GN Solids Control is a leading manufacturer on solids control equipment and drilling waste management equipment. Ever year, GN Solids Control manufactures 300 sets to 500 sets shale shakers for global customers, over 70% are using outside of China.

GN Solids Control now has 3 different manufacturing plants close to Beijing International Airport, with a Houston Branch Company: GN Solids America LLC and a Russian Branch Company: GN Solids Russia.

GN Solids America LLC has been providing hundreds of solids control equipment in North America and South America. GN Solids Control made decanter centrifuges and shale shakers are widely accepted by drilling rig contractors to treat drilling mud/waste.

Weeks ago GN Solids Control finished manufacturing a large order for a Indonesia customer. In this order, it has almost 20 sets shale shakers and 6 sets mud cleaners.

GN Solids Control shale shakers have 2 panels shaker, 3 panels shaker and 4 panels shaker. GN Solids Control has been working closely with top research and universities when develop new equipment. Before when we designed the shale shaker, we have done theory testing by using Ansys and a long time on site testing to make sure everything is going well.

GN Solid Control only uses 2 famous brands on the vibration motors include USA Martin and Italy OLI. GN shaker deck is using stainless steel to protect the shaker from rusty. A 2.6mm sealing C type groove is also fixed on the shaker deck so the sealing rubber is easy to fix, which is one of GN patent for better protection shale shaker and extend the shaker screens using life.

Besides the shaker, GN Solids Control also manufactures shaker screens. Every month, GN Solids Control manufactures more than 6000 pieces of shaker screens, which cover most of those famous shakers. GN made screens are also largely used to replace OEM screens.

- Details

-

Published: 01 September 2019

GN Solids Control is a leading manufacturer on solids control equipment and drilling waste management equipment. Ever year, GN Solids Control manufactures 300 sets to 500 sets shale shakers for global customers, over 70% are using outside of China.

GN Solids Control now has 3 different manufacturing plants close to Beijing International Airport, with a Houston Branch Company: GN Solids America LLC and a Russian Branch Company: GN Solids Russia.

GN Solids America LLC has been providing hundreds of solids control equipment in North America and South America. GN Solids Control made decanter centrifuges and shale shakers are widely accepted by drilling rig contractors to treat drilling mud/waste.

Weeks ago GN Solids Control finished manufacturing a large order for a Indonesia customer. In this order, it has almost 20 sets shale shakers and 6 sets mud cleaners.

GN Solids Control shale shakers have 2 panels shaker, 3 panels shaker and 4 panels shaker. GN Solids Control has been working closely with top research and universities when develop new equipment. Before when we designed the shale shaker, we have done theory testing by using Ansys and a long time on site testing to make sure everything is going well.

GN Solid Control only uses 2 famous brands on the vibration motors include USA Martin and Italy OLI. GN shaker deck is using stainless steel to protect the shaker from rusty. A 2.6mm sealing C type groove is also fixed on the shaker deck so the sealing rubber is easy to fix, which is one of GN patent for better protection shale shaker and extend the shaker screens using life.

Besides the shaker, GN Solids Control also manufactures shaker screens. Every month, GN Solids Control manufactures more than 6000 pieces of shaker screens, which cover most of those famous shakers. GN made screens are also largely used to replace OEM screens.

- Details

-

Published: 01 September 2019

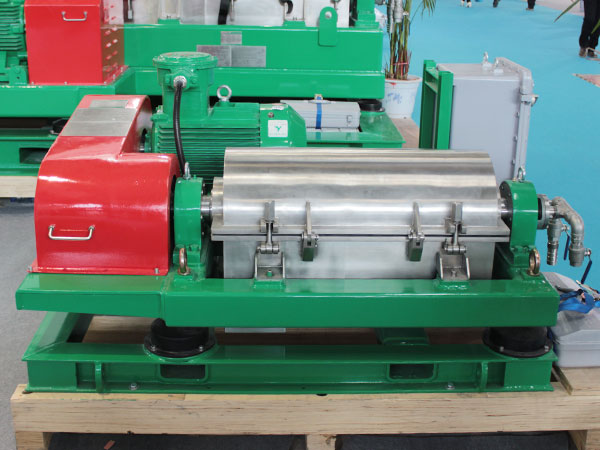

GN Solids Control manufactures different rotating bowl sizes of centrifuge, which cover the 9 inch bowl, 14inch bowl, 18 inch bowl, 22 inch bowl and 30 inch bowl. Different centrifuges are using in different area. Today we would like to give a detail introduction about GN 9 inch bowl centrifuge which we also called baby centrifuge or mini centrifuge.

GN 9 inch centrifuges are largely using in diamond drilling, core drilling, label scale slurry treating as the flow rate is around 30 gpm. Every other years, GN Solids Control upgrade its equipment in order to have a much better working performance. Now the 9 inch centrifuge GN Solids Control manufacture is the D version which comes from the original A version gradually.

GN 9 inch centrifuge bowl is also made of duplex stainless steel by centrifugal casting like the other GN bigger bowl centrifuges. There are mainly 2 models: one is fixed with single driven motor and the other model is driven by 2 separated motors.

GN 9 inch centrifuge also provides fix speed control and variable speed control to choose. Usually, if you only treat one slurry, use the fix speed is more cost effective, anyway it can also change speed by using different pulleys and belts. While the VFD is more convenient to adjust the rotating speed on the control box.

GN Solids Control is also open to provide only the centrifuge rotating assembly without motor and centrifuge foundation. Customer can choose to make it their own brand by assembling motors and paint in different colour with their own logo.

Every year, GN Solids Control manufactures and sells about 300 sets decanter centrifuges, among them 50 sets are GN 9 inch bowl centrifuges.

GN 9 inch bowl centrifuges are very popular in North America and South America, many local diamond drilling companies or mining slurry treating companies are using GN made centrifuge.

Sometimes, if there are too many large particles in the slurry, a shale shaker will be highly recommended to add in front of the centrifuge.

- Details

-

Published: 25 August 2019

GN Solids Control manufactures different kinds of pumps including vacuum pump, submersible pump, screw pump and centrifugal pump. As one of the newest transfer pumps, GN Solids Control vacuum pump can transfer a large variety of sludge, especially sludge with high content solids and large particles.

By using GN vacuum pump, solids less than 75 microns can be transferred, and max. Solids content is 80%. GN Solids Control manufactures 3 models: GNSP-10, GNSP-20 and GNSP-40, flow rate is 10 m3/h, 20 m3/h and 40 m3/h separately..

GN vacuum pump is a air driven pump, need to have air flow when working, so an air compressor is mandatory. Due to GN vacuum pump is composed of mechanical parts and pneumatic parts without any electrical components, it can be used in any explosion-proof environment includes IEC, ATEX Zone 1 or 2.

GN Solids Control shipped 4 sets vacuum pumps to Africa weeks ago. This customer ordered 2 sets vacuum pumps with wheels which is GNSP-10 and GNSP-20, also 2 sets skid mounted larger pump GNSP-40. Customer will use these 4 pumps to transfer drill cuttings that discharged from shaker, desilter and desander. Also the smallest pump GNSP-10 is used to collect and clean drill cuttings fall to the ground during moving.

GN vacuum pump inlet need to within 8 m in order to have a better separating performance when moving slurry/sludge. Two timers are fixed on the control box which can be rotated easily to adjust the working time. Suck and discharge time is set at a certain no. Before leave factory.

GN vacuum pump actually is a off and on transfer pump, it sucks the slurry first and then switch to discharge, suck and discharge takes turns to work. In order to meet customers demands, GN Solids Control provided several different types of inlet ports and outlet ports for customer to choose, such as when transfer the drilling cuttings discharged from cuttings dryer, cuttings can fall into GN vacuum pump directly, while the discharge outlet is connected with a rotating port for cushion.

- Details

-

Published: 15 August 2019

GN Solids Control just shipped some solids control equipment includes shakers, mud cleaners and decanter centrifuges to a Russian customer. GN Solids Control manufactures more than 500 sets shale shakers, 200 sets mud cleaners and 300 sets decanter centrifuges every year.

As one of the very important markets of GN Solids Control, Russian has hundreds of oil and gas drilling rigs, every year GN Solids Control provides some solids control equipment to Russia.

Here are those solids control equipment GN Solids Control just shipped to customer:

1.GN Shale Shaker

GN Solids Control provides 2 sets shale shakers GNZS594, both of them are 4 panels shakers. GN shaker is using only 2 brands vibrators: one is USA Martin and the other is Italy OLI, especially for those shakers delivered from USA, GN Solids America buys from USA directly.

2.GN Mud Cleaner

As treated by GN shale shaker, large solids (usually large than 100 microns) can be separated out, then GN mud cleaner is used to eliminate finer solids.

GN mud cleaner is composed of 10 inch cyclones and 4 inch cyclones that can separate solids in 2 different size ranges.

All those shaker screens used on GN shale shaker and GN mud cleaner is made by GN. Every month, GN Solids Control sells more than 6000~8000 pieces shaker screens to worldwide customers. GN Solids Control is especially good at manufacturing composite frame shaker screens. GN shale screens are tested by a USA third party, so all screens that are strictly comply with API RP 13C standard.

GN shaker screens have many different types, except those screens can be used on GN shale shaker, GN composite frame screens can be also used to replace the other popular screens such as replacement screens for Derrick, Mongoose, Fluid System, Brand/ Venom etc.

3.GN Decanter Centrifuge

GN decanter centrifuge is the star separating equipment when use in solids control and drilling waste management. Different sizes can be provide to satisfy your needs.

- Details

-

Published: 09 August 2019