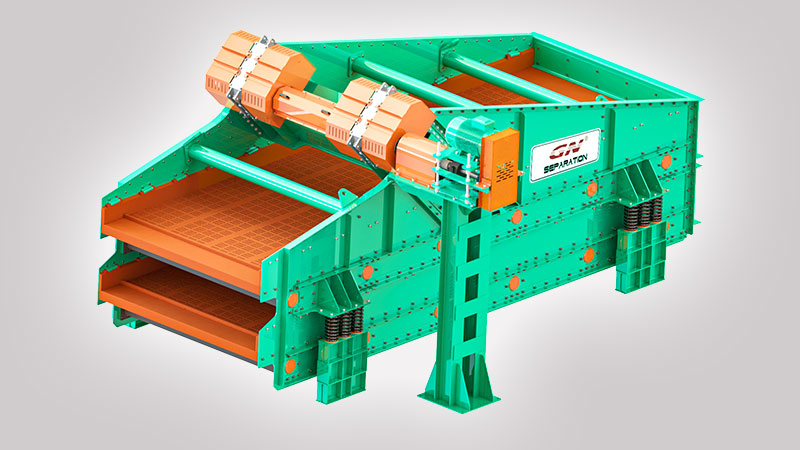

In the vast landscape of industrial screening equipment, the GN Large Linear Vibrating Screen stands out as a reliable and efficient solution for a wide range of applications. This powerful machine, designed with precision and versatility in mind, is a staple in industries such as mineral processing, coal preparation, gravel aggregate, building materials, and the chemical sector. Let's delve deeper into the intricacies of this remarkable machinery.

Introduction to GN Large Linear Vibrating Screen

The GN Large Linear Vibrating Screen is a sophisticated piece of equipment that integrates advanced technology with robust construction. Its core components include a box-type vibration exciter, a sturdy screen box, vibration damping springs, a supportive structure, and a driving device. The unique design ensures that the machine operates with a linear amplitude track, allowing for precise and efficient screening processes.

This versatile screen can be configured horizontally or at an inclined angle, catering to the specific requirements of different industrial processes. Its widespread adoption underscores its ability to handle wet classification, dewatering, demineralization, tailings dry discharge, and numerous other critical process links.

Screen Surface Structure and Customization

The GN Large Linear Vibrating Screen offers flexibility in terms of its screen surface structure, which can be configured as either single-layer or double-layer depending on the screening requirements. This design feature ensures that the machine can be tailored to suit a variety of materials and particle sizes.

Moreover, the model of the screen unit can be customized according to customer specifications. This level of customization ensures that each installation is optimized for maximum performance and efficiency, meeting the unique needs of each industrial application.

Working Principle

The GN Large Linear Vibrating Screen operates on a well-established and highly effective principle. Here's a step-by-step breakdown of its working mechanism:

Forced Synchronization: Equipped with two gearbox vibrators, the screen body is driven to move back and forth in a linear motion. This movement is achieved through the principle of forced synchronization, ensuring smooth and consistent vibration.

Synchronous Vibration: Under the influence of the exciting force generated by the vibrators, the screen surface vibrates synchronously. This vibration is transmitted to the materials placed on the screen, causing them to be thrown up and layered on the screen surface.

Screening and Grading: As the materials are impacted and thrown up, they are screened and graded according to their specified particle sizes. The continuous buffering and input of materials from the feeding trough to the receiving plate ensure a seamless screening process.

Material Discharge: The screened materials are then discharged into separate receiving troughs located above and below the screen surface. This separation facilitates the easy transfer of materials to the next process link.

Adjustable Inclination Angle: The included angle between the direction of the exciting force and the horizontal plane can be designed specifically for the materials being processed. This angle plays a crucial role in determining the running speed of the materials on the screen surface and, consequently, the overall processing capacity of the equipment.

Cnclusion:

The GN Large Linear Vibrating Screen is a testament to the fusion of advanced technology and robust engineering from GN Separation. Its versatility, precision, and customization options make it an invaluable asset for industries that rely on efficient and reliable screening processes. Whether it's mineral processing, coal preparation, or gravel aggregate production, this machine consistently delivers outstanding performance, ensuring that materials are screened and graded to the highest standards.