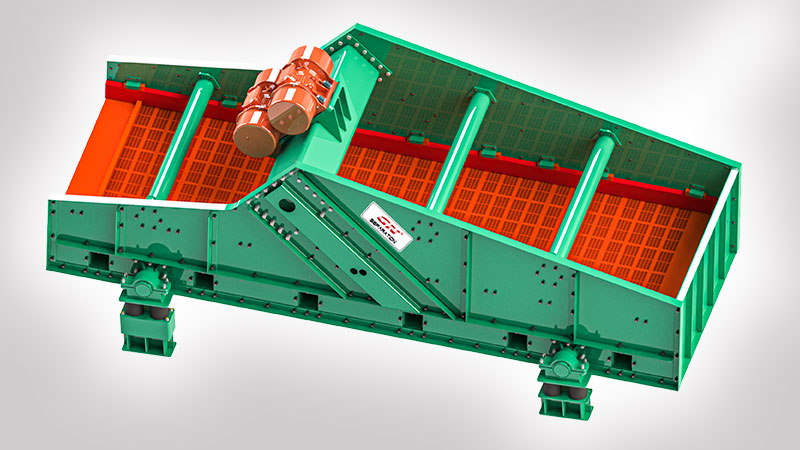

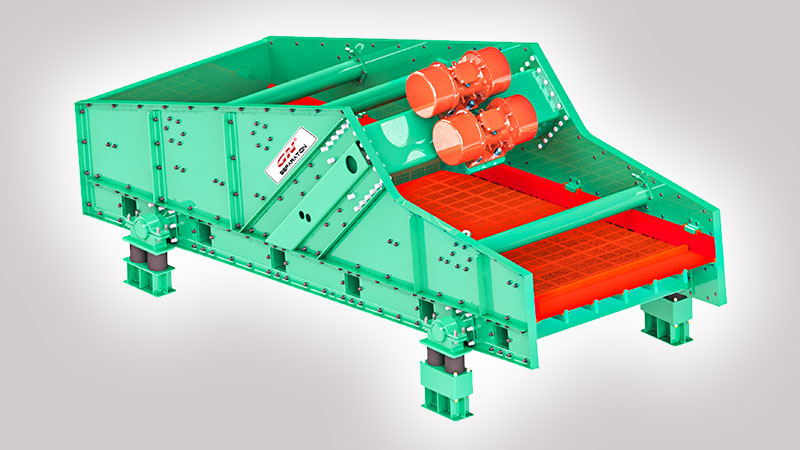

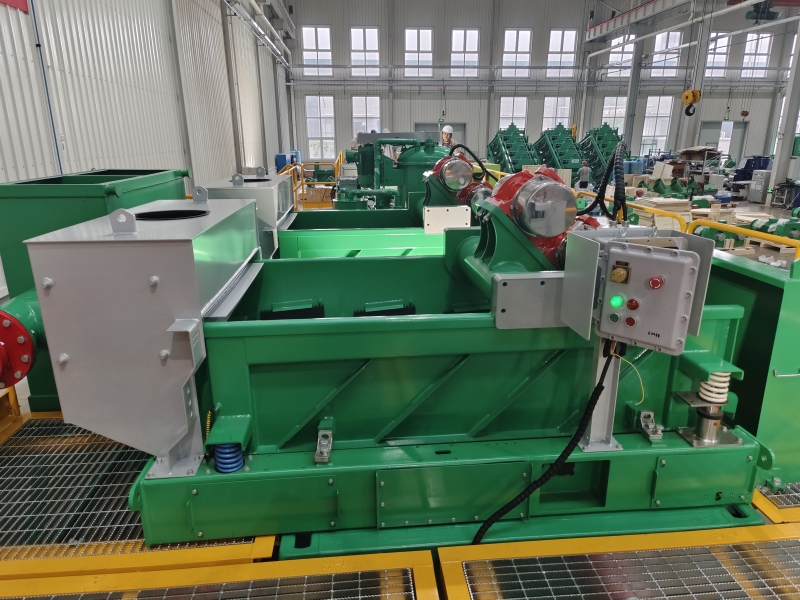

GN proudly present: Classification Vibrating Screen. Extensively utilized in the classification and screening of various materials, including iron ore, coal, non-ferrous metal ore, building materials, and products from the chemical industry, this equipment incorporates advanced design techniques, such as finite element analysis and anti-fatigue analysis, to ensure a reasonable structure, low energy consumption, and a substantial screening and classification capacity. It is adept at functioning in diverse working conditions that are prone to corrosion and wear, demonstrating large processing capacity, high efficiency, and stable performance. Notably, the size of the screen machine can be customized to meet specific customer requirements.

Equipped with two vibrating motors, the GN Classification Vibrating Screen operates by utilizing the principle of reverse self-synchronization, enabling the screen body to move in a linear line. The screen body drives the screen panel to vibrate synchronously, transmitting force to the materials on the panel. This action impacts the materials, causing them to be thrown up on the screen surface for layering. Subsequently, the materials are graded according to the specified particle size as they pass through the screen.

Equipped with two vibrating motors, the GN Classification Vibrating Screen operates by utilizing the principle of reverse self-synchronization, enabling the screen body to move in a linear line. The screen body drives the screen panel to vibrate synchronously, transmitting force to the materials on the panel. This action impacts the materials, causing them to be thrown up on the screen surface for layering. Subsequently, the materials are graded according to the specified particle size as they pass through the screen.

The GN Classification Vibrating Screen boasts several notable features:

The GN Classification Vibrating Screen boasts several notable features:

Advanced Wallboard Design: The wallboard is not welded. Instead, it is constructed using a steel plate with enhanced impact toughness and cold bending properties. It is assembled using imported HUCK rivets for hydraulic tension, eliminating welding residual stress and material defects. This design prevents the reduction of fatigue strength in the wallboard due to such defects.

Optimized Structural Strength: Through finite element analysis, the structural strength and vibration quality of the screen machine are optimized to the fullest extent, reducing stress and prolonging the equipment's service life.

Durable Fluids-Touching and Wear Parts: The fluids-touching parts and easily worn components are sprayed with polyurea using a spraying machine imported from the United States. This coating is corrosion-resistant, erosion-resistant, and wear-resistant.

Effective Post-Weld Treatment: The main components undergo a post-weld heat treatment process, which effectively eliminates welding stress.

Product Serialization and Modular Design: The product is serialized to meet manufacturing requirements under different process conditions. The polyurethane screen panel is modular, providing versatility and convenience during replacement.

Adjustable Installation Angle: The whole machine is installed at a positive inclination angle, with the installation angle adjustable up to 4 degrees. This adaptability suits the requirements of different process materials.

Optimized Screen Surface Design: The plane design of the entire screen surface facilitates screening and grading materials, maximizing the effective screening area.

Rubber Damping Spring Design: This design offers advantages such as good damping effect, low noise, a small resonance field, good resilience, stable mechanical performance, long service life, and low cost.

- Details

-

Published: 23 August 2024

In the midst of growing global energy demand, efficient and environmentally friendly oil and gas extraction technologies have become the focal point of the industry. Recently, GN Solids Control announced the successful signing of a contract to sell its top-notch hydraulic centrifuges, the GNLW363D-FHD series, and high-efficiency cuttings dryers, the GNCD930G, in bulk to a renowned Asian oilfield services company. This marks another significant achievement for GN in the offshore oil and gas equipment sector.

The six GNLW363D-FHD hydraulic centrifuges delivered feature remarkable separation efficiency, low energy consumption design, and highly automated control systems, earning them high praise from the customer. These units efficiently process the substantial quantities of mud mixtures generated during drilling operations, rapidly separating drilling fluids from solid particles, significantly enhancing drilling efficiency and safety. Furthermore, their eco-friendly characteristics align with the current global emphasis on green extraction practices.

The six GNLW363D-FHD hydraulic centrifuges delivered feature remarkable separation efficiency, low energy consumption design, and highly automated control systems, earning them high praise from the customer. These units efficiently process the substantial quantities of mud mixtures generated during drilling operations, rapidly separating drilling fluids from solid particles, significantly enhancing drilling efficiency and safety. Furthermore, their eco-friendly characteristics align with the current global emphasis on green extraction practices.

Moreover, the two GNCD930G cuttings dryers complement the offering impressively. Leveraging advanced dehydration technology, they efficiently remove water from cuttings, reducing waste volume and facilitating subsequent treatment and transportation, ultimately lowering operational costs and minimizing environmental impact.

Worth mentioning is the inclusion of eight high-performance screw pumps in this order. These pumps, with their stable delivery capabilities and corrosion resistance, provide a solid foundation for the smooth operation of the entire drilling system.

GN's successful contract signing underscores its profound capabilities and technological innovation in the offshore oil and gas equipment industry, contributing significantly to the green development of the oil and gas extraction sector in Asia and globally. Looking ahead, GN will continue to uphold its development philosophy of "Innovation, Efficiency, and Environmental Protection," offering more premium offshore oil and gas equipment solutions to customers worldwide.

- Details

-

Published: 16 August 2024

In the realm of mineral processing and industrial separation, the GN High Shear Circular Screen, a masterpiece crafted by GN Separation, stands as a testament to innovation and efficiency. This advanced screening solution is tailored to meet the rigorous demands of overseas silicon sand classification projects, ensuring precision, durability, and unparalleled performance.

![]()

The Heart of the Machine: The Long Vibrating Motor

At the core of the GN High Shear Vibrating Screen lies a long vibrating motor, serving as its sole excitation source. This motor generates a sinusoidal inertia force that revolves around a fixed axis and direction, propelling the screen deck assembly into a smooth, circular motion. This unique design not only ensures stable and efficient screening but also minimizes wear and tear on the system, extending its service life.

High-Frequency, High-Amplitude Operation

Operating at frequencies of up to 25Hz, the GN High Shear Circular Screen boasts a double vibrating amplitude ranging from 2 to 4mm. This combination of high frequency and amplitude translates into increased screening capacity and improved separation efficiency. Whether dealing with coarse or fine-grained silicon sand, the screen consistently delivers optimal results, ensuring that product quality remains consistent throughout the classification process.

Versatile Screen Area and Mesh Options

Recognizing the diverse needs of overseas silicon sand projects, the GN High Shear Vibrating Screen offers two screen area options: 2.8m² and 5.6m², achieved through the use of 4 or 5 screen meshes respectively. These meshes are crafted from high-quality polyurethane, specifically engineered to resist blockages and maintain a high opening rate of 28% to 45%. With mesh sizes ranging from 0.045 to 2mm, the screen can be tailored to suit a wide variety of particle sizes, making it an ideal choice for silicon sand classification and beyond.

Designed for Durability and Maintenance

The GN High Shear Circular Screen is built to withstand the harsh conditions of industrial environments. Its robust construction and high-quality materials ensure that it remains operational even under heavy loads and extended use. Furthermore, the screen's modular design facilitates easy maintenance and replacement of worn parts, minimizing downtime and maximizing productivity.

Conclusion

For overseas silicon sand classification projects seeking a reliable, efficient, and durable screening solution, the GN High Shear Circular Screen is the answer. With its long vibrating motor, high-frequency operation, versatile screen area and mesh options, and robust construction, this screen is poised to revolutionize the way silicon sand is processed and classified. GN Separation's commitment to innovation and quality ensures that every project, no matter how challenging, can benefit from the exceptional performance of the GN High Shear Circular Screen.

- Details

-

Published: 09 August 2024

In the dynamic landscape of industrial separation, GN stands as a pioneering force, designing and manufacturing both decanter centrifuges and three-phase centrifuges that redefine industry standards. Our commitment to innovation extends beyond the conventional, as we delve into the heart of separation technology to craft solutions tailored to the unique demands of our clients.

A Legacy of Solid Bowl Decanter Centrifuges

Tracing its roots back to the 19th century, the solid bowl decanter centrifuge has stood the test of time, operating on a fundamental principle that has been refined and perfected over generations. At GN, we honor this legacy by integrating modern advancements into our designs, ensuring that each decanter centrifuge we produce embodies the essence of reliability and efficiency.

Customized Solutions for Specialized Separation Tasks

Recognizing that no two separation tasks are alike, GN specializes in designing centrifuges that are tailored to specific applications. Our use of resilient, high-quality materials not only enhances the durability of our equipment but also significantly boosts its performance. This commitment to precision engineering ensures that our centrifuges deliver unparalleled results, even under the most challenging conditions.

PLC & Electrical Control System Expertise

At the heart of every GN centrifuge lies our state-of-the-art PLC and electrical control system, designed and developed in-house. This vertical integration gives us a distinct advantage in measuring and control technology, allowing us to fine-tune every aspect of the machine's operation. The result is a control system that significantly improves the performance and availability of both decanter and three-phase centrifuges, ensuring seamless and efficient separation processes.

Introducing the GN 22-inch Big Bowl Decanter Centrifuge

For Asia Oilfield Service Company, we proudly present the GN 22-inch (550mm) bowl diameter decanter centrifuge – a high-capacity marvel that redefines the limits of industrial separation. Available in two bowl length-to-diameter ratios (3.3:1 or 4.2:1), this centrifuge offers unparalleled flexibility to suit a wide range of applications.

Powered by the most reliable and robust electrical components, sourced from industry leaders like ABB or SIEMENS, our 22-inch centrifuge is equipped with a Fully Variable Speed VFD control system. This advanced technology enables electronic load sensing and feed pump control, allowing for automatic optimization of feed rate, bowl speed, and differential conveyor speed.

For ultimate operator convenience, the centrifuge features direct readouts of bowl RPM, motor loads, and bearing temperatures (optional), relayed directly to the control panel. This continuous monitoring and optimization capability empower operators to maintain peak performance and maximize equipment efficiency.

In conclusion, the GN 22-inch big bowl decanter centrifuge is a testament to our commitment to innovation and excellence in industrial separation. Designed specifically for Asia Oilfield Service Company, this high-capacity centrifuge represents the pinnacle of our engineering prowess and is poised to revolutionize the way oilfield services are delivered in Asia.

- Details

-

Published: 02 August 2024

In the vast and dynamic oil and gas exploration landscape of Africa, the efficiency and reliability of drilling operations are paramount. At the heart of these endeavors lies the Workover Drilling Rig Mud Tank System, a crucial component that ensures the smooth flow of drilling fluids and the effective removal of contaminants. At GN Solids Control, we have engineered a comprehensive mud tank system tailored specifically for the challenging conditions of Africa, with a focus on two cornerstone technologies: Shale Shakers and Vacuum Degassers.

Shale Shakershale Shakers: The Foundation of Solids Control

At the forefront of our mud tank system stands the Shale Shaker, the initial and vital stage in the drilling fluids processing system. Renowned as the cornerstone of solids control in the drilling mud system, the Shale Shaker sets the tone for the entire solids control process. Recognizing the diverse needs of our clients, GN Solids Control offers customized solutions, including double and triplicate shakers mounted on a single skid, tailored to specific requirements.

Our GNZS Linear Motion Shale Shakers embody the fusion of global advancements and GN's proprietary design. This series boasts high G-force, expansive screen areas, compact structures, and cost-effectiveness, all of which have been validated by the overwhelmingly positive feedback from our clients. Whether it's the third-generation linear motion model or the fourth-generation balanced elliptical variant, GN Solids Control ensures that every shaker meets the highest standards of performance and durability.

Vacuum Degasser: The Key to Gas Elimination

Complementing the Shale Shakers is the ZCQ Series Vacuum Degasser, a specialized and innovative device designed to tackle the issue of gas contamination in drilling fluids. This cutting-edge technology efficiently eliminates various types of intrusive gases, thereby restoring mud gravity, stabilizing mud viscosity, and ultimately reducing drilling costs. What's more, the Vacuum Degasser doubles as a powerful agitator, making it a versatile addition to any mud circulation purification system.

The scientific and rational design of our Vacuum Degasser ensures effective gas-liquid separation, thorough impurity filtration, and smooth exhaust flow. This not only enhances the overall performance of the drilling process but also contributes to a safer and more sustainable operational environment.

Conclusion

At GN Solids Control, we understand that the success of Africa's oil and gas exploration endeavors hinges on reliable and efficient drilling equipment. Our Workover Drilling Rig Mud Tank System, with its cutting-edge Shale Shakers and Vacuum Degassers, represents a quantum leap in solids control and gas elimination. We are committed to providing tailored solutions that meet the unique challenges of Africa's drilling landscape, empowering our clients to achieve unparalleled operational excellence.

- Details

-

Published: 26 July 2024