-

GN

-

GNLW454GT

-

Mud Dewatering Centrifuge

-

Decanter Centrifuge

-

Hydrovac Excavation

-

GNLW454GT for Hydrovac Mud Treatment

-

High G-Force Mud Centrifuge for Mining

-

GN Solids Control Hydrovac Dewatering Equipment

-

18-inch Decanter Centrifuge for Wastewater

-

Efficient Mud Separation Centrifuge

- Details

-

Published: 21 November 2025

GN Solids Control has completed a full Dewatering Unit package—featuring the GNLW224 horizontal decanter centrifuge, polymer dosing unit, and sludge dewatering centrifuge—now ready for Factory Acceptance Test (FAT) for an overseas client.

Traditional solids-control equipment removes particles above 5 microns, while ultra-fine solids continue accumulating in the drilling mud. To stabilize fluid properties, operators often dilute mud with large volumes of water, increasing both cost and waste.

To solve this, GN provides a chemically enhanced Dewatering Unit that uses polymer flocculation and high-speed separation to remove solids below 5 microns. This produces cleaner water suitable for reuse or controlled discharge—reducing water consumption and waste generation.

How the dewatering process works:

-

The automatic dosing system prepares polymer solution.

-

A slurry pump transfers mud into the decanter centrifuge.

-

Polymer is injected into the feed line via the dosing pump.

-

Chemical and mud are fully mixed in the feed tube.

-

The high-speed centrifuge separates ultra-fine solids and improves fluid quality.

GN also offers 20-ft and 40-ft containerized Dewatering Unit packages for drilling mud treatment, municipal sludge, tunneling, and environmental applications.

The upcoming FAT will verify mechanical performance, dosing accuracy, automation logic, and full system integration before shipment. As a global supplier, GN continues to deliver efficient and reliable separation solutions for drilling and industrial projects worldwide.

Keywords

-

GN GNLW224 dewatering centrifuge

-

Polymer dosing system for drilling mud

-

Containerized drilling mud dewatering unit

-

Chemically enhanced fine solids removal

-

Dewatering centrifuge for ultra-fine solids

-

Dewatering Unit

-

dosing system

-

GN Solids Control

-

decanter centrifuge

-

drilling mud treatment

- Details

-

Published: 14 November 2025

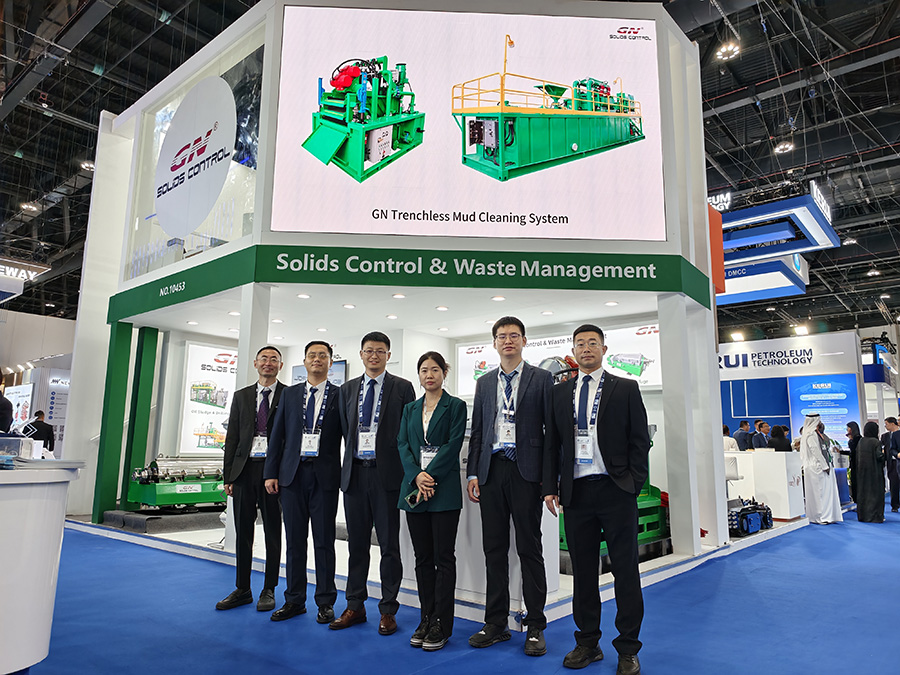

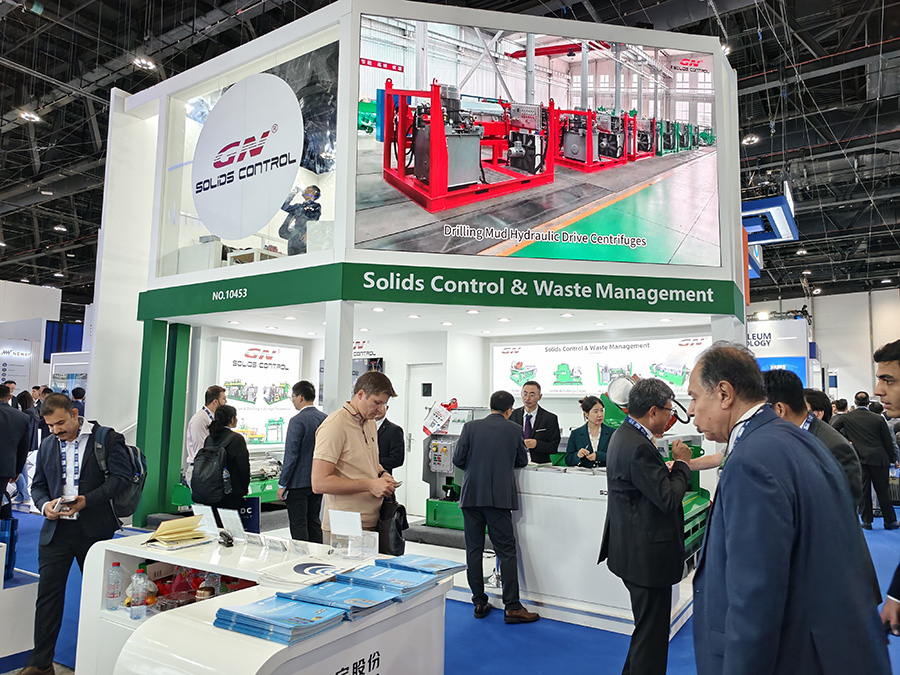

From November 3rd to 6th, 2025, GN Solids Control successfully showcased its advanced separation technology at ADIPEC 2025, one of the world’s largest and most influential oil and gas exhibitions. Located at Booth No. 10453, Hall 10, GN’s booth attracted both long-term partners and new visitors from across the global energy industry.

This year, GN highlighted two of its core products — the Decanter Centrifuge and the Shale Shaker. These equipment samples demonstrated GN’s commitment to efficient, reliable, and environmentally responsible solids-liquid separation solutions. Visitors were particularly impressed by the high-quality build and innovative design that enhance oilfield performance while minimizing environmental impact.

As oil and gas operations continue to focus on sustainability, GN Solids Control remains at the forefront of providing technologies that reduce waste, recover valuable resources, and protect the environment. Through continuous innovation and global cooperation, GN aims to make oil development cleaner, smarter, and more efficient.

The success at ADIPEC 2025 further strengthened GN’s position as a trusted global partner in solids control and waste management systems. GN sincerely thanks all visitors for their support and looks forward to deepening cooperation in future projects.

Keywords:

-

GN Solids Control

-

ADIPEC 2025

-

Decanter centrifuge

-

Shale shaker

-

Separation technology

6. solids control equipment for oilfield

7. environmental-friendly drilling waste management

8. high-performance decanter centrifuge for oil and gas

9. shale shaker for drilling mud recycling

10. sustainable solids control solutions for energy industry

- Details

-

Published: 07 November 2025

Recently, multiple sets of GN K Series Linear Motion Shale Shakers have been successfully delivered to a valued client in the Middle East for use in their drilling fluids solids control system.

As the first-stage solids control equipment, the Shale Shaker plays a crucial role in the overall performance of the drilling mud system. The GN K Series shale shaker is designed and manufactured by GN Solids Control, integrating advanced technology from both domestic and international sources, as well as GN’s own engineering innovations.

The GN K Series shale shaker offers several key advantages:

-

High G-force and wide screen area ensure efficient solids separation.

-

The entire shaker deck is heat-treated to relieve welding stress, providing strong vibration endurance.

-

Equipped with Italian OLI brand vibration motors for reliable performance.

-

Quick screen tightening system allows fast installation and replacement.

-

Nylon wedge blocks and polyurethane sealing components enhance wear and corrosion resistance, ideal for high-temperature drilling environments in the Middle East.

-

The adjustable deck angle design provides flexibility to handle different mud conditions and flow rates.

GN provides several models within the K Series, including GNZS594K, GNZS595K, and GNZS596K, covering a wide range of drilling applications from oil & gas to trenchless HDD. Proven in numerous international drilling projects, GN shale shakers are recognized for their durability, reliability, and cost efficiency.

For more details, visit: https://www.gnsolidscontrol.com/shale-shaker

Keywords:

GN Solids Control, Shale Shaker, Drilling Mud System, Solids Control Equipment, Linear Motion Shaker,

GN K Series Shale Shaker for Middle East Market, High G Force Linear Motion Shale Shaker,

Oilfield Drilling Fluids Solids Control System, GNZS594K GNZS595K GNZS596K Shale Shakers,

Reliable Shale Shaker for Harsh Drilling Environments

- Details

-

Published: 24 October 2025

8 Sets of GN Jet Mud Mixing Hopper Units Delivered to European Drilling Client

GN Solids Control is proud to announce the successful delivery of 8 sets of Jet Mud Mixing Hopper Systems to a valued European drilling service company. Each system includes a 90KW GNSB8×6 centrifugal pump, a drilling mud mixing hopper, and a heavy-duty steel base, forming a complete and reliable mud mixing package for field operations.

The GN Jet Mud Mixing Hopper is designed for accurate and efficient preparation of drilling fluids. Using a Venturi jet design, it creates strong suction to mix bentonite, barite, and polymers evenly into the drilling mud system. GN offers two standard models — GNSLDSC (500–1500 GPM) and GNSLDMC (200–500 GPM) — both available in stainless steel or carbon steel construction. The modular layout allows easy installation on mud tanks or independent skids, offering flexibility for different drilling site configurations.

To ensure powerful circulation and stable pressure, each system is equipped with a GNSB Series centrifugal pump. These pumps are widely recognized for high efficiency, robust design, and spare parts interchangeability with NOV Mission Pumps. The GNSB8×6C-13J model delivers up to 320 m³/h flow rate and 35 m head, perfectly matching the jet hopper’s demand for high-performance mixing.

Key features of GN centrifugal pumps include tungsten carbide mechanical seals, ductile iron impellers, open-vane design for reduced axial thrust, and top-brand bearings for reliable, low-maintenance operation. The cast skid base provides excellent alignment and minimizes vibration, extending both pump and motor lifespan.

GN Jet Mud Mixing Hopper Systems have been successfully applied in oil & gas drilling, HDD, and geothermal projects across the world — including the Middle East, Russia, and South America. This new delivery to Europe once again showcases GN Solids Control's strength in providing API and ISO 9001 certified mud mixing and solids control equipment that meet international quality standards.

As a trusted global manufacturer, GN Solids Control remains committed to delivering innovative, efficient, and reliable drilling fluid systems — helping operators achieve better mud quality, improved drilling efficiency, and reduced operational costs.

Tags: #JetMudMixingHopper #CentrifugalPump #SolidsControl #DrillingFluids #GNsolidscontrol #MudMixingSystem #OilfieldEquipment

- Details

-

Published: 17 October 2025