With the fast growth of GN Solids America LLC, GN Solids now has a large Houston warehouse that stock thousands of shaker screens in TX, USA. GN Solids Control shake screens have already been widely proved to work fantastic in different worldwide drilling sites.

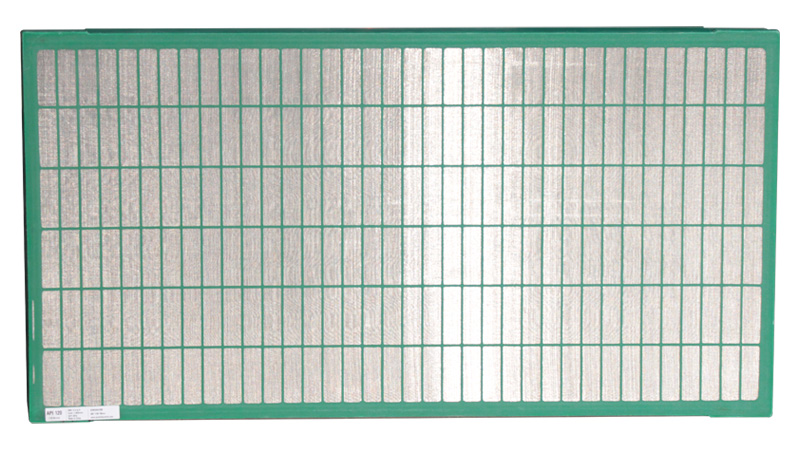

GN Solids Control manufactures different types of shake screens that basically cover all those popular size shaker screens. GN Solids shaker screens have OEM screen quality but without OEM screen price. What GN Solids Control trying to provide is the most cost-effective shaker screens option for OEM screens.

Now GN Solids Control shaker screen product line includes replacement screens for Mongoose, replacement screens for VSM 300, replacement screens for King Cobra/ Cobra, replacement screens for Venom and replacement screens for B380 as well as replacement screens for Derrick 500 and 2000 etc.

GN Houston warehouse built a large stock for all those above mentioned shaker screens, which over different API no. from API 10 to API 325. In fact, GN Solids Control hired one USA third party to test GN shake screens cut point, NBA etc so it can comply with API RP 13C standard strictly.

GN shaker screens are using 3 layers for those API no. above API 60. We are not just wanted to cut our cost by using less raw materials or use second-tier shaker screens. GN Solids Control is using same brand wire cloth vendor as Derrick and Mi-Swaco in order to guarantee the quality.

GN Solids Control has its own inject molding machine that can manufacture its own composite frames. GN Solids control shaker screen product line also uses automatic robot for welding in order to keep the metal frame screen quality consistent.

If you need any shaker screens, please feel free to contact with GN Solids America Houston office, our sales rep. will be glad to help you find the perfect shaker screens. Even if you are looking for some customized size shaker screens, we are also glad to help with.

- Details

-

Published: 06 September 2018

As a large solids control and waste management equipment manufacturer, GN Solids Control has providing shaker screens to customers from over seventy countries. It’s well known that GN shaker screens also means the most cost-effective shaker screens in the world. Thousands of drilling contractors are using GN shaker screens. GN Solids manufactures different types of shaker screens to cover those most used shaker screens. Now GN Houston warehouse is stocking 5,000 ~ 6,000 pcs screens, ready to go.

Besides GN shaker screens, GN Solids Control also manufactures some other solids control equipment like decanter centrifuge for a long time. GN decanter centrifuges are mainly used to eliminate finer solids less than 2mm from different sludge. GN Solids Centrifuge includes 9inch, 14inch, 18inch and 20inch as well as 30inch, which are classified by centrifuge rotating bowl size.

These 2 sets centrifuges are 14inch centrifuges that will be provided to a USA drilling company. They will use these centrifuges for barite recovery: the first 14inch centrifuge set at middle rotating speed and the second 14inch one set at high speed.

2 centrifuges play the function of 2 phase separation: the first one separate out most of those solids by volume while the second separate solids by mass. Or we can say the second centrifuge is mainly used to eliminate finer solids. Typically, GN Solids Control decanter centrifuges are used to separate out solids larger than 2~5microns.

GN Solids Centrifuge rotating bowl is made by centrifugal casting and the inside impeller is protected by some tungsten carbide tiles fixed by bolts. GN Solids Control only uses top brands electrical control components such as in the VFD we are using ABB or Siemens brand. For the mechanical part like the 2 main bearings, GN Solids Control uses SKF bearing.

GN Solids Houston warehouse also has several decanter centrifuge in stock, VFD control with explosion-proof. All the spare parts or wearable parts are accessible from Houston as well.

- Details

-

Published: 01 September 2018

GN Solids Control is a top shaker screen manufacturer. GN Shaker Screen product line cover most of those famous shaker screens sizes besides GN own made shaker screens. GN shaker screens type now includes replacement screens for Mi-Swaco Mongoose, Derrick 500 and 2000 (includes flat panel and pyramid), NOV King Cobra/ Cobra/ Venom/ VSM etc.

Due to GN Solids Control also manufacture its own brands shakers, GN shaker screens can be also used on GN different types of screens.

With the increase needs of shaker screens and more and more active drilling rigs working, GN Solids America LLC is also stocking more and more shaker screens in Houston warehouse. It’s known to all that all shaker screens imported to USA are charged by 25% Tariff since July, 2018, all shaker screens manufacturers are affected by this policy includes GN. But GN Solids is willing to split part of the cost with our partners and face this special period. Actually, for the other shaker screen manufacturers, their manufacturing cost also increased due to lots of raw materials are imported from China includes steel to manufacture the screen frame and wire cloth.

Anyway, GN Solids America LLC keeps the record of shipping 1 or 2 containers from China to Houston every month. Plus those 5000 ~ 6000 pcs stocking in Houston warehouse, GN Solids Control is able to keep these screens in good turnaround.

GN Solids Control also provides patent shakers and shaker screens to protect our partners’ shaker screens business. As shake screens are wearable parts, they need to be changed every 7~15days in order to keep the drilling mud in good condition.

GN Solids Control are using in over 72 countries, and widely acknowledged by global customers. GN Solids Control shaker screens are using the most new technology to manufacture composite frame shaker screens which are last longer also separate better than traditional metal frame ones.

- Details

-

Published: 25 August 2018

GN Solids Control provided multiple sets of poor boy degassers for a Egypt customer weeks ago. It’s been a long while that GN hasn’t provided multiple sets poor boy degassers since the oil price was around 30~40 usd/barrel. We are positively to see this is a good sign that more and more drilling rigs will be back to work and expecting there will be larger needs on the solids control and drilling waste management treating equipment.

GN Solids Control is mainly focused on manufacture the most cost-effective solids control and waste management equipment. It is well known that GN Solids product line includes shale shaker, de-sander, mud cleaner, de-silter, decanter centrifuge and cuttings dryer etc. GN Solids Control also manufactures thousands of shaker screens every month.

Based on former years manufacturing history, GN Solids Control manufacturing plant now can manufacture 300~500 sets shale shakers, 300 sets decanter centrifuges, 150 sets cuttings dryers and hundreds sets of whole solids control mud systems and drilling waste management systems.

GN Solids poor boy degasser is one system that can eliminate air from drilling mud. It is usually connected with high drilling pipes from mud pumps. Large air can be eliminated from the drilling mud, especially those hazardous airs. One flare igniter is also used to connect with the poor boy degasser so they can be burned in a faraway place.

Besides poor boy degasser, GN Solids Control also manufactures vacuum degasser and centrifugal degasser. GN Vacuum Degasser and GN Centrifugal Degasser play the same function which is to eliminate finer bubble in the drilling mud before feeding into desander cyclones or desilter cyclones.

Now all those 4 sets poor by degassers have been finished manufacturing, will be shipped to Egypt soon.

As a branch company of GN Solids control, GN Solids America LLC now has many solids control and waste management equipment stocking in Houston. Welcome to visit us and check our storage.

- Details

-

Published: 12 August 2018

GN Solids Control is a turnkey solution provider for oil sludge that comes from Oil Tank bottom, refinery plant, drilling rig site etc. GN Oil Sludge Treating System is especially good at treating large solids content, high density and high viscosity oil sludge.

Last week, GN Solids Control finished the manufacturing of one whole set oil sludge treating system for a European client. GN Oil Sludge Treating Systems include the following main components:

1. Feeding Pump

Usually a GN vacuum pump can be used as a feeding pump. GN vacuum pump is especially designed to transfer oil sludge to a long distance area. Solids less than 75mm can be transferred by this vacuum pump. GN Solids Control has 3 different models: 40m3/h, 20m3/h and 10m3/h.

2. Pre-mixing & Heating Tank

Pre-mixing & Heating tank is used to mix and heat the oil sludge. Chemicals will be added in order to have a better dilute performance. Along the tank wall it's fixed with heating pipes which are feeding by hot water or steam.

3. Coarse Shaker

Coarse shaker is the first treating equipment that can actually separate some particular sizes from the slurry. Depend on the API no. of the shaker screens, different size solids can be separated out. GN Solids is one the largest shaker screens manufacturers. Besides those shaker screens used on GN shakers, GN Solids Control also provides replacement screens for the other common used screens.

4. 2 Phase Decanter Centrifuge

GN 2 phase decanter centrifuge separate oil solids from liquid. Solids larger than 2~5 microns can be separated out. Here the centrifuge is feeding by one screw pump, slurry discharged from the shaker is mixed and feed to this 2 phase centrifuge.

5. 3 Phase Disc-Centrifuge

GN Disc-Centrifuge can fulfill of separate solids, liquid and water. Liquid treated after 2 phase centrifuge falls into 3 phase Disc-centrifuge directly.

6. Chemical Dosing Unit

By using several chemical tanks, we can feed chemicals into the mixing tank and decanter centrifuge.

- Details

-

Published: 05 August 2018