GN Solids Control equipment has provided thousands of solids control systems that used for onshore and offshore drilling rigs. As we all know, GN Solids Control has manufactured and provided solids control equipment to more than seventy countries and regions.

It’s relative easier to provide solids control systems for onshore drilling rigs, while it’s a little more complicated when using for offshore drilling rigs. Today we would like to share one solids control system that we provided to a COSL offshore rig.

It mainly includes these treating equipment: shale shaker, mud cleaner, decanter centrifuge, mud tank, centrifugal pump and screw conveyor.

1.Shale Shaker

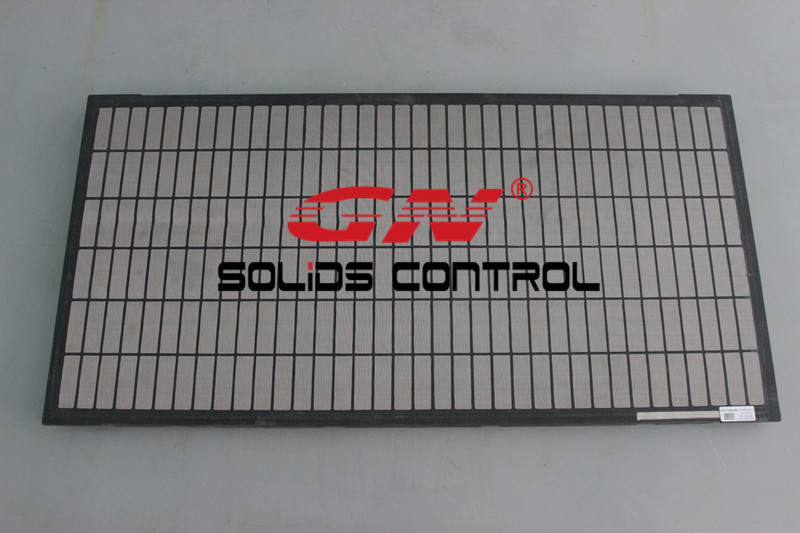

GN shale shaker is one of the most cost-effective shakers in the world. GN shaker deck is all stainless steel. GN patented C-type groove is using 2.8 mm thickness SS, which is inserted with rubber to have a long time protection of shake screens. Also GN Solids Control made varieties of shaker screens includes GN own screens and the other popular sizes.

2.Mud Cleaner

GN mud cleaner is a 3-in-1 treating unit: GN shaker, GN desander and GN desilter. It is a 2 phase treating unit as desander separate solids larger than 55 microns and desilter eliminate solids larger than 25 microns.

3.Decanter Centrifuge

GN decanter centrifuge plays a very important role in drilling mud separating. GN Solids Control provides different sizes bowl centrifuges which are widely using in barite recovery, solids control , thickening and dewatering. GN Solids Control provides VFD control box that suits for IEC Ex, ATEX explosion-proof environment. DNV lifting certificate is also provided for the offshore usage.

4.Mud Tank

GN mud tank is the storage tank to keep the drilling mud and also the foundation of all the above treating equipment as they will all fixed on the top of the tank. Centrifugal Pumps and Screw Conveyors are also provided in this system as auxiliary treating equipment.

- Details

-

Published: 04 August 2019

GN Solids America LLC is a branch company of GN Solids Control. Every year, GN Solids Control provides many solids control equipment to USA and Canada customers, most of the equipment are shipped from GN Houston warehouse.

GN Solids Control products now cover all the solids control equipment and drilling waste management equipment, solids control equipment such as shale shaker, desitler, desander, mud cleaner and decanter centrifuge; while drilling waste equipment mainly includes decanter centrifuge and cuttings dryer.

GN Solids America LLC opened in 2013, we are still a baby company compared to our USA friendly competitors, but with the great support from GN Solids Control, GN Solids America has been growing really fast these years.

Last month, GN Solids Control shipped another batch of solids control equipment to GN Houston warehouse. Usually, GN Houston warehouse keeps some shale shakers, decanter centrifuges, centrifugal pumps and shake screens stocking in Houston, many spare parts are also stocking in Houston in case customers need it urgently.

Although now all the solids control equipment shipped to USA are charged 25% tariff due to the USA government last year’s tariff policy, GN Solids Control actually enjoyed a large solids control business growth since last July.

In those containers shipped to GN Houston warehouse, there are 6 sets shale shakers and 2 sets decanter centrifuges.

GN Solids Control received many shale shakers and decanter centrifuges orders from North America and South America. BTW, GN Solids Control also provided some sets of hydraulic driven decanter centrifuges to Middle East.

Shale shake and decanter centrifuge are two of the most popular used treating equipment. GN Shale shakers are largely used to eliminate solids larger than 100 microns, and GN decanter centrifuges are mainly used to separate solids larger than 2~5 microns. Welcome to visit our Houston warehouse if you need any solids control equipment.

- Details

-

Published: 20 July 2019

GN Solids Control has designed hundreds of solids control and waste management treating systems for Global customers for many years. Among those systems, GN Oil Sludge Treating Systems is one of the most popular one.

GN Oil Sludge Treating System is mainly designed to treat high density and large viscosity sludge/slurry, such as the oil sludge from refiner plant, oil tank bottom sludge and drill cuttings.

Several weeks ago GN Solids Control provided another 2 sets oil cuttings treating systems to a Russian customer. Both of these 2 systems are put in a separate standard container.

Here are the main GN standard equipment in this system:

1.GN Cuttings Dryer

GN Cuttings Dryer is mainly designed to treat oil base cuttings and synthesized base cuttings. GN cuttings dryer can eliminate solids larger than 250 microns, and oil in the final cuttings can be controlled less than 5%.

GN cuttings dryer has 3 different sizes screen baskets when treating different solids.

2.GN Decanter Centrifuge

GN decanter centrifuge is one of the most popular solids control and drilling waste treating equipment. GN decanter centrifuge if classified by rotating bowl sizes there are 9 inch bowl centrifuge, 14 inch bowl centrifuge, 18 inch bowl centrifuge, 22inch bowl centrifuge and 30 inch bowl centrifuge.

GN 14 inch centrifuge and GN 22 inch centrifuge are two of the most popular sizes in drilling mud solids control and drill cuttings waste management area.

3.GN Chemical Dosing Unit

In order to eliminate finer particles, GN decanter centrifuges are equipped with one set of GN Chemical Dosing Unit. Flocculent is added when feed the slurry into Decanter Centrifuge at the same time.

4.GN Container

GN cuttings dryer and GN decanter centrifuge is fixed inside of the container. Customer is able to move these 2 containers conveniently among different sites, also in Russian cold winter it is more comfortable to work inside the container compared to work outside.

- Details

-

Published: 14 July 2019

All GN Solids Control equipment are made in China. Here in USA we do some assembly and repair work, some spare parts and wearable parts are also available in GN Houston, USA.

It’s not doubt that customers can always find a cheaper price in China, but you do get what you paid for. GN Solids Control is devoted to provide the most cost-effective solids control equipment and waste management equipment, our equipment quality can even beat USA made brand. We will never ever try to cut our cost by using poor quality materials, all of our components are top brand, such as the centrifuge 2 main bearings we use genuine SKF bearing, the main electrical components we use ABB or Siemens.

'Seeing is Believing', the most direct way is visit GN China manufacturing plant and also visit the other vendors. To be honest, many China solids control manufacturers were the former employee of GN, they left GN with the former version drawings and started a new company. We actually didn't pay much attention to them, our largest advantage is we keep upgrading our equipment year by year based on thousands of sites feedback, such as the shaker we upgraded to F version (the previous version is A, B, C...).

Every year hundreds of customers visit GN manufacturing plant, after they visited the other vendors' factories all of them will come back to us. Quality control is vital important for us and also for our customers, this is also the main reason why Baker Hughes, Bariod, Shell, OXY etc keep using our equipment. And you will never need to worry about the after sales service, either our engineers in USA or in China can be send to your work site in 48 hours.

Suggest you check with the other Vendor and see whether they can provide a convincing project reference as we provided, also checked on the after sales service.

- Details

-

Published: 08 June 2019

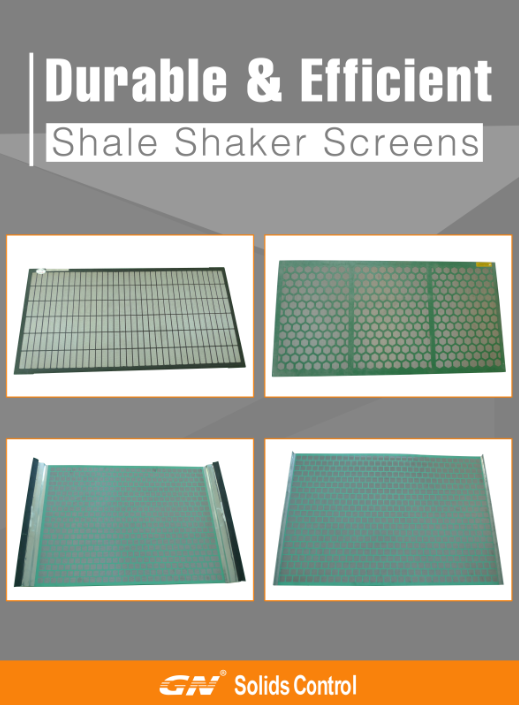

GN Solids Control has been manufacturing shaker screens for many years. Now GN Houston branch company which is GN Solids America LLC has thousands of shake screens in stock.

GN Shaker screens are widely used in hundreds of drilling rig sites. As we all know, shaker screens are wearable parts, they all need to be changed after used for some days in order to have a clear drilling mud. GN made shaker screens can be used on most those largely used shakers, such as NOV shaker, Mi-Swaco shaker and Derrick Shaker etc. Before GN Solids Control manufactured hundreds of metal frame shaker screens, but with the new technology usage, more and more customers prefer to use composite frame shaker screens. GN made composite frame shaker screens are tested to last longer than traditional metal frames, which are also provided during parallel testing.

GN Solids Control is always devoted to provide the most cost-effective shaker screens to global customers. Even in US, many customers keep using GN shaker screens.

So why GN made composite frame shaker screens are better than those metal frame ones?

1.GN composite frames screens are using new technology. Inside they are still metal frames which are welded by automatic robot welding, and the screen frame are sent to Inject Moulding machine to cover a layer of high quality plastic.

2.By using the same screen cloth manufacturer with Derrick and Mi-Swaco, GN Solids Control keeps the screen quality at high standard.

3.Most shaker screens manufacturers are using 3 layers screen cloth when API no. Larger than API 120, while GN Solids Control use 3 layers start from API 60. From this point, GN shaker screens can also long longer.

4.GN Solids Control is the first the only one that can pass the third party test report.

Call our Houston office 713-878-0880 for your screen needs.

- Details

-

Published: 25 May 2019