With the fast growth of GN Solids America LLC, GN Solids now has a large Houston warehouse that stock thousands of shaker screens in TX, USA. GN Solids Control shake screens have already been widely proved to work fantastic in different worldwide drilling sites.

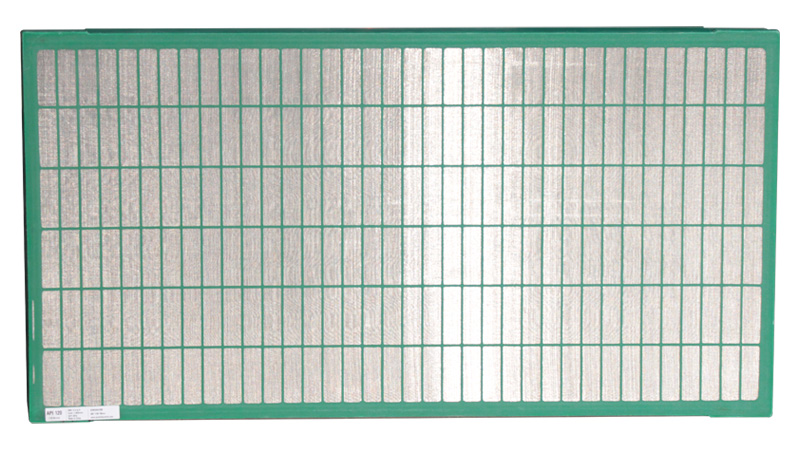

GN Solids Control manufactures different types of shake screens that basically cover all those popular size shaker screens. GN Solids shaker screens have OEM screen quality but without OEM screen price. What GN Solids Control trying to provide is the most cost-effective shaker screens option for OEM screens.

Now GN Solids Control shaker screen product line includes replacement screens for Mongoose, replacement screens for VSM 300, replacement screens for King Cobra/ Cobra, replacement screens for Venom and replacement screens for B380 as well as replacement screens for Derrick 500 and 2000 etc.

GN Houston warehouse built a large stock for all those above mentioned shaker screens, which over different API no. from API 10 to API 325. In fact, GN Solids Control hired one USA third party to test GN shake screens cut point, NBA etc so it can comply with API RP 13C standard strictly.

GN shaker screens are using 3 layers for those API no. above API 60. We are not just wanted to cut our cost by using less raw materials or use second-tier shaker screens. GN Solids Control is using same brand wire cloth vendor as Derrick and Mi-Swaco in order to guarantee the quality.

GN Solids Control has its own inject molding machine that can manufacture its own composite frames. GN Solids control shaker screen product line also uses automatic robot for welding in order to keep the metal frame screen quality consistent.

If you need any shaker screens, please feel free to contact with GN Solids America Houston office, our sales rep. will be glad to help you find the perfect shaker screens. Even if you are looking for some customized size shaker screens, we are also glad to help with.

- Details

-

Published: 06 September 2018