8.4# Centrifuge &Disc-centrifuge

Slurry in #1 centrifuge tank is pumped by #2 screw pump into #2 centrifuge: solids fall into cuttings box, liquid falls into #2 centrifuge tank and then feed into #1 disc-centrifuge by an inline pump to finish 3 phase separating: oil , water and solids. Dis-centrifuge needs water to discharge when working, a water tank is fixed one one side of #2 centrifuge tank. Meanwhile, on the other side of the centrifuge tank, an inline pump is used to feed slurry.

9.5# Disc-centrifuge & Surge Tank

1# disc-centrifuge treated oil goes into #5 unit’s #1 oil surge tank, water goes into #1 water surge tank. Slurry in #2 oil surge tank of #5 unit is pumped into #2 disc-centrifuge by inline pump: oil goes into #1 oil surge tank, water goes into #1 water tank and solids discharged to the outside. When the oil in #1 oil surge tank reaches to a certain level, liquid level alarm monitors the level and gives signal so the inline pump can transfer slurry into appointed position. At the same time, #1 water surge tank slurry is transferred to #6 gravity oil/water separator by an inline pump.

10.6#Gravity Oil/Water Separator, Water tank

Inline pump transfers slurry into #6 Gravity Oil/Water Separator: oil goes to #6 unit’s #3 oil surge tank and water goes to #6 unit’s #2 water surge tank. Slurry in #2 water tank is transferred by an inline pump to micro bubble treating unit for further treatment. Inline pump and pipes are fixed near #2 water surge tank, in case water is not clean enough, it can be pumped into #5 unit’s #2 oil surge tank and to be further treated by #2 disc-centrifuge.

11. Oil tank

Inline pump transfers the slurry into #7’s micro bubble treating unit, after treated: clean water is send into #7’s water tank and provide recycled water; oil goes to #6 unit’s #3 oil surge tank which is monitored by liquid level alarm. Inline pump is used to transfer the slurry into appointed area. With the whole system runs, waste sludge can be recycled and also solve the environment pollution issue.

12.Chemical Dosing unit

All outside pipes; all inlets are controlled by valves on and off; can add chemicals/water in different position.

- Details

-

Published: 22 February 2019

GN Oil Sludge System Working Process

Oil sludge in the V-Tank is separated by gravity into different layers after mixed by the bottom screw conveyor, the top floating oil (large portion) is transferred by a diaphragm pump into #2 oil surge tank, and the left small portion oil is feed into afterwards shaker shaker by centrifugal pump to finish the first phase separating.

GN Shale shaker can separate out most of those large solids, liquid is feed into #1 GN Decanter Centrifuge by screw pump where the second phase separating is achieved.

Solids treated by GN Centrifuge fall into the bottom tank of #1 centrifuge and diluted a second time. And liquid goes to #4 Centrifuge and Disc-Centrifuge Treating Unit’s Tank. Slurry in #1 centrifuge tank is transferred by #2 screw pump and feed into #2 Centrifuge to further separate: solids are collected by a GN cuttings box; liquid is fall into #2 Centrifuge tank, a inline pump is used to feed it into #1 Disc-Centrifuge where solids, oil and water is treated at the first time: oil goes to #5 unit’s #1 oil surge tank; water goes to #5 unit’s #1 water surge tank; solids discharge to the outside.

Slurry in #2 oil surge tank of #5 unit is feed into #2 Disc-Centrifuge by inline pump: oil goes to 1#oil surge tank; water goes to 1#water surge tank; solids discharge to the outside.

Slurry in 1#water surge tank of #2 unit is feed into #6 GN gravity oil/water separator by inline pump: oil goes to #6 unit’s #3 oil surge tank, water goes to 6# unit’s #2 water surge tank and then feed by another inline pump to #7 micro bubble treating unit: clean water goes to #7 unit’s water tank, provide recycled clean water for this whole system; oil goes to 3#oil surge tank of #6 unit. A oil pump is fixed on #3 oil surge tank, in case the oil is not clean enough, oil pump can transfer back to #2 oil surge tank, and then treated in 2#GN disc-centrifuge again until reach the final treating demands.

- Details

-

Published: 23 January 2019

GN Solids Control manufactures different sizes of decanter centrifuges. GN 9inch bowl centrifuges are largely used in small volume slurry treating, such as the chemical slurry, pharmacy slurry, diamond drilling slurry etc.

There are hundreds sets of GN 9 inch centrifuges working in USA and Canada. Several weeks ago, GN Solids Control provide 6 sets to a USA customer. This customer will use GN centrifuge to treat Aluminum Oxide Slurry.

The Aluminum Oxide slurry solids content is around 8% to 10%, customer would like to thickening the slurry into 60% to 80%. By using a chemical mixing tank with a GN mud agitator, the solids Aluminum Oxide Slurry is mixed with water first. Then it is feed into GN 9 inch bowl centrifuge by using GN screw pump.

In order to eliminate those finer solids, GN chemical dosing unit is also used. Sometime, customers might not want to use chemical dosing unit due to environment protection rules, because using chemicals might cause pollution. One GN Slant Plate Clarifier might be used after the slurry treated by GN decanter centrifuge.

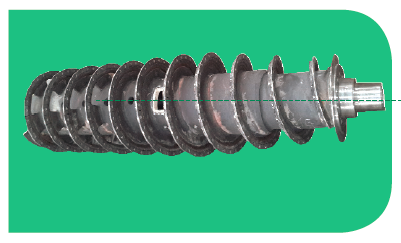

GN 9 inch centrifuge has 2 models: variable speed and fix speed. GN 9 inch centrifuge is mainly including the following components: rotating bowl, screw conveyor, centrifuge frame and driven motors. Some customer also purchase GN centrifuge rotating assembly (rotating bowl and screw propeller) to modify by themselves. GN 9inch centrifuge now has 2 version, the D version is fixed by only one driven motor while the E version is fixed with 2 driven motors.

GN Solids America LLC is located in Houston, TX. GN has several 9 inch centrifuges in stock as well the other models such as 14inch centrifuge. GN Solids Control centrifuge has a wide usage for different slurry separation. Please feel free to connect with GN sales for your decanter centrifuge usage.

- Details

-

Published: 19 January 2019

GN Solids Control manufactures different models transfer pumps or conveying equipment. As long as the materials can be moved, they can be transferred by GN pumps.

There are many pumps distributors are selling pumps that made by GN Solids Control. Today we would like to share several pumps we provided to our customers.

1.GN Centrifugal Pump

GN made centrifugal pumps are replaceable with NOV Mission Magnum pumps. GN centrifugal pumps are widely used in move different slurry. In the solids control and waste management treating area, GN centrifugal pumps are largely used to feed drilling mud into GN desanders and GN desiltes as well as GN Mud Cleaners.

Centrifugal pumps are wearable pumps, they wear fast when the slurry has too much solids inside. Pump shell and impeller must take extra protection process in order to run for a long time.

2.GN Screw Pump

GN Screw pump is also called GN positive displacement pump. This pump has a very large push force for high density drilling mud. It’s mainly used as a feeding pump of the decanter centrifuge.

Screw pump can not be used when there are too much solids (over 30%), it will get blocked easily. So a GN shale shaker must be used if there are too much solids.

3.GN Submersible Pump

GN Submersible pump is mainly used to transfer slurry with high content solids and larger particles. It can be also used as a feeding pump for GN decanter centrifuge.

4.GN Vacuum Pump

GN Vacuum Pump is a newly developed equipment to transfer all materials to a long distance (max. 1000m). Different with the above mentioned pumps, GN vacuum pump is driven by air force. If those above pumps need to consider the explosion-proof standards, then you don’t need to worry about GN vacuum pump. But you will need to use an air compressor to provide enough air to driven the vacuum pump for sure.

- Details

-

Published: 11 January 2019

GN Solids Control has provided thousands of solids control and waste management equipment to global customers this year. Last month, GN Solids Control shipped a large quantity of solids control equipment to one Russia customer.

Here are the main solids control equipment we provided:

1. 8 Sets Shale Shakers

GN Shale Shaker is the first treating unit when drilling mud comes from the drilling rig. By using different API nos. shaker screens, GN shale shaker help to remove most of the solids larger than 100 microns.

2. 6 sets Mud Cleaners

GN mud cleaner is GN shale shaker fixed with 4inch cyclones and 10 inch cyclones. Usually 10inch cyclones remove solids larger than 55microns while the 4 inch cyclones help to eliminate solids larger than 25 microns.

3. 3 sets Centrifugal Degassers

GN centrifugal degassers are especially designed to use in narrow working room if the mud tank is too small. It plays the same function as the vacuum degasser.

4. 4 sets Decanter Centrifuges

GN decanter centrifuges are the most cost effective treating equipment which are largely used in solids and liquid separation, not only in the oil and gas solids control and waste management treating area, but also widely used in the other slurry treating, like hydrovac slurry treating, mining slurry treating etc.

GN decanter centrifuges are using tungsten carbide tiles to protect the screw propeller for long time usage. GN centrifuge rotating bowl is made by centrifugal casting. Now GN has 9inch, 14inch, 18inch, 22inch and 30 inch bowl centrifuge for choose.

5. 10 sets Centrifugal Pumps

Centrifugal pumps are largely used to transfer solids. GN made centrifugal pump is interchangeable with NOV Mission Mangum pumps.

6. 2000 pcs Shaker screens

Beside those above treating equipment, customer also purchased 2000 pcs shaker screens from GN. All screens are composite frame ones, which are much better than traditional metal frames ones. GN Houston warehouse also has thousands screens in stock.

- Details

-

Published: 05 January 2019