GN Solids Control has been working on designing and manufacturing turn-key solids control and drilling slurry treatment solutions for many years. With more and more GN equipment and treating systems successfully used in customers’ work site, there’re more inquires on solids control treating systems.

Just several weeks before, GN Solids Control won a large order of 1000GPM solids control treating systems from one European drilling customer. There are many strict rules and regulations need to meet in order to win this tender, eventually, GN Solids Control left a pretty professional experience for customers.

Although there are still many technical details need to be further discussed, GN Solids Control is pretty confident to provide another satisfied cost-effective solids control system. Typical, GN Solids Control System includes the following part:

1. Shaker Tank

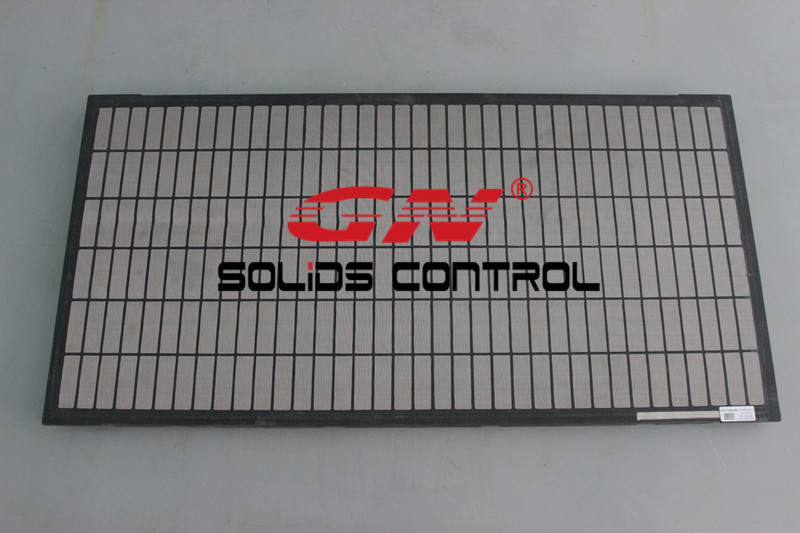

GN Shale shakers are usually used by 2 sets or 4 sets. Considering the maintenance and shaker screen changing, it’s better to have 2 backup shale shakers. Due to GN Solids Control are manufacturing the most cost-effective shaker screens, so from the long run, drilling companies will save a lot on shaker screens investment as they are wearable parts and need to change frequently. GN Mud Cleaners (include GN desander cyclones and GN desilter cyclones) are also used. After treating by GN shaker tank, solids larger than 25 microns can be separated out.

2. Centrifuge Tank

Decanter centrifuges are all commonly used. Generally speaking, one middle rotating speed centrifuge and one high rotating speed centrifuge will be used. The first one is used to separated out most of the solids. While the second centrifuge also called polishing centrifuge is used to eliminate those much finer solids.

3. Mud Mixing Tank

After treated by above equipment, GN mud mixing tanks are used to prepare new drilling mud. A GN Jet Mud Mixer is common seen to add drilling additives and make new drilling mud.

4. Mud Storage Tank

Mud storage tank will stock those new drilling mud and keep them agitating. New drilling mud can be reused.

- Details

-

Published: 18 May 2017

As a branch company of GN Solids Control, GN Solids America LLC has been in Houston, TX for almost 4 years. Although GN Solids America LLC is still a baby company, with the great help from GN Solids Control, GN Solids America is getting known by more and more solids control and waste management customers.

Now GN Solids Control manufactures 9 inch centrifuge, 14inch centrifuge, 18inch centrifuge, 22inch centrifuge and 30 inch centrifuge. Different models can be used in different areas due to the treating volume and G force differences.

Such as the barite recovery, most of the solutions we provided to our customers are dual centrifuge systems, sometimes 3 centrifuges might needed. Here is one typical (probably the most cost effective) barite recovery solution:

1. One 18inch middle rotating speed centrifuge GNLW452 (815 G force @1800 rpm), this is used to recovery barite or separate out High gravity solids.

2. One 14inch high rotating speed centrifuge GNLW363 (2062 G force @3200RPM), this is for separating out low gravity finer solids.

Frankly speaking, GN 30inch centrifuges are mainly used on TBM drilling slurry separation or some other industry slurry treatment areas. Treating capacity is 528GPM (mud with 20% solids). It's not common to use it in the oil and gas area as they don’t have such large drilling rigs.

GN Solids Control has provided centrifuges to more than 60 countries, with the successful usage by many large customers such as Shell, Baker Hughes, Bariod etc. If you are looking for the small centrifuge like 14inch, 18inch and 22inch, we do can provide you with hundreds of successful projects. According to our former experience, when the mud weight below 11ppg almost all the customers are not collecting them.

Now GN Houston warehouse has many centrifuges in stock, welcome to check our Houston warehouse for your decanter centrifuge needs.

- Details

-

Published: 11 May 2017

The world largest oil and gas show, OTC is just around the corner, GN Solids Control and GN Solids America LLC will participated in this great show and have two separate booths.

GN Solids Control has been attending the OTC (offshore technology conference) since 2011, now it’s become a tradition for GN Solids Control to participate in the OTC show every year. As the most influential show for oil & gas industries, OTC has over thousands exhibitors attended every time. There are three exhibition halls: Center, Arena and Stadium in NRG park, Houston, TX.

As usual, GN Solids Control will have a large booth in Center and in a standard booth in Arena. GN Solids Control is only devoted to designing and manufacturing various separation equipment and systems. GN Solids Control is getting to know by most of the oil and gas companies especially by those solids control and waste management companies and professionals. GN Solids Control only provides the most cost-effective equipment to global customers. Many large customers are using GN Solids Control equipment to do the solids and liquid separation work and they actually perform excellently well. As a world equipment provider, GN Solids Control products now have been widely used in more than sixty countries.

This year, GN Solids Control will exhibit the upgraded shale shaker. GN Solids Control engineers are very professional to provide the best solutions, every year GN Solids engineers are sent to global worksites and collect valuable working performance data. Based on that, GN engineers will modify or upgrade all GN Solids Control equipment accordingly. GN Solids Control engineers are always trying to offer the most cost –effective separating solutions.

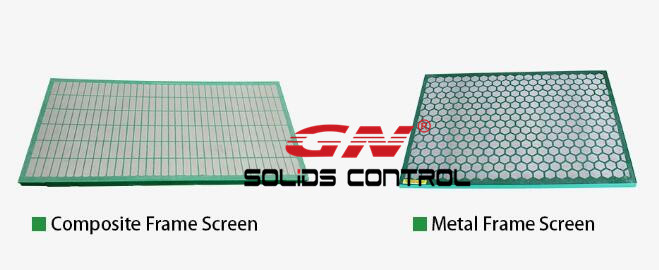

Various shake screens will be also exhibited in the OTC show. GN Solids Control now manufacture over 5000 pieces shaker screens, with the opening of the No.2 factory, GN Solids Control now can manufacture all flat panel shaker screens with composite material which means the metal frame screens are also coated by high quality composite material.

- Details

-

Published: 13 April 2017

GN Solids Control is one of the most famous leading manufacturers for separation equipment. Solids Control and waste management systems are widely used in over 60 countries. Now over 5000 pieces shaker screens are manufactured by GN Solids Control every month. Besides those above solids control and waste management equipment, GN Solids Control also provides shaker screen production line.

As the shaker screens are manufactured in two methods: one manufacturing way is by using mould injecting production line, the other is using power coating production line. Due to the composite frame shaker screen's patent issue, no manufacturer in North America can manufacture composite screens. So the mould injecting production line cannot be used in North America. While for the powder coating manufacture line, it is totally OK to operate the manufacture in North America. GN Solids Control has already provided several sets of the manufacture line to some customers. Different shaker screens mould is provided. Customers only need to purchase the screen cloth, and GN Solids Control will put the specified screen cloth (2 or 3 layers) in sequence in order to form the API no (which also means the conductance point, separating room etc).

Due to the Composite Frame screens (made by Injection Molding) patent owned by Mi-Swaco, we recommend to manufacture metal frame screens in USAGN shaker screen production line includes the following equipment:

1. Metal Cutting (Nesting) Machine

2. Bending Machine

3. Punching Machine

4. Sand Blasting Machine

5. Thermal Drying Tunnel

6. Plastic Coating Machine

7. Heat Pressing Machine

GN Technical Support to teach your people make shaker screens and onsite commissioning is included in the whole purchase price. While accommodation, food and travel cost should be covered by your company. Two workers for production about 100Pcs of shaker screens within one working day. Robot can be also used for metal frame welding also helps to guarantee the manufacturing consistency.

- Details

-

Published: 15 March 2017

As a well-known solids control and waste management manufacturer, GN Solids Control has been working on designing and manufacturing thousands of separation equipment for many years. More and more customers are willing to choose GN Solids Control equipment for their separation needs.

The business volume of GN Solids Control is 120,000,000 RMB which is around 20,000,000 USD. GN Solids Control only devoted to provide the most cost effective equipment on solids and liquid separation. Now GN Solids Control has over 150 employees, most of them are professionals who have been working on solids control and waste management equipment manufacturing for over 10 years. GN Solids Control chief engineer has more than 25 years’ experience in the oil and gas solids control area.

In 2007, GN Solids Control was built in Tangshang from a small workshop. In October 2010, GN Solids Control moved to the new manufacturing plant in Dachang Industrial Development Area which is pretty close to Beijing International Airport. In 2014, GN Solids America LLC was established in Houston, USA with a large warehouse. In 2015, GN Solids Russia was established to serve the Russia customers. In 2016, GN Solids Control opened another factory near its headquarters.

GN Solids Control has been experiencing the fastest development with the pretty active of drilling rigs’ development. GN Solids Control’s great success is mainly based on we only provided the equipment that we are very good at to manufacture. The best advertisement is word of mouth. GN Solids Control provides the best after sales service.

GN Solids Control is always trying to stand on the tide of high technology. Many new developed equipment are provided in order to meet customers’ changing demands. Take the example of TDU, GN Solids Control has been working on designing of TDU since February 2015. And the first TDU was built in Jan. 2017, it will be put into use in July 2017.

- Details

-

Published: 12 March 2017