GN Solids Control manufactures various shaker screens and provides shaker screens to more than sixty countries. With these years’ fast development, GN Solids Control has been getting to known by more and more shaker screens users.

GN Solids Control shaker screens are largely used by drilling contractors, now most of the world famous shaker screens can be replaced with GN shaker screens, such as Mongoose screens, Derrick 500 and Derrick 2000 shaker screens, Fluids System screens, NOV Venom screens etc. GN Shaker screens are largely needed and be purchased regularly by global customers. Now GN Solids Control manufactures more than 5000 pieces every month, the typical lead time for 500 pieces shaker screens is around 20 to 25 days.

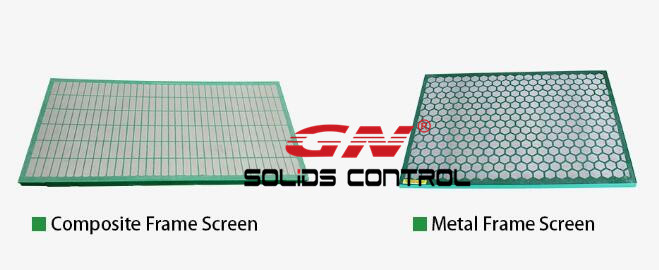

GN Solids Control shaker screens have already been proved the most cost effective shaker screens comply with API standard. GN Solids Control now manufactures two types of shaker screens: one is in metal frame and the other is on composite frame. Actually, the composite shaker screen’s frame is embedding with steel frame which are welded by robot. The outside part is made by plastic by mould. That composite frame is mixed with high quality fiber glass for higher temperature usage, also has a the excellent character of vibrating resistant.

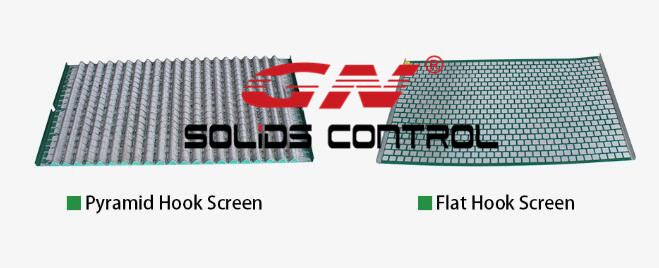

GN Solids Control provides shaker screens with rectangular weave, which formed by larger diameter wire (50% larger than the square weave wire) for excellent permeability under the same separating performance. The most important thing is GN rectangular weave last longer than the regular square weave screens.

GN Composite Shaker Screens can be stock for a long time without get rusty. While for the metal frame shaker screens, it can never compare the composite shaker screens which can last almost 5 years.

Now GN Houston warehouse has thousands of shaker screens stocking. They can be picked and delivered in a short period. Many companies keeps purchasing from GN Solids on the shaker screens. GN Solids Control shaker screens will always be your best alternate plan. If you’re tired of paying high price shaker screens, feel free come to us, even customized shaker screens can be made by GN Solids Control.

- Details

-

Published: 08 December 2016

GN Solids Control has been manufacturing shaker screens for many years. GN Solids Control shaker screens can be widely used to replace world famous shaker screens, such as shaker screens for Mongoose, Derrick, Brant (King Cobra or Venom), FSI and Elgin shaker screens. GN shaker screens are widely known due to the most effective feature.

GN Solids Control now manufactures over 5000 pieces shaker screens monthly. Most of the shaker screens are composite shaker screens. Before GN Solids Control were mainly provide metal frame shaker screens. GN Solids Control engineers have been upgraded the shaker screens manufacture process, so most of the shaker screens are composite material shaker screens.

If you compare the Composite Shaker Screens with GN Metal Frame Shaker Screens, you will find that GN composite shaker screens are very cost effective although the price is a little bit higher. The frame of GN composite shaker screens is welded by automatic robot, so the inside metal frame has a very good welding seam. And the outside frame is using high quality plastic. The composite shaker screens are made by using mould, so the shaker screens’ frame can be kept in a very good consistency even we manufacture over 5000 pieces every month.

Due to the special pretension technology, GN composite material shaker screens can be used for a longer time than the metal frame shaker screens. As most of competitors are using 2 layer cloth to manufacture the shaker screens for API no. below API 140. While GN Solids Control uses 3 layer wire mesh to manufacture shaker screens when the API no. is larger than API 60.

It’s obviously to know that GN metal frame shaker screens are a little bit heavier than the metal frame shaker screens. So when changing the screens after used for a while on the shaker, GN composite shaker screens are more convenient to change and clean.

The most important thing is GN composite shaker screens can be used 20~30% time longer than the metal frame shaker screens before broken in the same working condition.

- Details

-

Published: 02 December 2016

More Composite Shaker Screens Will Arrive At GN Houston Warehouse

As is known to all, GN Solids Control is famous for manufacturing a variety of shaker screens. GN shaker screens are mainly including all the popular shaker screens, such as replacement screens for Mi-Swaco Mongoose, Nov Brant, Nov VSM, Derrick 500 and Derrick 2000, FSI, Kemtron and some other shaker screens. Most of GN shaker screens are composite frame shaker screens, which is much better the metal frame screens.

With the increasing demands of GN shale shaker screens, GN Solids America LLC keeps thousands of shaker screens stocking in Houston warehouse, which is around 30,000 SF. Every month, GN Solids America LLC receives more shaker screens from its headquarters GN Solids Control.

Now GN Solids Control has two manufacturing plants near Beijing Airport, it’s only 40 km far away. While for these two manufacturing plant, it’s only 10 mins drive from each other. GN Solids Control has invested huge money to build the No.2 factory last year, and in this February GN Solids start to manufacture shaker screens the No.2 factory. With the opening of GN No. 2 factory, GN Solids Control is able to provide twice volume shaker screens. So customers can have GN shaker screens in a short period.

GN Houston warehouse now has over 1000 pieces shaker screens in stock. In the next several weeks, another 2 40ft containers will be delivered to GN Houston warehouse. Both of these 40ft containers are filled with composite shaker screens. GN Solids America LLC will be able to provide more replacement Mongoose shaker screens and replacement King Cobra shaker screens in the near future.

GN Solids America LLC has great interests to develop local distributors in USA, Canada and Mexico. For customers have interests to become GN shaker screen distributors, please feel free to connect with us. Free samples can be provided for testing.

- Details

-

Published: 17 November 2016

GN Solid Control just came back from the 2016 ADPIEC. The 2016 ADIPEC is one of the largest oil and gas conference and exhibitions in the world. This year GN Solids Control exhibited one decanter centrifuge and some shaker screens.

GN Solids Control has been working on designing and manufacturing the shaker screens for many years, until now GN Solids Control has sold its shaker screens to customers from over sixty countries and regions. GN Solids Control is able to manufacture more than five thousand pieces shaker screens every month. As GN just established the No. 2 factory to manufacture shaker screens, GN Solids Control will provided more and more shaker screens with a much better lead time.

The 2016 ADIPEC show is a very successful show, there are over thousands of attendees came to this show. GN Solids Control exhibited one set of decanter centrifuge (which is GNLW363 centrifuge with 14 inch rotating bowl) and some shaker screens. All of those products were arouse the great interests by many large drilling customers. GN Solids Control has already provided many decanter centrifuges to global clients. With the oil price is getting down, GN Solids Control become the first choice for many drilling customers as they want to cut cost but don’t want to just use cheap equipment. GN High Cost Effective equipment have been largely used by global drilling customers, and GN Solids has already become one of the top brand for solids and liquid separation.

GN Solids Control provides the best quality shaker screens, all of those screens can be used to replace screens like Derrick, Mongoose, FSI, Kemtron, King Cobra or Venom screens etc. GN OEM screens have been helping customers to cut cost largely. Now GN Solids Control manufactures shaker screen frames made from metal and composite material. GN composite frame screens can be used for more than 20% days longer than the metal frame. Many screens are stocking in GN Houston shaker screen warehouse, welcome to visit us and check with what API screens we have.

- Details

-

Published: 10 November 2016

As a well- known shaker screens manufacturer, GN Solids Control has manufactured thousands of shaker screens for American customers. GN Solids Control has been working on manufacturing shaker screens for many years, now many famous replacement shaker screens are manufactured. USA customers can have very cost-effective shaker screens from GN Houston office.

GN Solids Control manufactures two types shaker screens if we divided them into by the screen material: one is metal frame shake screens with the screen cloth, the other is composite frame (embed with metal frame) and screen cloth. The embedded metal frame inside the composite screens is welded by automatic welding machine.

Due to the manufacturing process of Composite Shaker Screens are different from Metal Frame Shaker Screens, GN composite shaker screens can be used for longer time while the effective working room is around 20% larger than the metal frame screens. And GN Solids Control designed and manufactured rectangular weave screens by using SS316L wire which life time is much longer than the square type screens. All those GN screens are manufactured conform to the API RP 13C standard.

GN composite shaker screens are made by using different molds, which guarantee the manufacturing consistency for large quantity order. And the pretension method that used on manufacturing GN composite shaker screens also improve the separating performance as the screen cloth is firmly glued on the screen frame.

GN Solids Control uses 3 layers of screen clothes for those screens above API 60, while most of other manufacturers are only using 3 layers above API 120.

Generally speaking, GN Composite Shaker Screens can be used around 300~700 hours, life time might be a little bit different when screens are separating various drill cuttings.

GN has sold many composite shaker screens in USA, Canada and Mexico. For customers have large need on shaker screens, GN Composite Shaker screens will always be the first choice. As the composite shaker screens can be stocked for a longer time without get rusty.

- Details

-

Published: 03 November 2016