Screw conveyors are an essential part of drilling operations in the oil and gas industry. They play a crucial role in efficiently transporting drilling cuttings and other materials from the drilling site to designated locations. When it comes to safety, GN SOLIDS CONTROL, a leading manufacturer of drilling equipment, understands the importance of adhering to Kuwait's safety standards. Here are some key features of GN SOLIDS CONTROL's screw conveyors that meet the safety requirements: Steel Grating Cover Plates: GN SOLIDS CONTROL's screw conveyors are equipped with steel grating cover plates to prevent accidental contact with the moving parts of the conveyor, ensuring the safety of operators and other personnel around the equipment. These cover plates provide a protective barrier while allowing for smooth material flow. HSE Safety Signs: GN SOLIDS CONTROL's screw conveyors are clearly marked with HSE (Health, Safety, and Environment) safety signs, indicating potential hazards and providing important safety information to operators and workers. This helps in promoting a safe working environment and reducing the risk of accidents.

Emergency Stop Pull Cord Switch: GN SOLIDS CONTROL's screw conveyors are fitted with emergency stop pull cord switches, strategically located along the conveyor, which can be easily accessed by operators in case of an emergency. This allows for quick and efficient shutdown of the conveyor in hazardous situations, ensuring the safety of personnel and preventing potential accidents. Spray System: GN SOLIDS CONTROL's screw conveyors are equipped with a spray system that prevents the conveyor from getting clogged. The spray system sprays water or other appropriate liquids on the conveyor, preventing the material from sticking and blocking the conveyor, which could lead to operational disruptions and safety hazards. Collapse-Proof Steel Grating Design: GN SOLIDS CONTROL's screw conveyors feature a collapse-proof steel grating design. This design ensures that the steel grating cover plates remain intact even under heavy loads, preventing collapse and ensuring the safety of personnel who may be working on or around the conveyor.

In conclusion, GN SOLIDS CONTROL's screw conveyors for drilling companies in Kuwait are designed and manufactured in accordance with safety standards. With features such as steel grating cover plates, HSE safety signs, emergency stop pull cord switches, spray systems, and collapse-proof steel grating design, GN SOLIDS CONTROL's screw conveyors prioritize safety, providing a reliable and safe solution for drilling operations.

- Details

-

Published: 06 April 2023

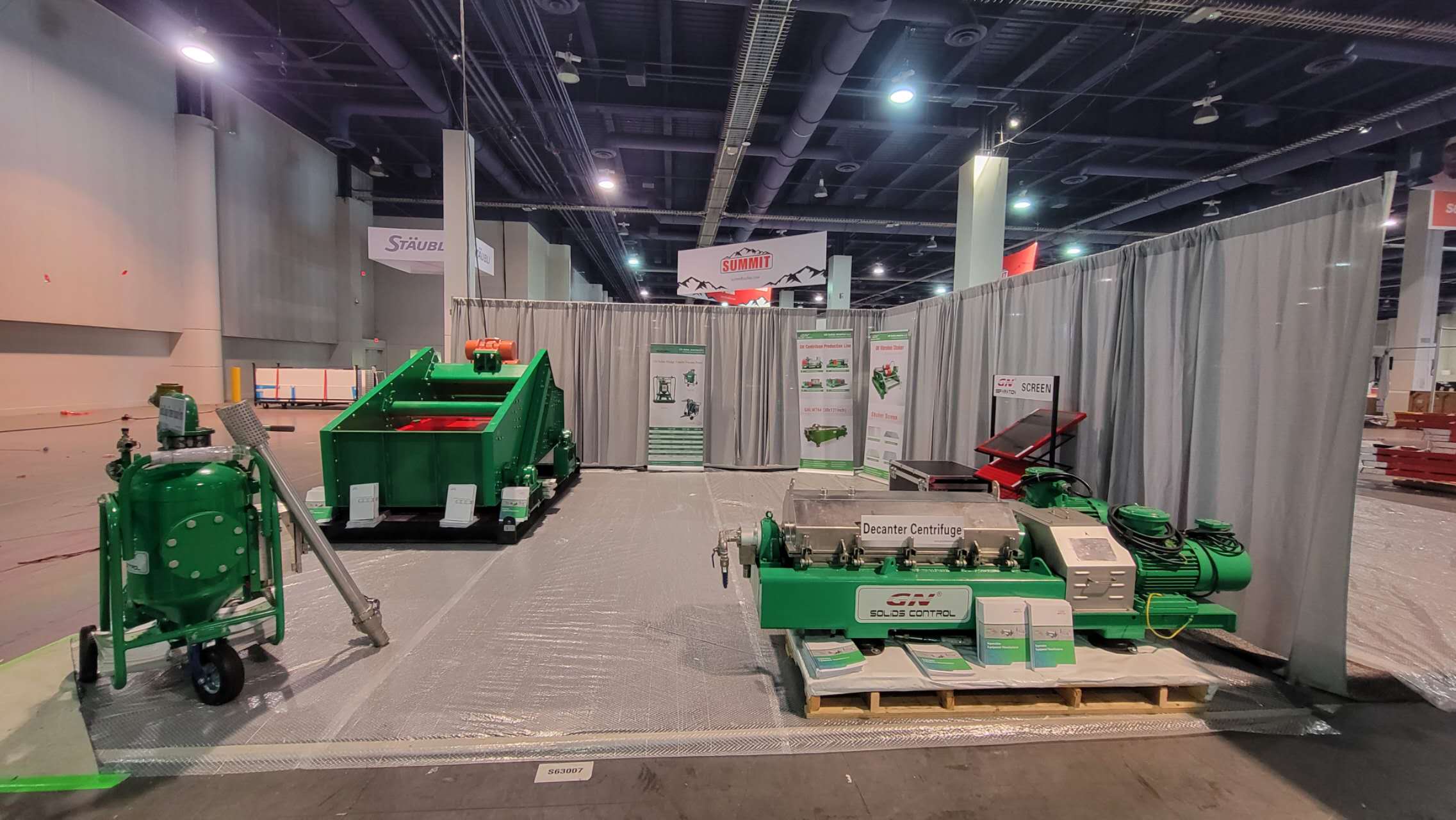

Conexpo 2023, which has a history of nearly a hundred years, was held at the Las Vegas Convention and Exhibition Center in the United States from March 14th to March 18th, local time. The exhibition was organized by the American Manufacturers' Equipment Association, Jointly hosted by the National Asphalt Pavement Association and the American Sand and Gravel Association, it is an important platform for the industry to showcase the latest technologies, equipment and exhibits. GN solids America bring the decanter centrifuge, solids vacuum pump and mining vibrating screen for this exhibition.

In the past 3 days show, lots old client visited GN booth, share the experience of past three years on the solids liquid separation project. meanwhile ,client directly purchased Decanter centrifuge and vacuum on this exhibition.Especially the solids vacuum pump, which attracted lots people. We introduced vacuum pump for lots time, It is different with normal pump, it drive by high pressure air. Which is used to transfer the high solids content material, sometimes it even can transfer some the dry solids. It is good option to help people transfer some material that the traditional pump is not workable.

The second equipment is Decanter centrifuge ,this equipment is widely used for solids liquid separation.GN decanter centrifuge has a series model with different treating capacity and different separation purpose. GN 14 inch Decanter are famous to use on the drilling mud treatment on oil gas industry. The big length diameter ratio centrifuge are good performance on the waste water treatment. Our biggest model GNLW 764, which can treat 120 cuber meter per hour. It is high efficiency for mining industry. Such as the coal dewatering, diamond slurry separation.

In this show, we only display 3 equipment, actually, we have many solids liquid separation equipment. welcome to contact us to know more. we will be pleased to recommend the suitable equipment for your project.

- Details

-

Published: 17 March 2023

Vertical cutting dryer is one kind equipment of waste management in oil gas industry. It main used on the drill cutting treatment especially the oil base drill cutting. Last week we delivered one vertical cutting dryer and one Decanter centrifuge to mud company. According to client requirement, all equipment was installed in container for insulation and easily transport in different job site.

As we all know, drill cutting is high pollution since include lots chemical, meanwhile the contented liquid is expensive. Separate the liquid out and recycle it, and dryer the solids. These measure are very important to protect environment and reduce the cost of drilling mud.

In this system there are vertical cutting dryer and Decanter centrifuge. Both devices are utilize same principle. When the machine are in high rotational motion, the inside material will bear separation force. Along with the speed faster, separation G force will be higher. Due to the solids and liquid are different density. They will bear vary separation force. High density bear bigger force, and it will settle down onto the bottom of centrifuge bowl, and liquid will be on higher layer. This program will achieve the solids and liquid separation. After that, the solids and liquid will be discharge from different outlet port.

Decanter centrifuge was designed with higher separation G force, normal can over 3000G. Vertical cutting dryer only about 900 RPG . This different designing lead to the cutting dryer can process the material with high solids content such as drill cutting, but the discharge liquid is not clear . On the contrary, material for Decanter centrifuge normally less than 10% for solids content. But the discharged liquid is much clear. This is why we use Decanter centrifuge for further treating to the liquid discharged from vertical cutting dryer.

Sometimes we use high G shaker to treat water base drill cutting and then use Decanter centrifuge. If you have these kind requirement ,welcome to contact us.

- Details

-

Published: 10 March 2023

Solids vacuum pump is one of the most featured equipment of GN solids control. It was developed and started to sell in 2017. A brand new equipment for high solids content material transfer. As we all know GN is focused on solids control equipment to serve oil gas industry for petroleum drilling project. His equipment main used to treat the drilling mud ,to recycle it and clean it for reuse. And help customer to reduce the using of drilling mud, and save more.

Actually GN solids control has the centrifuge pump, submersible pump for drilling slurry transfer. But in some other project, client need to transfer the high solids content such as drill cutting that is very viscosity, and sometime with big size particle. The normal pump is no way to this kind material. So we built this solids vacuum pump. Which is driven by high speed pressure air, need air compressor to provide air source to run it. This pump is simple structure with high work performance. Last week we delivered one unit GNSP-40B pump to China customer for the tunnel boring slurry transfer. This project is located in downtown of city. So user need the pump be quiet, we design special device to reduce noise.

This 40B pump can transfer 40 cube meter clean water per hour. The capacity will reduce along with the solids content be higher and higher. This pump has long distance transfer ability, which can reach 1000 meters when transfer clean water, and the most suck distance is about 500 meters. It can be used in most project. However, this pump is poor to suck material for low place. It utilize vertue to generate vacuum to suck the material. So it is poor to suck material from low place. Sometimes ,it also be affected by the location altitude. Please double check with GN before using this pump for your project.

- Details

-

Published: 03 February 2023

This week we completed 2 sets solids control equipment ,and ready to delivery to Bolivia customer. Last year, we already shipped 2 units Decanter centrifuge to same customer. We are so glad that client give good feedback to our equipment, and also honored that cooperate with this so kind customer who is so professional in solids control area and understand well to GN equipment.

These solids control equipment running well under the operation of our client , and bring profit to them. In this order, there are total 4 units decanter centrifuge, and 8 units centrifuge and 2 units screw pump. Each screw pump is used to feeding slurry to Decanter centrifuge. all equipment were 100% designed and manufactured by GN. The core equipment of this solids control equipment is Decanter centrifuge. GNLW363-VFD is the most featured products for solids control using in oil gas industry. Whatever the water base drilling mud or oil base mud, GNLW363-VFD can treat them with good effect. This is profit from our team keep upgrading the design and strictly quality control during manufacturing. GN has strict and high requirement to supplier, we care money, but more concern quality. Almost all the supplier is from the famous brand of global or China. Such as the bearing, paint, electrical component etc. The centrifuge was design according to the most harsh situation. We are always happy and open to hear advice from customer, actually we keep collecting the quality feedback from customer, and adjust design to make it more popular by customer. Decanter centrifuge is just one of products. We can provide the whole series solids control system, built customized mud system specially for client project. The good quality and quick service helped us to get lots long term partner in the global. If your project have demanded on these equipment, welcome to contact us.

- Details

-

Published: 08 January 2023