In oil gas industry, the oil sludge always the most tough thing for people to treatment. Oil sludge can not be naturally degradative and it can exist for many years with high pollution. Oil gas industry generated large oil sludge when drilling and oil storage. The oil basement drilling mud after treatment by solids control equipment, the drill cutting is one kind of oil sludge. All environment laws of different countries ruled that these kind sludge must be treated and not allowed to dump into nature environment. In other hand, oil sludge drilling mud also content drilling mud can be recycle for reuse, and as we all know drilling mud is very expensive. Whatever about the environment protection or reduce the drilling cost, the treatment of oil sludge is very necessary.

Different with drilling mud. Crude oil store always generate large sludge. Almost in all crude oil tank ,there will be settled lots of sludge on bottom. All we sure these sludge include lots valued crude oil can be recycle. For this kind oil sludge , GN developed oil sludge treatment system.

This system include chemical doing module ,thermal module, shake module, Decanter centrifuge module and also disc centrifuge module. As we all know, in low temperature, the oil is hard to separated off from solids. and we have to mixed with water to dilute the solids content, meantime wash the oil out from solids. In this case, higher temperature will be better for separation. Our thermal module can heat the sludge into 70 degree. After that we will mixed with emulsion to change the oil into some status that can be separate away with water. After that , slurry will be process be shake to remove out lot of solids, and then decanter centrifuge to remove fine solids. At last, feed into disc centrifuge to separate the water and oil away. In this system, we can get the very clean water and oil,

To different project, GN can provide several model with different treating capacity. You will be welcomed to contact us for more info.

- Details

-

Published: 23 April 2022

GN is one of the earliest China manufacturer that get into solids control industry and serve oil gas industry. With the 15 years development, GN get his reputation from user. Solids control equipment is what the best we do. GN has the whole series solids control equipment from primary separation to the end waste treatment. We can design and manufacturer the whole set solids control system. Today I will introduce the core equipment of solids control system GNLW-363 Decanter centrifuge.

As we all know shale shaker, mud cleaner both only can provide the big size particle in drilling mud. If client want to get cleaner mud, Decanter centrifuge is the best choice for further process of drilling mud. Actually the Decanter centrifuge application in drilling industry has been long history. The drilling mud after recycling time by time, the big particle can be move out by shale shaker. But with accumulation of tiny particle, the drilling mud property will be affected. Only the Decanter centrifuge can remove these tiny solids quickly. GNLW363 is specially designed for this application. Engineer considered all factors of drilling mud treatment when design this model centrifuge. Firstly, separation G Force, different with other industry requirement , the density of content particle in drilling mud is much higher than waters, so 2500 separation G force with 3500 rpm is enough for drilling mud treatment. In solids control system, the decanter centrifuge running is discontinuous, only when the tiny solids accumulate to a certain point, we run centrifuge. So 363 decanter centrifuge with 30m3 per hour treating capacity is suitable. If client required capacity is bigger, we can add one extra machine for use.

GNLW363 decanter centrifuge has fixed speed, VFD control and FHD. VFD and FHD are convenient to adjust centrifuge speed according to mud situation. And the flow rate of feeding pump is also adjusted by centrifuge box of decanter centrifuge.

We sold decanter centrifuge to more than 75 countries, if you need them, welcome to contact us.

- Details

-

Published: 09 April 2022

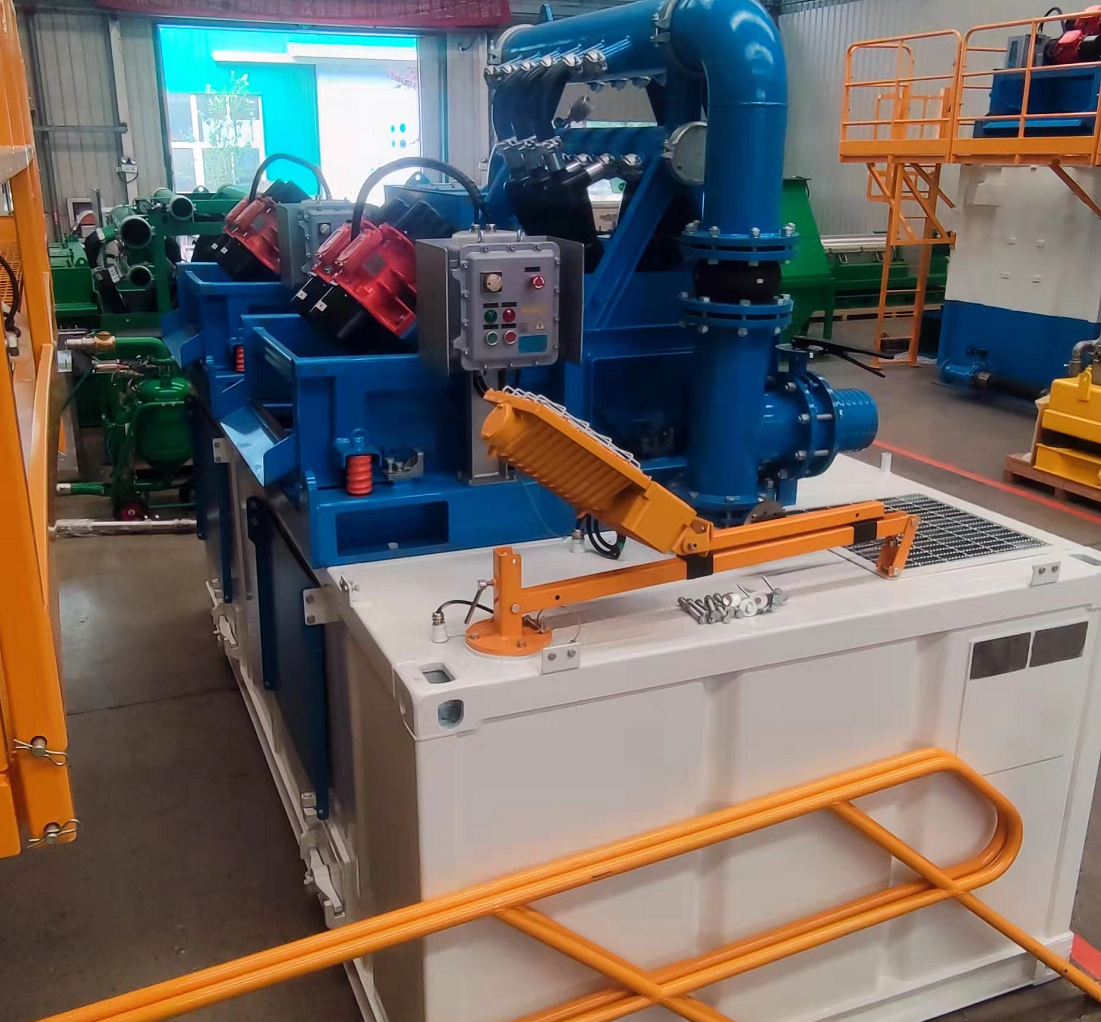

Last week we delivered 1 unit GN vacuum pump to northern America client. This pump will be applicant on the chemical industry. Vacuum pump was totally self developed by GN. And we are the only China manufacturer that can provide this vacuum pump.

The most type pump of the market are for water or some material with lower solids content. But for some high viscosity or high solids content, normal pump is useless. Many our client from oil gas industry was troubled when transfer drilling cutting, oil sludge ,or the settlement on bottom tank. Aim at these problem, GN manufactured this vacuum pump. It is different with normal type. The power is from high speed pressure air. Vacuum pump equipped a venturi device, when high pressure pump flow through venturi, the air flow will take air out from inside of pump tank, and generate a negative pressure space. Suck material inside pump tank. Higher pressure air supplied, higher suction generated. In theory, the suck distance can reach 100 meters.

This pump is automatic machine. The loading time and unloading time are controlled by a timer delay switch. Operator can setup the suction time from 5seconds to 30 seconds and also same unloading. For currently, we have 3 models according to treating capacity, 40B, 20B, and 10B. The number of model standard the treating capacity ,such as 40 B means 40 cube meter per hour. The pump standard material is carbon steel, if client have special requirement, we also can provide 304 stainless steel and 316 stainless with anti corrosive. This pump can not transfer material include chloridion. Because it will corrosive steel and damage pump.And the pump is high pressure container, any damaging is not allowed.

GN Export more than 100 units vacuum pump every year, especially mining slurry industry, this pump is very popular for slurry long distance transfer, and stable quality. If you are interested in our pump, welcome to contact us.

- Details

-

Published: 02 April 2022

In generally , offshore drilling equipment has more strict requirement to equipment quality, and manufacturer need to produce with higher grade standard. Such DNV lifting ,footprint designing, higher explosion proof standard and also the anti corrosive coating. To reach these quality standard ,manufacturer need to have full experience. GN has focused on solids control equipment for more than 15 years .We exported to more than 75 countries and provide equipment to many top oil gas industry in the global. Such as Baker Huges, Shell, Halliburton etc. GN get his reputation from the market.

Last week we delivered several set cutting drying high G shale shaker to offshore drilling platform. It different with normal shaker. This high G shaker was used to treat drilling cutting. The vibration G force can more than 8 G. Through the shaker treatment , we can recycle partial drilling mud and dryer cutting to convenient transporation. It is helpful to reduce transport cost and for the further process. As we all know drilling mud is high solution ,even the drying drilling cutting to be treatment by profession device to reduce pollution.

From the photos we can see, this high G shaker equipped a vacuum device. It connect with a liquid catch hopper installed under the shaker screen. The vacuum device can generate negative pressure. When drilling mud pass this area, the negative pressure will suck liquid out drilling cutting and dryer it. This special equipment is very popular, and it has been used in many drilling job site. Currently GN can provide two models cutting dryer shaker. One is installed 4 pcs shaker screen ,and the other is equipped 3 GN shaker screen. They have similar capacity ,which can recovery 2000L mud per day.

GN can provide a whole series solids control equipment and wast management equipment for drilling industry. We are good at customized build system according to client requirement. If your project have demanded on these equipment, welcome to contact us.

- Details

-

Published: 25 March 2022

Solids control of oil gas industry is just one branch of solids liquid separation. Although is famous with its solids control equipment in the global market, but GN also provide equipment for other industry ,such as waste water treatment from municipal project, such as slurry from HDD, TBM. The most featured product of GN is shale shaker. According to the treating capacity and different application, GN has 2 panel ,3 panels, 4 panels and double deck shale shaker.

Shale shaker is the primary separation equipment in waste water treatment. though the vibration, shale shaker can generate 7-8 G force, The solids smaller then screen opening size will go through it and down to bottom tank, certainly the water will also through the screen and be collected together with fine solids. The bigger size particle will be separated out and discharged out the shaker. Considering the treating capacity, most shale shaker consider to use the screen that mesh smaller than 270. Since the higher mesh will reduce the treating capacity, because the higher mesh meander the smaller opening size, even the water is harder to go through.

To get more clean water, we can mount hydrocyclone on shale shaker. 10 inch diameter hydrocyclone and 4 inch hydrocyclone. We call the combination unit as mud cleaner. The liquid discharged from shaker will be pumped into 4 inch hydrocyclone ,the flow under the high speed will generate separation force, the solids bigger than 40 um will be separated out. And we can get the clean water. From this photo we can see, there is also equipped a 10 inch hydrocyclone ,actually the sludge will feed into 10 inch hydrocyclone as the first step separation , and then shale shaker, finally 4 inch hydrocyclone. We designed the bottom tank as buffer to collect liquid from shaker. This is a customized design.

GN is good at provide customized solution for client special requirement. If you have demand on these separation equipment ,welcome to contact us.

- Details

-

Published: 16 March 2022