Most People is just engaged in drilling work tend to reduce every expenditure without knowing about drilling engineering, and believing this will reduce drilling costs. If each work is not interdependent, reducing the cost of each work will minimize the total drilling cost. For example, it is cheaper to weight drilling fluid with drilling cuttings than barite. But the next unpredictable question is how much it will cost to deal with it. This situation is caused by the inherent nature of drilling cuttings

A common mistake is usually caused by misunderstanding about reducing drilling costs, such as allowing drilling fluid to initially use cuttings to increase its density. Obviously, if no other weighting components are added to the drilling fluid, the cost of drilling fluid will be very low, and its theoretical basis is easy to find. However, there are too many cuttings in the drilling fluid and little removal, which will increase the additional cost. Another common mistake often occurs when using weighted drilling fluid. It is mistakenly believed that the weighted material will be removed when removing drilling cuttings. The increased cost of removing weighting materials (barite or iron ore powder) is far less than the cost of dealing with complex or accidents caused by drilling cuttings. In the high cost offshore drilling environment, this view is correct and has its particularity. Even in low-cost onshore drilling, most views tend to prefer to remove some weighting components rather than excessive cuttings in the drilling fluid. Proper selection and use of drilling fluid solid-phase control equipment, combined with correct selection of drilling fluid system, usually results in low drilling cost. The drilling rig will drill many different types of wells every year. It is wise to equip the equipment on the drilling fluid tank, and it can also save investment. On the contrary, another common mistake is to think that the removal of solid phase requires different drilling fluid tank arrangements for different drilling fluid systems. A cuttings removal system suitable for water-based, oil-based and synthetic based drilling fluid systems is established. Solid phase control can be carried out for polymer, high-density or low-density water-based drilling fluid.

GN Solids Control is manufacture with more than 15 years experience for solids control equipment manufacture. If you have demand, we will be pleased provide technical support and equipment.

- Details

-

Published: 08 January 2022

As we all know there will be large drill cutting when drill well, especially in the petroleum drilling ,as long as the more drilling depth, the drilling mud is the most important thing decide if we can finish the drilling work, bad drilling mud will directly destroy the well and eve rig machine. How to remove out drill cutting is main job for solids control and guarantee the fluid property.

However, some remarks that drilling cuttings are beneficial to drilling fluid are wrong. He did not realize that cobalt cuttings have existing and potential harm to drilling fluid. Generally speaking, the phenomenon that drilling cuttings increase the solid content of drilling fluid will not appear soon. The harm has a certain process, and the economic impact can not be shown to us soon. Therefore, these people do not believe that the harm of drilling cuttings to cobalt well fluid can reach the extent of their actual damage. Drilling cuttings will increase the drilling cost, damage the reservoir and increase the cost of drilling fluid treatment. Therefore, drilling cuttings are related to the following special problems: (1) filtrate damages the reservoir; 2) Limited cobalt velocity (3) complex downhole; (4) Stuck drill; (5) Lost circulation (6) direct cost of drilling fluid; (7) Increased processing costs.

In the actual drilling work ,the drilling cutting may have more damage. Therefor use the good quality solids control equipment to remove out drilling cutting and make the good property drilling fluids is very important. GN Solids Control has manufacture solids control equipment for more than 15 years. We can provide the whole set mud system from mud mixer to the management of drilling cutting. Shale shaker ,mud cleaner, decanter centrifuge, mud agitator, mud jet mixer, and shear pump. We exported these equipment to more than 76 countries and served 2000 customers. If you have requirement to drilling fluid treatment, we will be pleased to share our experience.

- Details

-

Published: 31 December 2021

GN solids vacuum pump is different with the normal market pump. Solids vacuum pump was specially developed to transfer the high solids content material or high viscosity material and also some dry solids, such as oil sludge ,sand, cement ,metal power. It has widely application, and it was known by more and more people. This pump is a new product and most people is not familiar with it ,and have no idea how to trouble shot.

This pump is driven by air, as usually we connect to air pressure. Currently GN has 10B,20B,40B these 3 models. every of them required air supplying are 4 m3 /min, 8m3/min and 17m3/min. And the air pressure should between 0.8Mpa. If the suction power and discharge power is not enough, you may check the air supplying. The suitable Air supply is necessary to support the pump work.

Sometimes, the pump suction air down lowed, we suggest you to check if there is any where have the air leakage, especially in the part of limit Switch. The hose connection may loosen after using for several month. The air leakage will cause the suction and discharge power low. you just need to tighten these air hose and to make sure there is no air leakage.

Solids pump is different with electrical pump, select the suitable length of suction hose and discharged hose. If the suction hose is too long, which may lead the suction power too low. The pump can suck 50 meters when the material is water. However, if the material is more viscosity and higher density, reduce the suction hose length. 6 meters is good choice. The suction height is no more than 8 meters, cause it utilize vacuum power, and suction power was dependent on the atmosphericpressure.

Note to clean the pump after using to transfer material and make sure there is no stuck in valve .If you have any other issue when using it, feel free to contact us .

- Details

-

Published: 25 December 2021

In the last month of 2021,GN just shipped out 3 waste management system to Middle East for the petroleum well drilling project. Actually, this order is from our old client. They had purchased solids control equipment from GN for many times since 2015. As the leader of solids control industry. GN has passed 15 years. At beginning of GN history, we only can manufacture less solids control equipment ,such shale shaker and shaker screens. Currently shale shaker and shaker screen are still our most featured products since we have so many years manufacture experience. GN has the strictly control to the equipment quality even the most simple products, this is also the reason why some many customer cooperate with us for many years. As long as the development of GN, we have great technical department and also most advanced production line. We developed our own full series solids control equipment. GN not only manufacture equipment ,but we are good at provide the customized system for client project according to their special requirement.

This vertical cutting dryer and Decanter centrifuge are used for the oil base drill cutting. As we all know , the drilling mud always content high pollution material, which is hard to be solved by nature even for hundred years. and also drilling is very expensive. It will save money and reduce the pollution to the environment if we can recovery the mud from drill cutting. Vertical cutting dryer is specially used for oil base drill cutting. The oil base waste can directly feed into vertical cutting dryer, which can separate out he mud under the 900 RPM speed. However this speed is adjustable , motor quick more dryer for discharged solids. vertical cutting dryer can recovery more than 95 mud from waste.

After the above step, discharged liquid will be feed into Decanter centrifuge for further separation . Decanter centrifuge can clean the mud ,and reduce the solids content below 5%. The slurry after treatment by decanter centrifuge, which will be clean enough for reuse. And it will return back to solids control system for drilling again. If you need these equipment ,welcome to contact us.

- Details

-

Published: 17 December 2021

Hydro vac is very popular method to drilling in advanced company, especially in north America, such as USA and Canada. It utilize the high pressure water to flushing the ground and dig. This method will not damage the pipeline under ground, and also do not pollute environment. It is a environment friendly and high efficiency digging way. However, hydrovac also will consume lots water. After flushing ground by water, there will be generate large sludge. hydrovac truck will suck these sludge into the tank, and transfer it into somewhere to dump. The sludge dumpling is always trouble for hydrovac company. GN solids control developed the dewatering system for these kind sludge treatment.

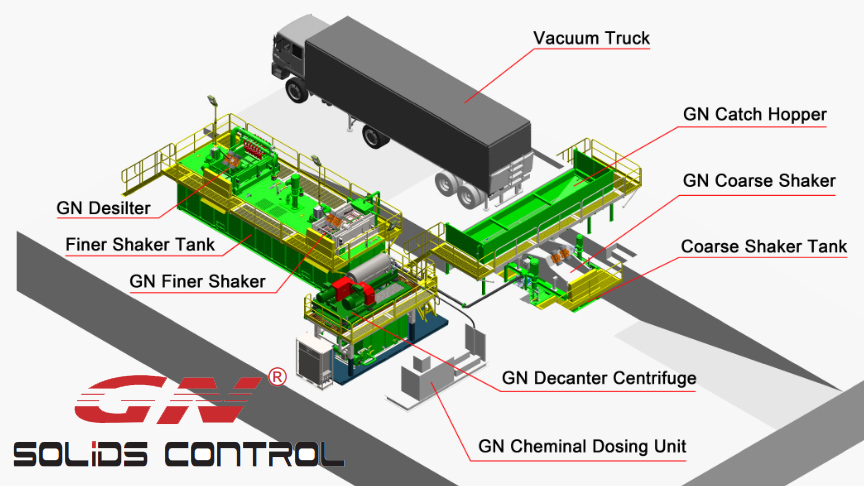

When we design this system, engineer considered the sludge dumpling , solids sort out, solids dewatering and also water clarifying. Firstly, there is a big catch hopper, truck can directly dump sludge into the hopper, this hopper can receive 2-4 truck load sludge in same time, it will save much time for sludge dumpling. Secondly, there is a coarse shaker under Cathy hopper, sludge can drop onto this coarse shaker. It is a big shaker that can separate big size particle , this shaker also has big treating capacity. In this step, shaker can sort out the little stone and big particle sand , which can be used for building material. Slurry after shaker will feed into fine shaker and hydrocyclone ,in this step ,90% solids will be remove out. The discharged solids after sun cure, it will dry enough to transporation and for building material using. The last step is feeding liquid into Decanter centrifuge , some times we also will mix flocculant with liquid to combine tiny solids into bigger to help centrifuge to remove out them better.

The entire system was designed by GN and also manufactured by our own. Customized design it allowable. Till now, we had provide more than 15 sets system to north America, and the sales is keeping raising. If you have demanded on this system, welcome to contact us.

- Details

-

Published: 07 December 2021