GN Solids Control is a top shale shaker manufacturer, varieties of shaker screens have been manufactured by GN Solids Control every day. With more and more shaker screens are used by world customers, GN Solids Control has won a very good reputation as the most cost-effective shaker screens manufacturer.

GN shale shaker screens have already been by widely used in over 70 countries until now, due to there are more than 900 drilling rigs in North America, GN Solids Control has also known by GN Solids America LLC which is the branch company of GN Solids Control. GN Solids America LLC has a large warehouse in Houston, thousands of shaker screens can be stocked here along with some shale shakers, decanter centrifuges and cuttings dryers etc.

GN Solids America LLC keeps selling shaker screens in North America. There are many old customers keep purchasing from GN Solids regularly. GN Solids Control delivers at least one 40Ft container from China to Houston every month. One 40ft container can be filled with almost 1500 pcs shaker screens. Plus those several thousands of shaker screens stocking in Houston warehouse, so GN Solids America LLC can always have those best-selling shaker screens for customers and can be delivered to customers’ work sites pretty fast.

GN Solids Control mainly keeps stock of replacement screens such as Mongoose, Venom/ King Cobra, Fluid System or Derrick screens in Houston. Most of the screens are composite frame screens which are very popular than the traditional metal frame shaker screens.

GN Composite Frame screens are much lighter than metal frame screens. High quality plastic materials are covering metal frame screens in order to have a good rigidity. GN Houston warehouse now are filled with thousands of shaker screens, if you need any screens, please feel free to send your inquiries to

This email address is being protected from spambots. You need JavaScript enabled to view it.

or you may call 713-320-3868 for any screens needs.

- Details

-

Published: 01 July 2017

GN Solids Control just provided one whole set Dewatering System to Korea. Dewatering unit is mainly used to separate out finer solids in the slurry, no matter its oil base slurry, water base slurry or synthetic base slurry.

As one of the leading decanter centrifuge designer and manufacturer, GN Solids Control manufactures over 350 sets decanter centrifuges every year. GN Solids Control has providing decanter centrifuges to customers from over 70 countries. Due to GN Solids Control only targeted to provide decanter centrifuges to the top-tier market, GN Solids Control always choose the best quality components in order to have excellent working performance and long using life. Such as the two main bearings of GN rotating bowl, GN Solids Control is using genuine SKF bearing. While for most of the electrical components, GN Solids Control also only uses top brands such as ABB or Schneider.

This GN Dewatering Unit is including the following two equipment:

1. GN Decanter Centrifuge

One set of GN centrifuge is fixed on the top of GN made telescopic skid. The centrifuge can be lifted to a higher level when working so the discharged solids can be collected conveniently. By taking advantage of the gravity difference, solids and liquid are rotating at a higher speed along with the centrifuge rotating bowl. GN screw conveyor inside the centrifuge helps to push those solids out of the collecting box.

Here GN Solids Control assembles one VFD control box for this centrifuge, all those parameters such as rotating speed, differential speed etc can be changed easily. Based on the using environment, GN Solids Control provides ATEX or IEC EX explosion-proof standard for choose.

2. GN Chemical Dosing Unit

GN chemical dosing unit helps to remove finer solids by adding chemicals into the drilling slurry before feeding into GN decanter centrifuge. GN Solids Control provides test lab in order to find the most suitable chemical. In order to more conveniently, GN Solids Control put the chemical dosing unit in a standard container.

- Details

-

Published: 21 June 2017

GN Solids Control is one of the most famous shake screens manufacturers. Shaker screens are largely used on shale shaker, which is one pretty common used separation equipment to eliminate liquid from various slurries.

Shaker screen is some pre-tensioned wire clothes that glued on the top of screen panel. In order to have different cut point or conductance, GN shaker screens are composed by different size wire cloth. As different shaker screens manufactures may use different size wire, so the former Mesh No. to classy shaker screens are not preciously. Now more and more shaker screens manufacturers are using API no. GN Solids Control has a Third Party to test screen parameters in order to conform to the API RP 13C standard.

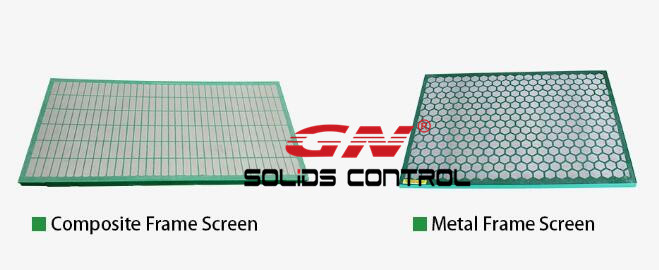

Generally speaking, composite frame shaker screens are better than the metal frame screens. There are some customers who are not familiar with shaker screens can not tell the difference, so today we will compare these two type screens so you will know which one is better.

1. Weight:

Composite frame shaker screens are metal frame covered with plastic. In order to have the same size, we need to user thicker metal which result the screen is heavier.

Due to shaker screens are wearable parts, workers need to change them after use for 3 or 5 days. GN shakers screens help customers to cut huge cost as GN screens do last longer. And only one worker is totally enough to clean and change shaker screens as GN Solids uses composite frame screens which embedded with metal frame.

2. Effective using room:

When we try to glue wire cloth on the top of shaker screen, it’s easier to glue with plastic compared to metal. Just in case the screen cloth does not fall off from metal frame easily, we need to use more horizontal and vertical supporting frame, so the composite frame screens have larger effective using room.

3. Separating performance:

Due to the manufacturing process is a little bit different, composite frame shaker screens are using much better pre-tensioned technology. This is pretty important for long time separating. And GN shaker screens are using 3 layers of wire cloth for all those composite screens above API 60.

- Details

-

Published: 07 June 2017

As a leading manufacturer on solids control equipment and waste management systems, GN Solids Control has been delivered its products to over 70 countries and regions. GN Solids America LLC is one branch company of GN Solids Control. With the fast development of GN Solids America LLC, now GN Solids has more and more inquires every month, we are willing to invite some partners to join us and built a win-win cooperation.

GN Solids Control is especially good at manufacturing all the solids and liquid separation equipment. In GN Houston warehouse, there are many shale shakers, desanders, desilters, mud cleaners and decanter centrifuges as well as cuttings dryers in stock. GN Solids Control products have been largely proved to working in various industries. GN Solids Control focus on oil and gas area, but more and more industries are using GN Solids Control equipment.

With these years development, GN Solids Control has made large progress:

1. GN Solids Control is Leading Manufacturer in China;

2. GN Solids Control is the first API certified manufacturer on solids control and waste management in China;

3. GN Solids America LLC is first Solids Control company that built in USA from China.

4. GN Solids Control has various certificates like ISO, HSE etc. Also certified by DNV CE, Russia TP & TC.

5. GN Solids Control has exported to over 74 countries or regions.

There are many glorious history stilling writing by GN employees. GN Solids Control is devoted to be the world top one solids control and waste management manufacturer. Now GN Solids Control is willing to invite some partners to join us and expand business in USA, Canada and Mexico. GN Solids Control will provide the most cost-effective equipment and the best after sales service. GN Solids Control is pretty open to discuss on various cooperation.

- Details

-

Published: 01 June 2017

Are you looking for the most cost- effective shake screens? Are you want to have some screens in s short time? Then you need to connect with GN Solids America LLC for shaker screens.

GN Solids Control is a leading manufacture on shaker screens, over 5000 pieces of screens are manufactured. Now GN Solids Control manufacture all the replacement screens which can be used one Mi-Swaco shaker , Derrick Shaker (500 and 2000), Fluid System shaker, NOV Brant Shaker etc. GN replacement screens are widely used in over 74 countries and regions, more and more shaker users are coming to GN to purchase shaker screens. And GN Solids Control also provides customized logo and API tag for various shaker manufacturers.

With the opening of GN Solids America LLC, more and more local customers from North America are getting to know GN shake screens. Now GN Solids Control has more than 3000 pieces shaker screens are stocking in Houston warehouse. Basically, GN Solids America LLC keeps replacement Mi-Swaco Shaker screens, replacement King Cobra/ Venom screens, replacement 285P (Nov screens), replacement FSI screens as well as replacement Derrick screens stocking in Houston.

Whenever customers have immediate demands, shaker screens can be packaged and delivered in a really short period. Shaker screens are wearable parts, you use them and you throw away. We have to admit that the manufacturing cost is pretty high in USA, while if we made in China, we can help customers save a lot. For the typical drilling rigs that uses 4 sets of Mi-Swaco shakers, screens need to be changed every 3~5 days, which is around 120 pcs shaker screens. If customers use GN replacement composite frame screens, customers can save at least 100 usd for each piece, which is 12,000 usd/ month and 144,000 usd/year. GN Solids Control has widely tested GN made composite screens, for the same drilling mud, GN screens are even performing better.

Please call 713-878-0880 for the most cost-effective shaker screens.

- Details

-

Published: 25 May 2017