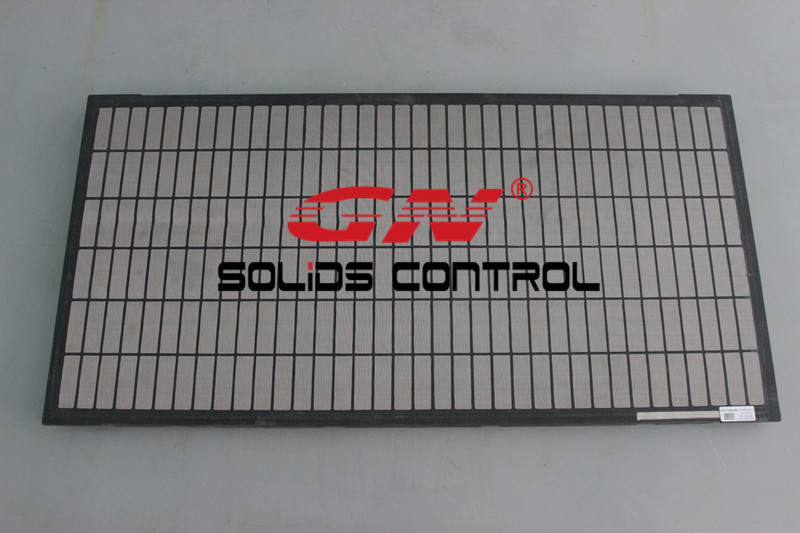

GN Solids Control has been manufacturing shaker screens for many years. GN Solids Control shaker screens can be widely used to replace world famous shaker screens, such as shaker screens for Mongoose, Derrick, Brant (King Cobra or Venom), FSI and Elgin shaker screens. GN shaker screens are widely known due to the most effective feature.

GN Solids Control now manufactures over 5000 pieces shaker screens monthly. Most of the shaker screens are composite shaker screens. Before GN Solids Control were mainly provide metal frame shaker screens. GN Solids Control engineers have been upgraded the shaker screens manufacture process, so most of the shaker screens are composite material shaker screens.

If you compare the Composite Shaker Screens with GN Metal Frame Shaker Screens, you will find that GN composite shaker screens are very cost effective although the price is a little bit higher. The frame of GN composite shaker screens is welded by automatic robot, so the inside metal frame has a very good welding seam. And the outside frame is using high quality plastic. The composite shaker screens are made by using mould, so the shaker screens’ frame can be kept in a very good consistency even we manufacture over 5000 pieces every month.

Due to the special pretension technology, GN composite material shaker screens can be used for a longer time than the metal frame shaker screens. As most of competitors are using 2 layer cloth to manufacture the shaker screens for API no. below API 140. While GN Solids Control uses 3 layer wire mesh to manufacture shaker screens when the API no. is larger than API 60.

It’s obviously to know that GN metal frame shaker screens are a little bit heavier than the metal frame shaker screens. So when changing the screens after used for a while on the shaker, GN composite shaker screens are more convenient to change and clean.

The most important thing is GN composite shaker screens can be used 20~30% time longer than the metal frame shaker screens before broken in the same working condition.

- Details

-

Published: 02 December 2016