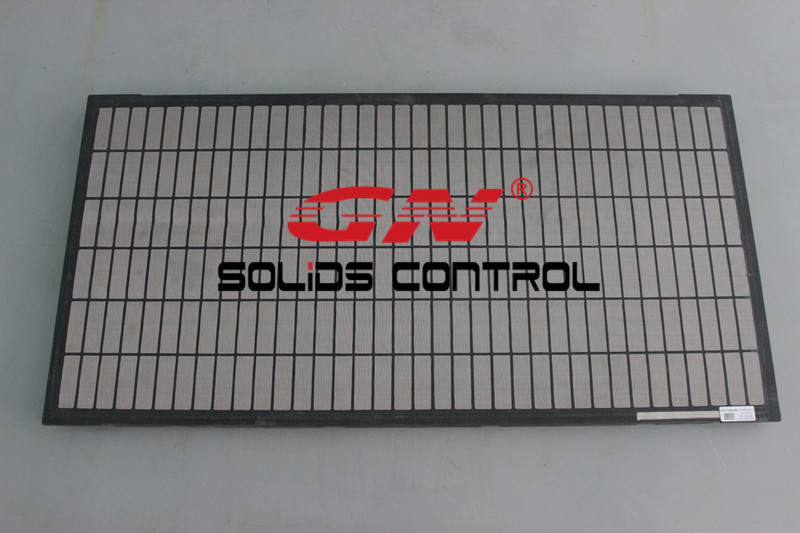

GN Solids Control has provided thousands of shaker screens to worldwide customers. Varieties of shaker screens are now manufactured by GN, such as screens for Mongoose, NOV King Cobra or Venom, Fluids System, Derrick etc. GN Solids Control now manufactures at least five thousands of shaker screens. Advanced molding machines and robots are used during the composite frame shaker screen manufacturing.

GN Solids Control would like to give sincere thanks to those customers who choose GN shaker screens and have been cooperating with GN for a long period. Now GN Solids Control would like to offer a large promotion policy for GN shaker screen users.

For every piece of shaker screens that you purchased, you will earn 1 point automatically. Once your accumulated to 1000 points, you could use it as a coupon to get discount when purchase GN Solids Control and Waste Management Equipment. Up to15,000 USD can be deducted from your purchase. The large promotion policy lasts for 2 years. For details, please feel free to connect with GN Solids America LLC via

This email address is being protected from spambots. You need JavaScript enabled to view it.

or +001-713-878-0880.

GN Solids Control has worked together with one USA Third Party to check GN shaker screens. From the recent test reports issued by this third party, all GN made shaker screens are conform to API RP 13C standard. As we all know, API NO. is one of the most scientific ways to class shaker screens key parameters such as cut point, conductance. The former mesh name method sometimes getting harder for customers to choose which one suit them better due to different screen manufacturers are using different wire cloth manufacturer which result the wire diameters are not the same.

GN Solids Control America will keep working with this third party to test GN made shaker screens for quality control. And GN Solids will also test shaker screens by themselves. Now GN Solids America LLC stocks thousands of shaker screens in Houston warehouse, feel free to connect with us if you’re tired of using expensive OEM screens and want to the find a better price but still the OEM quality.

- Details

-

Published: 17 August 2017

GN Solids Control is a shaker screens manufacturer located in China near Beijing. Every month, GN Solids Control delivers more than 5,000 pieces shaker screens to global customers. GN Shaker screens include metal frame types screens and composite frame shaker screens. Almost all the GN customers prefer to use GN composite frame shaker screens after they compared Composite Frame Screens with Metal frame Screens.

To be proudly as one of the largest shaker screen manufacturer, GN Solids Control products have been largely used in over 72 countries. With the opening of GN Solids America LLC (in Houston, TX) and GN Solids Russia (Moscow, Russia), GN Solids Control shaker screens is getting to known by more and more shaker screen users.

GN Solids Control provides customized shaker screens which mean: customize size and customized package. We understand that some of the shaker screen users are not only using the global famous shaker screens, such as Mi-Swaco Mongoose, NOV King Cobra, NOV Venom, Fluid Systems screens, Derrick shaker screens. GN Solids Control is able to manufacture customized shaker screen based on the screen dimension you provided. Sometimes, GN customers don’t want to know they buy shaker screens from us, so we can provide customized package service with customers’ logo.

This is a great chance for all shaker screen manufacturers as the oil price is pretty low. All the shaker screen users are looking for the most cost-effective products. Just recently, we also have heard a great from our friends; they told us that Kuwait Oil Company (short for KOC) has released a tender for eighty-five rigs. Seems those drilling rigs will be provided by some in Italy & Romania drilling rig manufacturers. It says there are total 4 tenders, it’s mainly includes the following rigs: Twenty five Drilling Rigs of 3000 HP; Seven Drilling Rigs of 1500 HP; Twenty Seven Drilling Rigs of 1000 or 750 HP; Twenty Six Work over Rigs.

- Details

-

Published: 08 August 2017

GN Solids Control is the No.1 China shaker screen manufacturer. Every year, thousands of shaker screens are manufactured by GN Solids Control. GN Solids Control shaker screens are using in more than seventy countries such as USA, Canada, Mexico, Argentina, Chile, Peru, Venezuela, Columbia, England and Russia as well as some other countries.

GN Solids Control No. 2 factory is located in Langfang, China, which is pretty close to GN Solids Control headquarters. Both GN Solids headquarters and GN No.2 factory are close to Beijing International Airport.

With these years fast development, GN Solids Control is getting to known by more and more oil and gas professionals. As one the wearable parts, GN shaker screens are pretty popular.

GN Solids Control invite Intertek USA to test GN Composite Frame Shaker screens, and they all conform to API RP 13C standard based on the report issued by Intertek.

Until now, GN Solids is the only Chinese shaker screen manufactuer who has the Third Party Report. From the test that provided by Interterk, you will see all GN made screens confrom to API RP 13C standard. There are many USA companies are using GN shaker screens, and they actually compared our screens with many USA made screens (such as original Mi-Swaco Mongoose screens or screens made by Screen Logostic, Continental etc), feedbacks we have are GN screens have better separating performance and longer life.

The easiest and most simple way is compare our screens with your current screens. Put them on one drilling rig, paralled shakers, it's always worth to try if you could find the most cost-effective screen manufacturers.

There is an old China provoke: ‘Seeing is believing’. GN Solids Control welcomes any company to visit us. Samples can be provided if customers have regular demands. Please feel free to connect with us.

- Details

-

Published: 29 July 2017

GN Solids Control is a shaker screen manufacturer from China. GN Solids Control manufacturing plant is located in Langfang, China which is only 40km far away from Beijing International Airport. GN Solids Control is proud to be the No.1 shake screen manufacturer.

GN Solids Control has very strict rules and quality control standards when manufacture different kind of shake screens. Now GN Solids Control also had a Third Party which is Interk USA to test GN shaker screens. Based on the reports issued by Interk, all those screens manufactured by GN shaker screens conform to API RP 13 C standard.

GN Solids shake screens now includes the following replacement screens like Mi-Swaco Mongoose, NOV King Cobra/ Venom, Derrick 500 and Derrick 2000, NOV VSM 300 screens etc. Some customized screens can be also manufactured by GN Solids if customers can provide screen size or pictures.

GN Solids Control opened the No.2 shaker screens manufacturing plant in this February. GN Solids Control now manufactures over 5000 pieces shaker screens every month. GN Solids Control has delivered shaker screens to over 72 countries or regions.

GN Solids Control also built the Houston branch company GN Solids America LLC in 2013. GN Solids America LLC is the first China manufacturer that built USA branch company in Houston, TX. GN Solids America LLC owned a large warehouse which can stock over 5000 pieces shaker screens. For customers have immediate needs, GN Solids America LLC is able to deliver shaker screens to customers work sites in a pretty short period.

GN Solids Control is especially good at manufacturing Composite Frame Shaker screens. GN Solids Control is using robot to weld the shaker frame in order to keep a good consistency. During the shaker screen heating process, GN Solids Control is using pretension way so all the wire cloth can be pressed flatly on the shaker frame.

- Details

-

Published: 23 July 2017

GN Solids Control is a famous shaker screen manufacturer, every month GN Solids Control is able to manufacture more than 5000 pieces shaker screens, GN shaker screens can be widely used to replace screens like Derrick 500 or 2000, Mi-Swaco Mongoose, NOV King Cobra/ Cobra, NOV VSM 300, Fluid System etc.

GN Solids Control shaker screens have been sold to more than 70 countries, like USA, Canada, Mexico, Chile, Brazil, Argentina, Venezuela, Peru etc. Some other regions such as Africa, Middle East, Europe or Asia are also widely using GN shaker screens.

With more and more demands on shaker screens, GN Solids Control now is looking for distributors globally. GN Solids Control has one branch company in USA, which are mainly used to stock thousands of shaker screens and many solids control equipment. As GN Solids America LLC have many regular orders every month, so GN Solids usually keeps at least 3000 pcs screens in Houston warehouse. Whenever customers have the needs for shaker screens in North America or South America, GN Solids Control is able to provide the shaker screens in a pretty short time.

In order to serve customers better, GN Solids America LLC has large interests to find shaker screens distributors in Latin America. GN Solids Control has provided shaker screens in Latin America for many years, there is an increasing demands for shaker screens with the oil price going up.

Welcome to join us, if you have rich experience in oil and gas area and ha ve wide relation with many drilling companies, we would like to invite you to join us and become GN partner. GN Solids Control now mainly manufactures composite frame shaker screens, which are more cost-effective than the traditional metal frame shaker screens. Metal frame screens are covered with composite material, which makes it lighter than the former metal screens. Please feel free to connect with us for any questions you have, connect email:

This email address is being protected from spambots. You need JavaScript enabled to view it.

ve wide relation with many drilling companies, we would like to invite you to join us and become GN partner. GN Solids Control now mainly manufactures composite frame shaker screens, which are more cost-effective than the traditional metal frame shaker screens. Metal frame screens are covered with composite material, which makes it lighter than the former metal screens. Please feel free to connect with us for any questions you have, connect email:

This email address is being protected from spambots. You need JavaScript enabled to view it.

- Details

-

Published: 15 July 2017