GN Solids America was opened in 2014. With the great help from GN Solids Control, GN Solids America LLC has been enjoying the fast growth in USA. GN Solids America is the branch company of GN Solids Control.

GN Solids Control pays great attention to USA market. North America and South America market is one of the largest markets that use solids control and waste management equipment. As one of the leading solids control and waste management system manufacturers, GN Solids America LLC has a very close relationship with most of those drilling rigs contractors and oil and gas service companies. Many trading companies are also promoting GN Solids Control products. Now GN product line includes shaker shakers, decanter centrifuges, cuttings dryers, mud cleaners and various feeding pumps. GN Solids Control also manufactures shaker screens to replace most of those famous brands such as Mi-Swaco, NOV and Derrick etc. GN Solids Shaker screens are largely using in North America and South America. Many compare experiment in customers’ drilling rig sites have been operated and GN Solids Control shaker screens always received positive feedbacks, sometimes, GN made shaker screens are even better than OEM screens.

With the large warehouse in Houston, TX, GN Solids America now stocks thousands of shaker screens in Houston. GN Solids Control also has some sets decanter centrifuges as well as mud cleaners in Houston warehouse. In order to provide the best after sales service, GN Solids Control keeps those spare parts for shakers and decanter centrifuges in Houston. GN engineers are also available and can be sent to provide after sales service.

Basically, GN Solids America LLC receives 1 or 2 sets 40Ft containers that filled with shaker screens every month. One 40ft container holds 1000 pcs to 1500 pcs shaker screens. Plus those 5000~6000 pcs screens in Houston warehouse, GN Solids America LLC is able to provide shaker screens to USA customer in a short period. For those large customers need shaker screens, GN Solids America LLC will deliver the container to customer warehouse directly.

- Details

-

Published: 22 February 2018

GN Solids Control manufactures thousands of shaker screens every year. GN shaker screens are delivered to over seventy-two countries and regions until now, almost all the large drilling companies are using GN shaker screens.

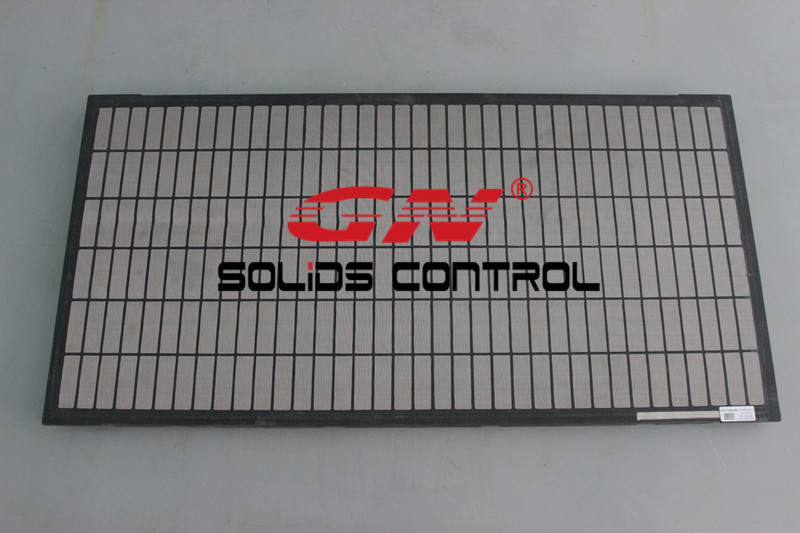

Now there are 2 types of common seen shaker screens in the market: one type if metal frame screens and the other type is composite frame screens. GN Solids Control shaker screen factory were manufacturing metal frame screens, while now GN Solids Control is mainly focused on manufacturing composite frame shaker screens.

GN Solids Control has done hundreds of compare tests: same drilling rig, two parallel shakers fixed with metal frame screens and composite frame shaker screens separately. All the testing reports show GN made composite frame screens are much better than metal frame screens. Actually, GN Solids Control also did some compare tests by using GN made composite screens and OEM metal frame screens, the testing results are still the same. So why GN made composite frame screens are much better than those OEM metal screens?

1. GN composite frame screen has larger effective using area

Due to the structural difference, GN made composite frame screens are using less supporting frame, so the effective using area is larger than metal frame screens. As we all know, a larger treating area also means a larger treating capacity.

2. GN composite frame screen is pre-tensioned

Most shaker screens manufacturers not pretension wire cloth before heat press. On the other side, wire cloth is much easier to glue on the composite frame screen panel if you compared with metal and metal glue.

3. Composite frame has a better cushion character

When the composite frame screens are fixed on the shaker deck, composite frame will eat some crash force due to composite is more flexible.

GN Screens are using the same wire cloth vendor as Mi-Swaco and Derrick. GN Solids Control also hired one USA third party to test GN made screens in order to strictly conform to API RP13 C standard.

- Details

-

Published: 13 February 2018

GN Solids Control is one the largest shaker screens manufacturers. GN Solids Control manufactures various products, such as shale shaker, cuttings dryer, centrifuge, feeding pumps and whole treating unit.

GN Solids Control standard equipment are usually socking either in GN Houston warehouse or GN China 2 manufacturing plants. Now GN Solids America Houston warehouse also has thousands of shaker screens in stock.

GN Shaker screens are the most cost effective products. GN Solids Control provides replacement screens for global famous brands, such as replacement screens for King Cobra or Cobra, replacement screens for Mi-Swaco Mongoose, replacement screens for FSI5000, replacement screens for Derrick (includes Derrick 500 and Derrick 2000) etc. GN Solids Control also provides customized solution for the other types shaker screens, as long as you could tell us the shaker screen size, we can manufacture shaker screens for you.

GN Solids Control is especially good at providing and manufacturing composite frame shaker screens. GN Solids Control has many composite frame moud which can be used to manufacture at least 5000 pcs screens every month.

Every year, GN Solids Control participates in CIPPE and some other oil and gas shows. GN Solids Control has been attending CIPPE for many years, this year GN Solid Control will exhibit composite frame shaker screens in Beijing CIPPE. GN composite frame shaker screens are keeping improving based on the feedbacks we collected from different drilling rig sites.

According to the testing reports from our customers, GN Solids Control shaker screens are even better than the OEM shake screens. If you compare the price, you will be heavily impressed by GN shaker screens price.

Most of GN shaker screen competitors are not testing their screens through a third party, but GN Solids Control actually hired one third party from USA to test our screens in order to conform with API RP 13C.

- Details

-

Published: 01 February 2018

GN Solids Control is looking for screen partners or distributors in Canada and Central America. As one of the largest shaker screens manufacturers, GN Solids Control manufactures over 5000 pieces shaker screens every month which covers most of the shaker screens, such as replacement screens for King Cobra/ Venom, FSI, Mongoose, Derrick, etc. GN Solids Control opened one branch company in Houston, TX in 2013. With the opening of GN Solids America LLC Houston, GN Solids Control also built one large warehouse which can be used to stock more than 6000 pcs shaker screens.

GN Solids America LLC has provided thousands of shaker screens to North America and Central America drilling customers. GN Solids shaker screens have been widely tested that they are last longer than traditional metal frame screens and also have a better separating performance.

GN Solids America would like to invite some partners who are devoted to develop market with the best-selling product. As we know, shaker screens are wearable parts, screen users need to change the them every 5 to 7 days based on the drilling slurry they are treating. Once you have one customer and they are satisfied with GN shaker screen, they will keep purchasing these screens.

GN Solids Control is very confident on the shaker screens quality as GN engineers have spent many years to develop and test the screens. GN Solids Control is especially good at providing composite frame shaker screens. Compare to the traditional metal frame ones, GN composite frame screens have larger effective using room. Most of shaker screen manufacturers are using 3 layers wire cloth for shaker screens above API 120, while GN Solids uses 3 layers for screens API nos above 50. This increase the material cost and manufacturing period, but it’s totally worth judging from the separating performance.

- Details

-

Published: 26 January 2018

GN Solids Control is one of the top leading solids control and waste management equipment manufacturers. GN Solids Control has built one USA branch company in Houston, TX and one office in Moscow, Russia. With GN fast development, more and more global customers are loving to use GN Solids Control and Drilling Cuttings Treating Equipment.

GN Solids America LLC is focused on to providing the best service for North America and South America customers. GN Solids America LLC now is stocking over 10 sets of shale shakers, 4 sets mud cleaners, 4 sets decanter centrifuges and 1 cuttings dryer in Houston. Roughly GN Solids Control has over 5000 pcs shaker screens in Houston, which can basically meet all the needs of shakers screens usage. And GN Solids America LLC also receives at least 1 or 2 40Ft containers every month which filled with thousands shaker screens.

GN Solids America LLC has received thousands of inquiries on solids control and waste treating systems, today we would like to share one project we received before:

Our Company an Engineering Procurement, Construction and Logistics Servicing Company with it operational head office in USA. We have just received an Invitation for Technical Tender (ITT)

Having gone through your website, it will please you to know that we which to partner with your company as our Technical Partners for this project.

We will also appreciate you give us the Profoma invoices for the Total cost of a complete Solid Control Equipments unit, but not limited to the Three (3) types of Solid Control Equipment you showcased/advertised in your website.

Kindly advise your wiliness to our proposal, with your terms and conditions and I will forward to you the ITT documents, giving us in detail your contact person to liaise with for this project. Please do accept the assurance of our highest regards, as we look forward to you quick response.

- Details

-

Published: 17 January 2018