As we all know America mining industry is very strong, especially in Canada and some countries of Latin America, such as Peru, Columbia, Chile etc. There are some many mining in these countries. In the mining process, it will consume large water to flush the mineral, and generate lots of water. That is always big issue for mining industry , especially in coal mining. Actually these slurry include lots mining can be recycled.

This week, we delivered 1 coal slurry treatment system to our Columbia client. It is GNLW554-ET Decanter centrifuge, and several screw conveyor ,and screw pump. In this coal mining, client use water to flush mineral ,and large cola slurry accumulate in the pit. Which is one kind pollution and also waste to source. Client need to handle these slurry as soon as possible. We recommend our GNLW554 Decanter centrifuge. This centrifuge diameter is 22 inch , and almost 88 inch length. It’s capacity can reach 60 cubic meter per hour. Which is specially designed for mining industry. The longer centrifuge make sure the material stay longer time inside centrifuge bowl, that means the solids liquid can be separated more complete. and we can get more dryer coal and more clean water.

In this system, we also provide screw conveyor. It will catch the discharged coal from Decanter, and transfer it to pointed place. Both the Decanter and screw conveyor are automatic, continuous working for 7x24 design. In this coal slurry, most solids are tiny size coal power. But in some other mining such as iron, copper, there always some big particle bigger than 2mm. When separate these slurry, pre-treatment is very necessary to remove out these big size particle. So we will add one shale shaker in the system for pre-treatment before feeding into Decanter centrifuge.

Decanter centrifuge is widely used in the mining industry. We are getting more and more orders from America market. Our Houston branch always response quickly to client inquiry and after sale service. If you have demand on our equipment, welcome to contact us.

- Details

-

Published: 06 August 2021

With 13 years development, GN solids control served more than 80 countries customer from different industry. At beginning ,most our client from oil gas industry, and our equipment was used for the drilling mud treat. As long as our development and the experience accumulation, GN separation equipment was applied in mining industry, especially our Decanter centrifuge was very popular in the market. We also built our own sales channel all over the global. GN Solids American as our US branch for the America market, and also Russia office. Except these, there are also many our exclusive agency in different countries. MP as our Canada partner main in charge with the 223 decanter centrifuge selling for mining industry.

MP is also a manufacture , and they are very familiar with mining industry. Based on Canada local situation, we only provide the centrifuge rotating assembly, and they will assembly the control panel, motor ,equipment base by themselves. This mini Decanter centrifuge get the good reaction from customer. It is very convenient for diamond core drilling and minging explore. This centrifuge is almost the smallest Decanter centrifuge in the world. The treating capacity is between 100-120L per minute. low electrical consume, and convenient to transportation in wild. The centrifuge bowl used ss2005 steel which has very goods strength and also anti-wear.

Only in Canada market, our partner sell out more than 50 sets, as long as the economic turn well after corona virus , we believe they will get better sales target. GN always give the full support to their partner ,not only in technical ,payment terms, re-stocking , but also we will help our agency develop the market , recommend the potential client to them.

We have series separation and conveyor equipment, Decanter centrifuge, shale shaker, mud cleaner, screw press, centrifuge pump ,vacuum pump etc. All these equipment has widely application in different industry. if you have demand or you want to be our agent , welcome to contact us.

- Details

-

Published: 31 July 2021

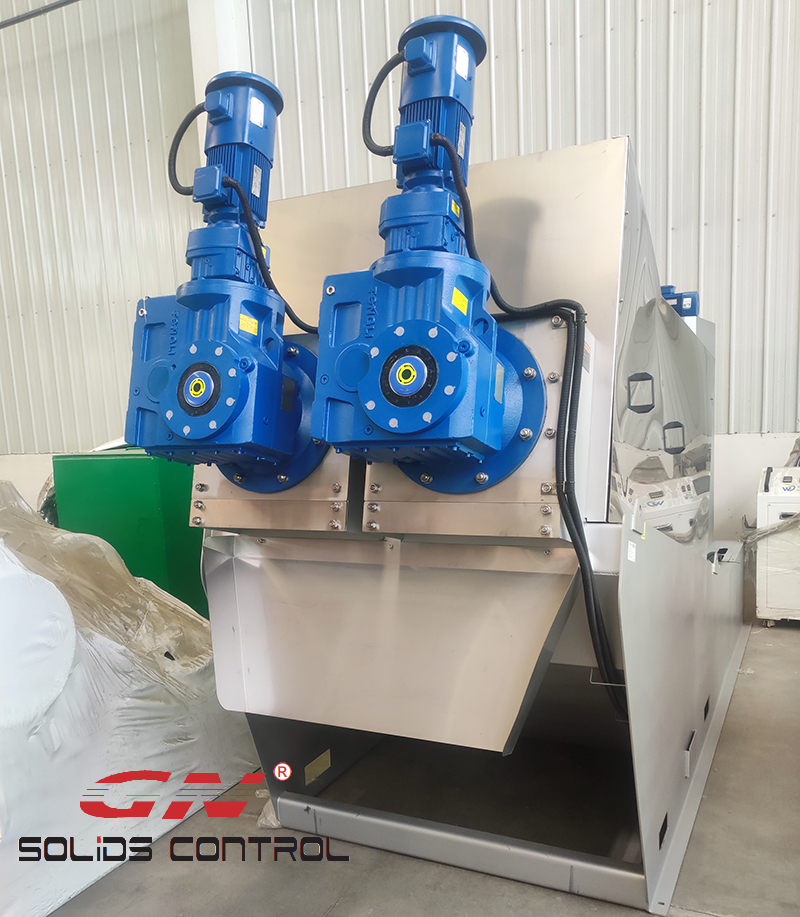

Screw press dewatering machine is one new product for GN. Which is developed as our old client requirement. It is also one kind solids-liquid separation equipment, but difference with decanter centrifuge, screw press is through press the material to dewater. Decanter centrifuge utilize the separation force that generate under the high rotated speed. The material with different solids and liquid will separate off under thousands separate G force. Although screw press dewatering machine is one our new product, but it is very popular in the market, especially in south and north market. We had sold several sets different models. We will display this GNLW 101 screw press dewatering machine in 2021 WEFTEC Water Exhibition.

As we just said, screw press dewatering machine is through pressing material to dewatering. So that, it was applied to treat some soft material , such as bio-material, the fine clay of river dredging. The hard solids will damage the screw ring. As usually, we required the solids content less than 5% before feeding into this machine. And for some tiny solids smaller than 5%, we recommend to equipped chemical dosing unit to mix flocculant to help this equipment to remove out solids as much as possible.

Screw press dewatering machine has big demanded on food industry,pharmaceuticalindustry, environment industry. Compare with other dewatering machine, screw press has higher working efficient, and lower power consumer. That is a huge advantage for client to reduce their cost. As for now, GN has developed several models with the treating capacity from 100L/minutes to 30m3/hour. It can satisfied most using of different customer.

In this WEFTEC exhibition, we will display our smallest model 101 model.It will help client to understand how it work. If you have demanded on this dewatering machine, our America team will be pleased to share more information.

- Details

-

Published: 23 July 2021

Hydrovac is a very popular digging system in developed country, such as US, Canada, Australia etc. The hydrovac truck utilize high speed water to flush the ground and finish the digging. After this progress, it also suck the sludge back to the mud tank that mounded on truck. In some field that laying pipeline, optical cable, hydrovac can avoid damaging these line underground. And the most important is hydrovac will not generate any pollution in job site ,and keep the filed clean.

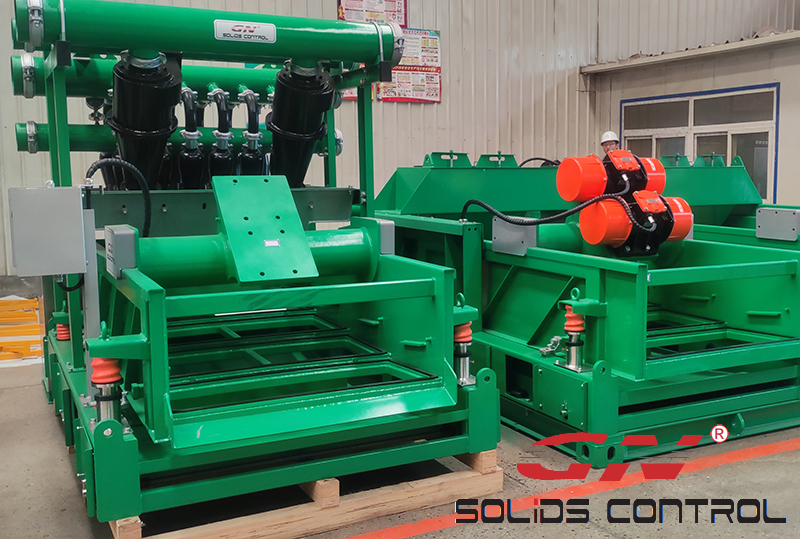

However hydrovac need to consume lots of water ,and these sucked sludge also need to be treated. GN hydrovac dewatering system is specially designed for this sludge treatment. We are first company to provide this system to hydrovac industry. Till now, we have provided more than 10 sets dewatering system to North America. Last week , we just completed one other sets system for Canada client, and ready to delivery. This system main incident scalping shaker, mud cleaner, decanter centrifuge, chemical doing unit, several pumps and mud tank.

Hydrovac truck can directly dump sludge into the mud hopper, this hopper can catch these sludge and store them, so when the truck do not need to wait for dumping to save time.The sludge will feed into scalping from mud hopper , GN used the big capacity mining shaker to make sure we can treat large quantity sludge in short time. Then discharged liquid will be feed into mud cleaner to remove out the particle bigger than 20 um. After that the liquid will mixed with flocculant to combine tiny particle into bigger and feed into decanter centrifuge. The discharged water from decanter centrifuge is clean enough for hydrovac again. The disc solids after natural air-cure, which can be used for building material.

GN has 20 truckload/ day and 40 truckload/ day , these 2 standard model system, but customize production is also workable for us. Every day, we receive many inquiry from north America, and more and more clients are interested in this system, if you also have demand, welcome to contact GN Solids America LLC, we will be pleased to share and provide technical support.

- Details

-

Published: 14 July 2021

GN solids control has been in oil gas industry for more than 3 years. We grow up from a small factory , till now GN total own 200 members, and we are building our third factory with 80,000 sq meters. GN Solids America as our branch main serve America people. As long as the company development, we also formed our own company tradition. Every year company organize the team activity, all people work together for some game challenge in the travel.

Last weekend, the whole sales department went to Yesanpo, a very famous scenic spot.We drift, barbecue, water flight, everyone enjoy it and relax. For the past 1 half year, we experienced too much, the coronavirus, the steep fall of oil, all these affected too much to all world people and also oil gas industry. In 2020, the whole year we are limited to be abroad, and the factory even can not manufacture as usually, which was useful to stop the virus spreading. But it also lead the delivery delay, everyone of our team faced big pressure. We are so thankful about the understand from client, and also their encourage.

Now everything is going back, remember the past 1 half year, which is really a tough for every GN member. However, our sale kept rising under this bad background. All these benefit from GN reputation that we got from different customers, we trust each other, and we never make our client disappoint. Stable quality, immediately after sale service. All these good job is the base of GN get a better development in the future.

Sale department is the most important part of GN. We faced customer everyday, and utilize all company resource to serve client, we also bear the biggest pressure. All of us was so relax and enjoy this travel, shard the experience each other. Which will help us get more and more tacit in work. If you are interest in GN.GN Solids Control WILL welcome everyone to join us.

- Details

-

Published: 07 July 2021