GN was funded in 2007 in Tangshan city of China.With more than 15 years development, we have become the famous brand of solids control equipment for oil gas industry in the global market, and also our equipment get the good reputation from end user. In the past 15 yeas, GN cooperated with more than 15000 customer from more than 70 countries of global. From oil gas industry to mining industry, we built strategic cooperation with many top company of the world. Many old client will purchase GN product every year many time in one year.

Last week we received new order from South America, this client is top drilling company in his countries . and this is the fifth years since first order between us. Same as before ,client will purchase one other solids control system, the accumulation is same with we provide before. OUR quality do win the trust of customer and they buy from us without stop. The system will include shale shaker ,mud cleaner , Decanter centrifuge and also centrifuge pump. They planed to purchase tank from GN also ,but considered shipping cost from China to south America ,we suggest client to make tank at their local and GN will provide design support. We design well and share drawing to client to their own built.

It is not easy to keep cooperation with client for more than 5 year. I do believe our equipment service well to client project and help them make money. This is the most important to GN to make sure our client can complete the job with GN equipment. The second important is, we also give the immediately after sale service, when client met some equipment issue, no matter what reason it is, we help client to solve problem first and then discuss the responsibility. We always consider at customer view.

GN is keeping growth, and we hope to cooperate with more client of the world. If you have demanded on solid control equipment, welcome to contact us.

- Details

-

Published: 26 June 2022

As we all know South America has high developed mining industry, such Peru, Chile, Brazil etc. Last week we shipped one set solids removal unit to Chile. This small unit is specially used for diamond core drilling slurry treatment.

When mining industry explore some area about mineral content, they need diamond drill to get geological sample to analysis. This diamond core drilling also need some slurry to cool rig to protect it and also improve the working efficiency. The wild working is not easy, worker always lack of water, so the mud repeated use and water recycling are very import to save cost , and also protect environment. However for this kind drilling slurry treating, which do not need much mud, so the slurry treatment system do not need high treatment capacity, but need to small size for transporting between different job site. GN solids removal unit satisfied all these requirement.

This mini system include GNZS752 shale shaker, 9 inch Decanter centrifuge, a small tank with mud hopper. The mud hopper is convent worker to mix some chemical to get the goods drilling slurry. When system work, drilling mud will feed into shale shaker first, this is a mini shaker with 40 cuber meter per hour treating capacity. at this stage, the particle bigger than 60 micron will be remove out. The discharge liquid will feed into GN 9 inch mini Decanter centrifuge through the bottom centrifuge pump. Under about 2500 rpm, centrifuge can easily separate off the liquid and solids, the discharged liquid can be directly used for drilling again. This small unit also can store some drilling mud for quick using in job site.

GN decanter centrifuge is getting more and more popular in mining slurry treatment. We have different model for vary treating capacity. So if you have demand, please contact us any time, we will be pleased to share our experience.

- Details

-

Published: 17 June 2022

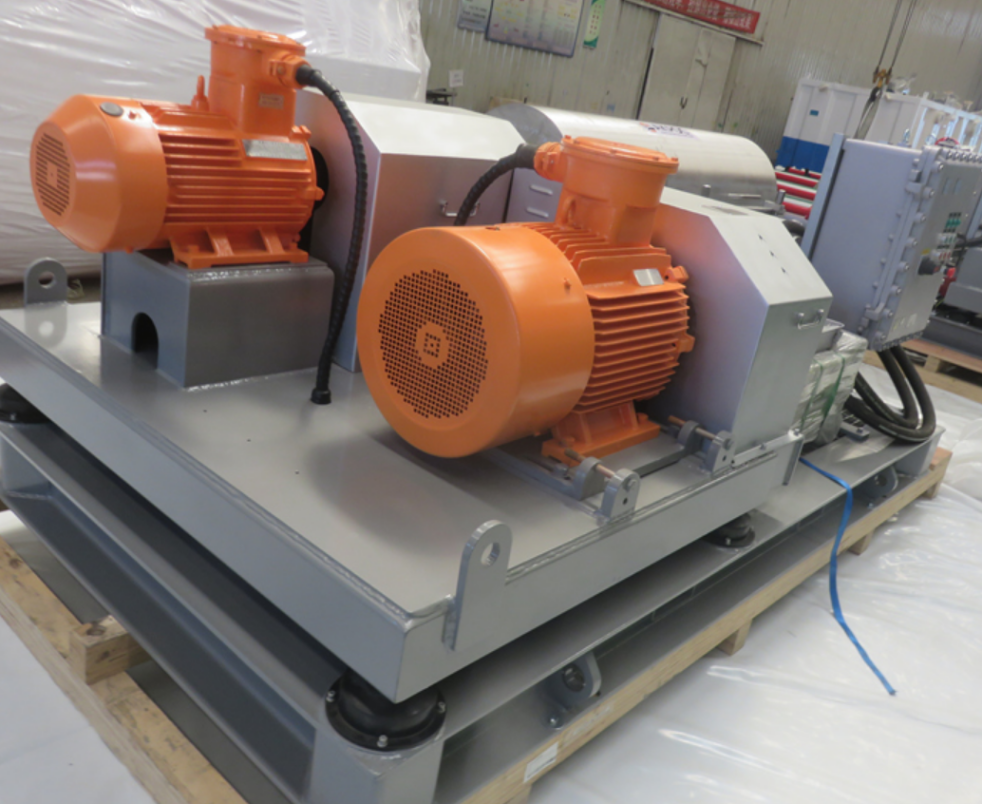

Last week we delivered 2 units GN vacuum pump to oil gas industry. This 2 units pump will be used for oil waste clean and recovery. As we all know GN has 4 models about vacuum pump based on different kind transfer capacity. They are GNSP-40B, 20B,10B, and 05B. For this order, client purchased 2 units 05B ,our mini model.

GNSP-40B is the biggest model of GN. The treating capacity is about 40 cuber meter per hour. normal used to transfer high viscosity oil sludge or some high solids content liquid. 20B and 10B are smaller model ,we sold lots to chemical industry, environment industry. Same with this 2 units model , GNSP05B also equipped wheel for user easily to move them indifferent job site. 05B is the smallest model for GN,which is only 5 cube meter per hour treating capacity. When our engineer design it ,they tried to make the pump size as small as possible. Because this pump was designed for clean dirty, especially inside of cabin and offshore drilling platform.

This order client use it to recycle oil spill, only need 1 operator to run the pump. This pump was provided different types clean suction head ,some one looks family collector, which help operator can clean all tough angle. This pump was driven by high pressure ,no electrical component. It can be used every address where high requirement to explosion proof standard. Especially the oil gas industry. The long transfer distant almost 100 meters. Client can directly transfer the waste to somewhere they want. Save lots labor and improve working efficiency.

This pump have several application, water, oil sludge,some solids powder material, crude oil etc. The strictly quality control and special structure of equipment, make this pump is very stable with long life time. It almost has no spare parts.

The pump is getting more and more popular in market, if you have demanded about them, welcome to contact us.

- Details

-

Published: 12 June 2022

In solids control system, there was one drying shale shaker , which has higher separation G force, and user to drying the discharged solids.

Dry vibrating screen or dry screen is a kind of linear vibrating screen, which is used to minimize the adsorbed liquid phase of drilling cuttings discharged from the main vibrating screen and hydrocyclone, and return the treated liquid phase to the circulating system. The drying screen shall be used in closed-circuit circulation system or in places where it is required to reduce the liquid phase content of drilling waste. There are chemical and mechanical methods to reduce the discharge of liquid phase. The chemical method adopts the dehydration reaction system and the mechanical method adopts the linear vibrating screen. The two methods can be used alone or in combination.

The dry vibrating screen can be combined with any equipment of the solid control system, such as linear vibrating screen, desander, desilter, etc. The solid phase discharged after the combined treatment of these equipment passes through a linear vibrating screen with fine mesh cloth (api200 mesh) to recover the liquid phase on the adsorbed solid phase. All the equipment is combined into a drilling fluid cleaning system, which is installed on the drilling fluid tank in a straight line with the main vibrating screen. When not used as a dry shale shaker, these equipment can also be connected to the drilling fluid circulation system to facilitate the separation of fine particles. These dry shale shakers are used to pump the treated drilling fluid from the desander and desilter, and then flow into the next stage of treatment equipment after drying.

GN drying shale shaker is one kind 4 panels shaker screen with high efficiency and stable quality. We can design and provide your solids control system with optimal way, if you have demanded on these , welcome to contact us to get more information.

- Details

-

Published: 03 June 2022

Last week we shipped 10 units shale shaker to offshore drilling platform , which is for a China drilling project. For this project, GN recommend our 5 pcs shaker screen model. As we all know, GN has vary models shale shaker, 594, 703,and 752,595. Today I will introduce this 5 panels shale shaker.

GNZS-594 is similar model GNZS-594, the difference is 594 need to install 5pcs shaker screen, so the shaker deck is longer 25% than 594 model. However ,both them used same size shaker screen, which is same size with mongoose. This is very friendly to client to get the shaker screen from GN or from their local to use their own mongoose screen. Like we just said ,5 pcs shaker own the longer deck , which mean the slurry can stay more longer time before the solids discharge, and get the longer treatment time. This is helpful to user to receive more dryer drill cutting and recycle more drilling mud. On offshore drilling platform ,dryer drilling cutting is convenient to client to transport and further treatment.

Except the longer shaker deck.GNZS594 keep using lots same technology with 594 model. The vibrator is from OLI, which is a famous brand from Italy, it is very stable. The adjust angel of shaker deck is between -1~5 degree. operator can adjust the treatment time through adjust the deck angle. Wedge system for screen fix, it is a sample mechanical method for screen install and replace, but it is stable and reliable system, this is also why GN always use this sample system.

The most of welding work was completed by robot, our labor only weld some parts where robot can not reach. Robot welding is no mistake and guaranteed the strength of shaker deck.

GN solids control have the complete production line of solids control equipment. we not only provide shale shaker but also can provide customized solids control system , if you have demanded , welcome to contact us.

- Details

-

Published: 29 May 2022