CIPPE is coming right the next week! We, GN Solids Control would like to give our sincere invitations to global customers.

As we all know, CIPPE is one of the world largest oil and gas shows in the world. Every year, CIPPE will have one show in Beijing and one show in Shanghai. GN Solids Control has been participating in these shows for many years.

This year GN Solids Control will exhibit the following equipment, welcome to visit our booth in Beijing New Exhibition Center.

1.GN Oil Sludge Treating Unit

GN oil sludge treating unit is a turnkey solution for oil sludge treatment, it includes: premixing-heating tank, shale shaker, decanter centrifuge, 3 phase disc-centrifuge, chemical dosing unit and some other auxiliary part.

2.GN Shale Shaker

GN shale shaker is one of the most popular treating equipment in the world. Shaker is largely used to treating solids and liquid mixed slurry.

3.GN Decanter Centrifuge

Another pop star equipment of GN, GN decanter centrifuge are largely used by global customers. Now GN Solids Control provides different centrifuges that can be used in oil and gas area and some other solids and liquid separation area. GN decanter centrifuges are also used in hydro vac slurry treating, mining slurry treating, HDD mud treating etc.

4.GN Centrifugal Pump

GN made centrifugal pumps are totally replaceable with NOV mission magnum pumps. Centrifugal pump is one effective transfer pump. GN Solids Control use a lot of centrifugal pumps to feed mud cleaners.

5.GN Shaker Screens

GN Solids Control manufactures thousands of shaker screens every year, which can be used to replace world famous brand shaker screens such as Mongoose shaker screens, Derrick shaker screens, FSI shaker screens, NOV Venom or King Cobra Shaker screens.

BTW, OTC show will be exhibited in May. Welcome to visit us in Houston. Both GN Solid Control and GN Solids America LLC has one booth.

- Details

-

Published: 23 March 2019

GN Solids Control manufactures different types of feeding pumps, such as centrifugal pump, submersible pump, screw pump, vacuum pump etc. All GN made pumps can be used to transfer solids and liquid.

GN Solids Control made centrifugal pumps are largely used to transfer solids and liquid, every year GN manufactures over 1000 centrifugal pumps that are using in more than 70 countries and regions. GN made centrifugal pumps are totally interchangeable with Mission Magnum pumps, many USA pump manufacturers are using GN pump parts to repair the OEM magnum pumps.

GN centrifugal pumps can be used as feeding pumps for desander or desilter. Drilling mud can be also used to transfer by centrifugal pumps between different mud tanks. As GN centrifugal pump is a wearable parts, GN Solids Control engineers use mechanical seal made with tungsten carbide. Besides, a packing seal is also used. GN centrifugal pump’s impeller is designed to use pretty low axial trust loads, this particular design is convenient for installation, maintenance and repair.

Besides the above mentioned advantages, here are more factors when you choose a good centrifugal pump:

1.GN centrifugal pump is using concentric design to minimize abrasive wear and lower the turbulence. In order to have longer using life, GN centrifugal pumps are using strong concentric and thick casing.

2.GN centrifugal pump casing is made from hard ductil iron alloy. This material can upgrade the abrasion-proof capability.

3.GN centrifugal pump is designed to have a wide open-vane impeller which helps to low the axial thrust, so bearing life can be extended.

4.In case of the improper motor hook-up, GN used anti-loosening impeller lock bolt.

5.Mechanical seal is high quality brand no-adjustment type, it provides long using life and zero leakage. Shaft sleeve is replaceable.

6.GN Solids only used op brands bearings.

7.By using casting method to manufacture the centrifugal pump skid, GN Soilds Control makes sure te centrifugal pump has less vibration and reliable operation.

- Details

-

Published: 17 March 2019

GN Solids Control shipped multiple sets shakers and decanter centrifuges to a Indian customer last month. As a global solids control and waste management system provider, GN Solids Control has provided millions of treating equipment and turnkey solutions to thousands of customers.

GN Solids America LLC is a branch company of GN Solids Control, it was established in 2013 in Houston, TX, USA. With the opening of GN Solids America, GN Solids Control is able to stock thousands of shaker screens, tens of shakers and centrifuges in Houston. All the shale shakers, decanter centrifuges, centrifugal pumps and shake screens can be delivered to customer in a short time. For this Indian customer, GN Solids Control provided 6 sets shale shakers and 2 decanter centrifuges.

1.GN Shale Shaker

6 sets GN shale shakers are using GN 4 panel screens shaker, use same size of Mi-Swaco Mongoose screens. GN shakers are designed under fully stress analysis. GN shakers are using USA Martin vibrators or Italy OLI vibrators. Usually 2 sets shale shakers are distributed by a box feeding box or pipe feeding box.

GN Solids Control also manufactures shaker screens, mainly composite frame screens. GN shaker screens cover most of the popular size shaker screens, they can be used to replace Derrick shaker screen, Venom screen, king cobra screen, FSI screen and Mongoose screen etc.

2.GN Centrifuge

2 sets GN decanter centrifuge systems are provided together with those shale shakers. Each decanter centrifuge is fixed on the top of the centrifuge skid with a screw pump and VFD control box on the skid.

GN decanter centrifuge is the most cost-effective treating centrifuge in the world. Bearing temperature and vibration switch are optional. GN centrifuge rotating bowl is made by centrifugal casting. GN screw propeller also protected with tiles made of tungsten carbide.

Welcome to visit GN Houston office to check GN shale shakers and centrifuges.

- Details

-

Published: 08 March 2019

GN Solids Control is a leading decanter centrifuge manufacturer in China. Now GN Solids Control centrifuge covers 9 inch bowl centrifuge, 14inch bowl centrifuge, 18inch bowl centrifuge, 22inch bowl centrifuge and 30inch bowl centrifuge. GN decanter centrifuges are widely using in various solids and liquid separation area, such as drilling mud separation, dredging water treating, chemical separation, oil sludge separation and industrial water treating etc.

GN Solids Control centrifuge had variable speed and fix speed control model, based on the working environment, GN Solids Control centrifuges have Zone I or Zone II explosion-proof centrifuge.

As we all know, GN Solids America LLC is the brand company of GN Solids Control. Now GN Solids America has some decanter centrifuges stocking in Houston warehouse. Customer can pick up centrifuge from GN Houston warehouse directly without waiting for the long time shipping.

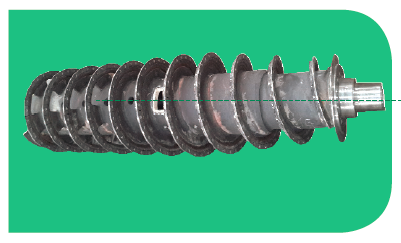

Today we would like to give everyone a short introduction of GN 9 inch bowl centrifuge. GN Centrifuge is mainly including the following components: rotating bowl, screw propeller, supporting frame and 2 driven motors.

GN centrifuge rotating bowl is made by stainless steel, as whole piece is made by centrifugal casting without welding. Inside the rotating bowl, screw propeller is protected by tungsten carbide tiles based on the using conditions.

Due to the portable character of GN 9 inch bowl centrifuge, it’s largely used in remote area for diamond drilling or core drilling mud control so helicopter can move it can move it conveniently.

9 inch centrifuge is also called GN baby centrifuge, the treating flow rate is around 50GPM which is pretty popular in many labs for test scale usage. Last year, GN solids worked together with some USA laboratories and research centers, many scientists are using GN 9 inch bowl centrifuge to treat slurry and eliminate finer particles larger than 2 to 5 microns.

- Details

-

Published: 02 March 2019

8.4# Centrifuge &Disc-centrifuge

Slurry in #1 centrifuge tank is pumped by #2 screw pump into #2 centrifuge: solids fall into cuttings box, liquid falls into #2 centrifuge tank and then feed into #1 disc-centrifuge by an inline pump to finish 3 phase separating: oil , water and solids. Dis-centrifuge needs water to discharge when working, a water tank is fixed one one side of #2 centrifuge tank. Meanwhile, on the other side of the centrifuge tank, an inline pump is used to feed slurry.

9.5# Disc-centrifuge & Surge Tank

1# disc-centrifuge treated oil goes into #5 unit’s #1 oil surge tank, water goes into #1 water surge tank. Slurry in #2 oil surge tank of #5 unit is pumped into #2 disc-centrifuge by inline pump: oil goes into #1 oil surge tank, water goes into #1 water tank and solids discharged to the outside. When the oil in #1 oil surge tank reaches to a certain level, liquid level alarm monitors the level and gives signal so the inline pump can transfer slurry into appointed position. At the same time, #1 water surge tank slurry is transferred to #6 gravity oil/water separator by an inline pump.

10.6#Gravity Oil/Water Separator, Water tank

Inline pump transfers slurry into #6 Gravity Oil/Water Separator: oil goes to #6 unit’s #3 oil surge tank and water goes to #6 unit’s #2 water surge tank. Slurry in #2 water tank is transferred by an inline pump to micro bubble treating unit for further treatment. Inline pump and pipes are fixed near #2 water surge tank, in case water is not clean enough, it can be pumped into #5 unit’s #2 oil surge tank and to be further treated by #2 disc-centrifuge.

11. Oil tank

Inline pump transfers the slurry into #7’s micro bubble treating unit, after treated: clean water is send into #7’s water tank and provide recycled water; oil goes to #6 unit’s #3 oil surge tank which is monitored by liquid level alarm. Inline pump is used to transfer the slurry into appointed area. With the whole system runs, waste sludge can be recycled and also solve the environment pollution issue.

12.Chemical Dosing unit

All outside pipes; all inlets are controlled by valves on and off; can add chemicals/water in different position.

- Details

-

Published: 22 February 2019