As a well-known solids control and waste management manufacturer, GN Solids Control has been working on designing and manufacturing thousands of separation equipment for many years. More and more customers are willing to choose GN Solids Control equipment for their separation needs.

The business volume of GN Solids Control is 120,000,000 RMB which is around 20,000,000 USD. GN Solids Control only devoted to provide the most cost effective equipment on solids and liquid separation. Now GN Solids Control has over 150 employees, most of them are professionals who have been working on solids control and waste management equipment manufacturing for over 10 years. GN Solids Control chief engineer has more than 25 years’ experience in the oil and gas solids control area.

In 2007, GN Solids Control was built in Tangshang from a small workshop. In October 2010, GN Solids Control moved to the new manufacturing plant in Dachang Industrial Development Area which is pretty close to Beijing International Airport. In 2014, GN Solids America LLC was established in Houston, USA with a large warehouse. In 2015, GN Solids Russia was established to serve the Russia customers. In 2016, GN Solids Control opened another factory near its headquarters.

GN Solids Control has been experiencing the fastest development with the pretty active of drilling rigs’ development. GN Solids Control’s great success is mainly based on we only provided the equipment that we are very good at to manufacture. The best advertisement is word of mouth. GN Solids Control provides the best after sales service.

GN Solids Control is always trying to stand on the tide of high technology. Many new developed equipment are provided in order to meet customers’ changing demands. Take the example of TDU, GN Solids Control has been working on designing of TDU since February 2015. And the first TDU was built in Jan. 2017, it will be put into use in July 2017.

- Details

-

Published: 12 March 2017

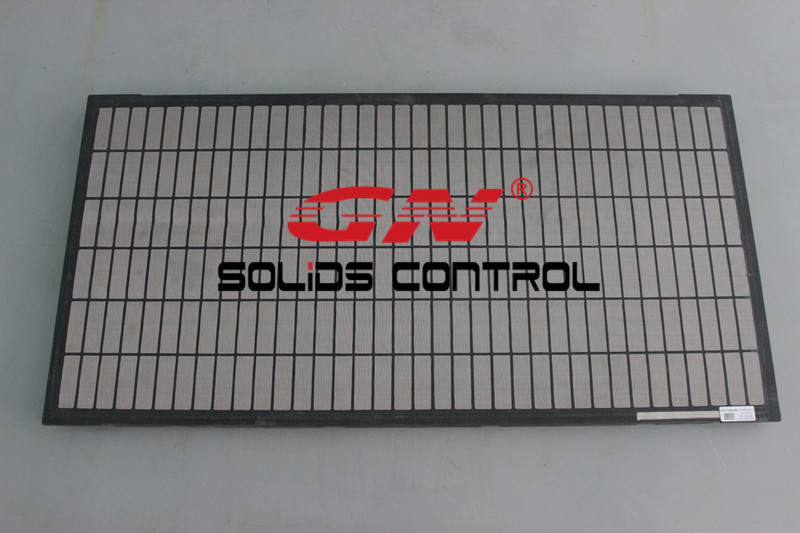

GN Solids Control has been manufacturing variety shaker screens for thousands of customers from over 60 countries. GN Solids Control is a leading manufacturer for shaker screens. GN Solids Control now is providing replacement shaker screen such as Mongoose, Derrick, Venom, KPT etc.

Besides those standard shaker screens GN Solids Control manufactures, GN Solids Control also manufactures customized shaker screens based on customers’ special demands. Customers just need to provide us with the size of the shaker screens and several pictures, a sample will be more helpful.

To start manufacture, GN Solids Control will charge the manufacturing cost of making new mould. Once customers’ purchase reach to certain amount, GN Solids Control would like to reimburse customers with the shaker screens that with the value of new mould. So it means that GN Solids Control will eat the cost of the new mould by ourselves eventually. GN Solids Control made Composite Frame screens can be stocked for a much longer time compared to the traditional metal frame ones. Their life time is 20~30% longer, and the effective working room is larger than the metal ones. And for these newly made screens, we can put customer's Logo and API tag on our screens.

As you know, shaker screens are wearable parts, they need to throw away after they have been used for some days. Now GN Solids Control manufactures over 5000 pieces shaker screens every month, and GN shaker screens are exported to over 60 countries. Many large customers are using GN shaker screens, like Baker Hughes, Barid, Shell etc. Detail shaker screen presentation can be provided.

Compared to other manufactures, GN Solids Control shaker screens are more cost-effective. You can place a trial order on order to know our shaker screens quality. We have many customers keep purchasing from us, many screens are available in Houston warehouse, just come to check our warehouse if you want to find the most cost-effective shaker screens.

- Details

-

Published: 04 March 2017

GN Solids Control is a famous solids control and waste management manufacturer. As the leading provider for separation equipment, GN Solids Control not only manufacture shaker screens, but also provides thousands of solids control equipment and waste management systems to more than sixty countries.

Just several weeks before, GN Solids Control got a large order on solids control equipment, includes 10 sets shale shaker, 10 sets decanter centrifuges and various centrifugal degassers. Those equipment will be used in Russia drilling rig site. All those equipment are provided with the lead time of only 15 days as GN Solids Control has many shale shakers and decanter centrifuges in stock.

1. GN Shale Shaker

GNZS593E-HB is one new model which only has 3 panel shaker screens. This new type shaker is using the same size shaker screens as Mi-Swaco Mongoose. With the compact design, GNZS593E-HB shaker can be using in narrow working room. Shale shaker is also using two brands based on customers’ option: one is USA Martin and the other is Italy brand OLI.

2. GN Decanter Centrifuge

GN decanter centrifuge is one of the core products for solids and liquid separation. GN 14inch size rotating bowl decanter centrifuge GNLW363 is one the most popular products that largely used in drilling rig site. VFD control panel and fix speed control panel are optional based on customers’ demands. The VFD control panel is more smart and convenient compared to the fixed speed control box. All the parameter can be changed easily by using the HMI.

3. GN Centrifugal Degasser

GN centrifuge degasser is GN newly developed product, it mostly suitable for the compact working room compared with the vacuum degasser. GN also manufactures poor boy degasser to eliminate most of the air when the drilling mud comes from drilling rigs.

GN Solids Control is always devoted to provide the best quality products. We hold the principle that only the market can tell customer what’s the most cost effective solids control and waste management products.

- Details

-

Published: 25 February 2017

GN Solids Control has two manufacturing plants in China. They are both pretty close to Beijing International Airport. Now GN second manufacturing plant is mainly manufacture shaker screens. Most of GN Solids Control’s shaker screens are using outside of China. Until now, GN Solids Control has delivered shaker screens to customers from over 60 countries.

GN Solids Control manufactures the most cost effective shaker screens. GN Screens can be used to replace Mi-Swaco screens, Derrick Screens, NOV Brant Screens and King Cobra Screens, Fluids System Screens as well as Kemtron Screens. GN Solids Control shaker screens are totally interchangeable with those original shaker screens, all GN made screens have the exact same size as the original screens.

In 2016 GN Solids America LLC increased the stock volume of shaker screens in Houston warehouse. This year, GN Solids America LLC will stock more screens in Houston for fast delivery. In the next several days, GN Solids America will receive a 40 ft container full of shaker screens, most of them are replacement screens for Mi-Swaco Mongoose and NOV King Cobra/ Venom screens.

Now GN mainly stock composite frame shaker screens in Houston. Generally speaking, GN Solids Control’s composite frame screens’ life period is 20~30% longer than the metal frame screens, and the conductance feature of GN Composite Frame Screens are much better than the frame screens.

Inside the GN composite shaker screens, there are metal frame which are welded by robot welding machine. Most of GN competitors are using 2 layers screen cloth below API 120, while GN Solids are using 3 layers for all those screens above API 50.

GN Solids Control is always devoted to provide the best quality products to the global customers. As the first API certified manufacturer from China, GN Solids Control is also the first on to build one Solids Control branch company in USA. Besides, GN Solids Control also has one branch company in Russia. Many partners are also working very closely with GN Solids and provide after sales service on behalf of GN Solids.

- Details

-

Published: 16 February 2017

The 2017 CIPPE is coming near, GN Solids Control will participate in this great show. As the top manufacturer on solids control and waste management equipment, GN Solids Control has been attending this great show for many years.

CIPPE is short for China International Petroleum & Petrochemical Technology and Equipment Exhibition, every year many oil and gas companies will come to this show and exhibit newly developed equipment, new technology and concept will also be shared. This is a great show for oil and gas professionals.

GN Solids Control has been participating in the Beijing CIPPE show for many years, and GN Solids Control also attends the Shanghai oil show in the next half year.

This year, GN Solids Control will exhibit some newly developed equipment in Beijing CIPPE. GN booth is E2218, this show will exhibit from March 20th to March 22nd, 2017. For customers if you want to visit our booth, please feel free to connect with GN. As GN factory is pretty close to Beijing International Airport and the Exhibition Center, we can show you around our factory.

This year, GN Solids Control will exhibit the following equipment:

1. GN Centrifugal Degasser

GN centrifugal degasser also called atmospheric degasser, it is especially used for compact room, the vented gas is especially used to collect the harmful gas.

2. GN 30 inch Decanter Centrifuge

Now the 30 inch rotating bowl centrifuge is the largest centrifuge that GN Solids manufactures. 30 inch rotating decanter centrifuges are mainly used for large capacity mud treating, such as the Tunneling Boring Machine working area.

3. GN Cuttings Transfer Pump

GN cutting transfer pump is especially designed to transfer high viscosity and large density drilling cuttings. As most of the drilling cuttings will get thick after stock in the mud pit for a long time, so transfer those cuttings into GN Shaker or Centrifuges should use GN cuttings transfer pump.

- Details

-

Published: 09 February 2017