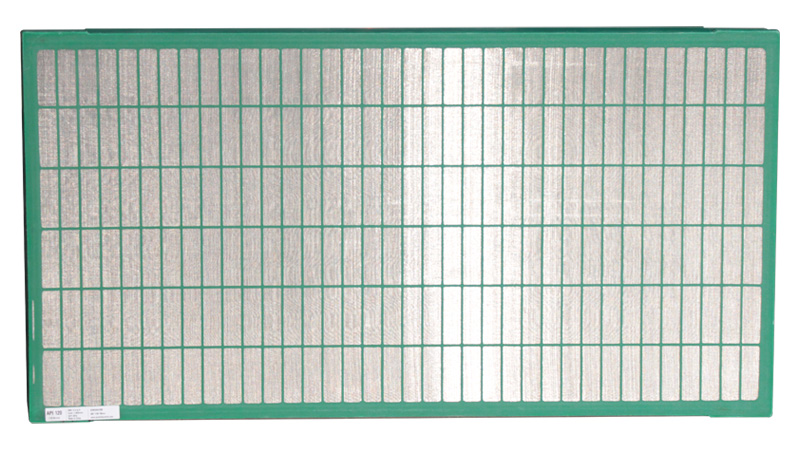

It’s known that GN Solids Control manufactures different types of shaker screens. GN Solids Control Metal Frame Shaker Screens and Composite Frame Screens are both widely accepted by global customers. GN Solids Control made composite frame shaker screens are more cost effective.

GN shaker screens are GN made wearable parts. Beside GN screens, GN Solids Control also provides turnkey solutions for solids and liquid separation demands, such as TBM slurry treating, Oil Cuttings treating, Dredging Slurry Treating etc. GN Solids Control has provided some TBM slurry treating systems. Here is one TBM slurry treating system that we provided to customer months ago, main components are following shows:

1. Hi-Cap Shaker Tank:

Shaker tank is fixed with 3 sets GN Hi-Cap shaker. A box type mud distributor is used to connect these 3 sets tank together.

2x 75kw(100HP) Centrifugal pumps are fixed on the tank bottom to feed Large Desander.

2. Large Desander Tank:

Fixed with 2 sets GN703 shakers, each one fixed with 2 sets 20inch cyclones.

2x 75kw(100HP) Centrifugal pumps are fixed on the tank bottom to feed Small Desander.

3. Small Desander Tank:

Fixed with 2 sets GN703 shakers, each one fixed with 3 sets 10inch cyclones.

2x 75kw(100HP) Centrifugal pumps are fixed on the tank bottom to feed Desilter.

4. Desilter Tank:

Fixed with 2 sets GN703 shakers, each one fixed with 20 sets 4inch cyclones. Cyclones are fixed in a circle to save working room.

5. Centrifuge Skid:

2 centrifuges in total, each one is fixed on skid for lifting. Here GN Solids Control provides 2 sets 22inch bowl size decanter centrifuges. GN Solids Control also provides larger bowl centrifuge upto 30inch.

All the above tanks or skids are around on 6m length mud tank. Tank is also fixed with mud agitator to keep slurry from sediment.

- Details

-

Published: 19 October 2018

GN Solids Control is a top solids and liquid separation equipment manufacturer. GN Solids Control equipment covers most common used treating equipment like shale shaker, desander, desilter, mud cleaner and decanter centrifuge etc. Some auxiliary parts like vacuum pump, screw pump, centrifugal pump, mud agitator, screw conveyor can be also provided by GN.

Besides those above mentioned standard treating equipment, GN Solids Control also provides customized treating systems, like drilling waste management systems, hydrocvac slurry treating systems, mining solids removal treating systems etc.

GN Solids Control has provided equipment to 70+ countries and regions, over nearly 70% sales is outside of China market. Today we would like to share one project that we did in Asia several weeks ago. Here is the equipment that GN provided:

1. 6 Sets GN Vacuum Pump

GN Solids Control manufactures variety of pumps includes centrifugal pump, submersible pump, screw pump as well as vacuum pump. GN Vacuum Pump was first designed to help to suck those drill cuttings from a mud pit due to those slurry usually stick together and can not be pumped by the regular pumps.

GN vacuum pump can suck the slurry that contains 100% solids (particles less than 70mm), basically all the slurry as long as they can be moved will be able transferred by GN vacuum pump. Max. transfer distance can reach to 1000m. The good point is there are no mechanical transmission parts in the pump shell, so we don’t need to worry about the weariness after use for a while. GN Solids Control offers 3 different pumps for customer to choose which will need different air compressor for sure.

2. 30 sets GN Mud Agitator

GN Solids Control also provides 30 sets mud agitators to this Asian customer. Mud agitators are commonly used to keep slurry from sediment. Depend on the mud tank height, GN Solids Control provides single impeller and double impellers model.

- Details

-

Published: 10 October 2018

GN Solids Control just delivered 6 sets ViST units for a Russian customer. GN ViST is a newly developed product that is equipped to use with GN shale shaker. ViST is short for Vacuum Screen Technology. It helps to recover more drilling fluids and get dryer solids.

As one of the largest GN market, GN Solids Control has been providing a large quantity of solids control equipment as well as drilling waste management systems. Every year, GN Solids Control engineers provide some newly developed equipment to meet the changing demands of global customers. This ViST unit is developed to help customer treat drilling fluids in a most cost-effective way.

We all know that GN Solids Control manufactures the best quality shaker screens as well. GN shakers are all using GN made screens. Besides GN size screens, GN Solids Control also provides different types of common used shaker screens, such as replacement screens for Mongoose, Venom/ King Cobra, FSI, VSM300 etc. GN shaker screens are separating large solids by using the large G force of two vibration motors (either USA Martin or Italy OLI brand).

GN ViST is a new technology, the catch pan is fixed under the bottom of the last piece shaker screens or at the discharge port of the shaker. Typically, a GN ViST unit includes a vaccum unit that connected with 3 or 4 catch pans. An air compressor is also need to provide the suck force. Depend on the shaker screen size, GN ViST unit can be set to control on and off working time. Recycled drilling fluids is collected in a small tank, pipes discharge port can be set at either end of the shaker.

These GN Solids Control 6 sets ViST units will be shipped to Russia. GN Solids Control also provides some sets that using in offshore area.

- Details

-

Published: 30 September 2018

GN Solids Control is a leading manufacturer that devoted to provide the best and most cost effective solutions for global solids and liquid separation customers. More and more GN solids control and waste treating equipment are getting to known by global customers.

Every year, GN Solids Control engineers provide some newly developed equipment or at least upgrade the former version GN equipment by using new technology and based on customers’ feedbacks.

Today, we would like to introduce GN ViST technology. GN ViST unit is one newly developed equipment that can be used on shale shaker. It can help shale shaker to recover more drilling fluids and get dryer drill cuttings. GN ViST unit is including: vacuum unit, catch pan and connecting pipes.

There are 2 typical way to fix GN ViST Unit:

1. Fix the catch pan underneath the first piece shaker screen.

2. Fix the catch pan in the right front of the first piece shaker (also called the shaker discharged port).

An air compressor will be used to connect with GN ViST unit to provide air suction source. Depend on how many shale shakers are connected with GN ViST unit, it will need different air compressors.

GN ViST unit is suitable for OBM, WBM and SBM. It can help to recover 2000 to 3000L drilling fluids every day. The air controlled system can be set running every seconds so the it will work continuously.

GN Solids Control now provide this ViST unit as an optional if customer purchase GN shale shaker. As GN Solids Control provides different sizes shaker screens, it will be more be more convenient and accurate if fix on GN shale shaker directly. However, if customer is using not GN made shakers, GN Solids Control can also help customer to provide a suitable ViST unit as long as customers can provide several key factors.

- Details

-

Published: 22 September 2018

With the fast growth of GN Solids America LLC, GN Solids now has a large Houston warehouse that stock thousands of shaker screens in TX, USA. GN Solids Control shake screens have already been widely proved to work fantastic in different worldwide drilling sites.

GN Solids Control manufactures different types of shake screens that basically cover all those popular size shaker screens. GN Solids shaker screens have OEM screen quality but without OEM screen price. What GN Solids Control trying to provide is the most cost-effective shaker screens option for OEM screens.

Now GN Solids Control shaker screen product line includes replacement screens for Mongoose, replacement screens for VSM 300, replacement screens for King Cobra/ Cobra, replacement screens for Venom and replacement screens for B380 as well as replacement screens for Derrick 500 and 2000 etc.

GN Houston warehouse built a large stock for all those above mentioned shaker screens, which over different API no. from API 10 to API 325. In fact, GN Solids Control hired one USA third party to test GN shake screens cut point, NBA etc so it can comply with API RP 13C standard strictly.

GN shaker screens are using 3 layers for those API no. above API 60. We are not just wanted to cut our cost by using less raw materials or use second-tier shaker screens. GN Solids Control is using same brand wire cloth vendor as Derrick and Mi-Swaco in order to guarantee the quality.

GN Solids Control has its own inject molding machine that can manufacture its own composite frames. GN Solids control shaker screen product line also uses automatic robot for welding in order to keep the metal frame screen quality consistent.

If you need any shaker screens, please feel free to contact with GN Solids America Houston office, our sales rep. will be glad to help you find the perfect shaker screens. Even if you are looking for some customized size shaker screens, we are also glad to help with.

- Details

-

Published: 06 September 2018