GN Solids Control Got Large Shaker Screens Order from Europe

GN Solids Control Co., Ltd is always devoted to provide the best quality products while with a reasonable price. Now GN Solids Control product series cover all solids control and drilling waste management equipments. GN Solids Control professional engineer has many new ideas every year, many creative types of equipment are also provided.

With the fast growing of GN Solids Control, GN just opened another factory which is GN No. 2 factory. GN new factory is pretty close to GN headquarters which is only 10 minutes drive. GN new factory will manufacture shaker screens and decanter centrifuges. These days, GN Solids Control is busy working on to assembling many advance CNC machines in the NO. 2 factory.

GN Solids Control can provide over 5000 pieces shaker screens every month, drilling companies from more than sixty countries and regions are using GN shaker screens. As GN Solids Control has been working with many large energy companies for many years, and they keep buying shaker screens from us, some drilling companies are purchasing over 1000 shaker screens from us every quarter.

Recently, GN Solids Control has provided over 1600 pieces shaker screens to one drilling company from Europe. GN Solids Control has many large companies keep purchasing shaker screens regularly.

Europe is one large market for GN Solids Control, with the opening of GN Solids America and GN Solids Russia, more and more companies are using GN shaker screens to replace those original screens.

GN Solids Control also manufactures various shakers. GNZS594 shaker is using the same size shaker screens as Mi-Swaco. GN also has one mini type shaker, which is most used to equip with GN mini decanter centrifuge.

This year, GN Solids America LLC will exhibit some composite shaker screens in the OTC show. Free samples can be provide to drilling companies have regular orders. Welcome to GN Houston warehouse and check GN shaker screens.

- Details

-

Published: 02 March 2016

GN Replacement Shaker Screens

GN Solids Control is a first rank manufacturer on shaker screens. Different kinds of shaker screens can be manufactured by GN Solids Control. Now GN Solids Control manufactures more than 5000 pieces shaker screens monthly. In last year, GN just established another factory, with the use of GN No.2 factory, more and more shaker screens can be manufactured.

GN Solids Control is always devoted to manufacture various shaker screens in a fast speed. The GN No.2 factory can manufacture 2 times of the shaker screens every month. GN Solids Control will be able to provide over 15000 pieces shaker screens in the near future.

The No.2 GN Solids Control company will use many advance CNC machine to manufacture composite material shaker screens. As GN Solids Control has many orders every week, large drilling companies keeps purchasing shaker screens from us, we need to produce more screens, including replacement screens for Mongoose, replacement screens for Derrick (500 series or 2000 series), replacement FSI screens as well as replacement NOV screens (King Cobra and VSM series) etc.

GN Solids Control also provides customize solutions for shaker screens are not used a lot. We only need to the wire weaving type (or a picture) and dimension. Free samples can be also provided for clients have regular orders. With the use of No. 2 manufacture plant, GN will provide more composite material replacement screens for Mongoose with a very competitive price.

Now GN has one branch company in Houston, GN Solids America LLC has a large warehouse which can stock many crates of shaker screens. For customers has large demands and urgent demands, GN Solids America can ship them from Houston, TX. Screens can also be sent to Canada and Mexico in a short period. Welcome to our Houston warehouse, we would like to show you around and give you some introduction on the GN Solids America.

- Details

-

Published: 26 February 2016

The Chinese Spring Festival is coming near, with the great effort of GN employees GN Solids Control has successfully to pass the target quota of 2015. We’d like to give our sincere thanks to all GN clients. Happy Chinese Spring Festival to you all! May the best wishes to all GN friends!

During the past year, GN Solids Control has sold many shakers, decanter centrifuges and cuttings dryers. Last year, the oil price is going down sharply from more than 100 usd/barrel to almost 30 usd/barrel, many drilling companies are suspending the drilling activities and trying to find every possible ways to cut the cost. GN drilling waste management systems are selling very well due to the excellent working performance and good quality. GN Solids Control is one of the leading manufactures in the world to provide solids control and drill cuttings management systems. With these years fast development, GN Solids Control has provided many drilling waste management systemsand modular units to global clients.

Many large drilling companies are trying so source a reliable supplier in China who can provide the most cost effective equipments, most of them will choose to GN. GN products help clients successfully cut the daily cost which is quite important as the oil price is very low. World famous companies such as Halliburton, Baker Hughes, Shell, CNPC etc are using GN solids control and drill cuttings management systems in their worksites. Last year, GN provided 4 whole sets of drilling cuttings systems to one large client in Russia, including 4 sets GN cuttings dryers and 4 sets decanter centrifuges to treat the oil base mud, now those 4 sets are using perfectly well under the -40 degree Celsius.

GN shaker screens are selling very well; they are widely used to replace Derrick, Mongoose, King Cobra, VSM 300 and some other shaker screens. Hundreds of shaker screens are stocking in Houston warehouse for quick delivery. USA drilling companies can get GN shaker screens in a short period.

- Details

-

Published: 09 February 2016

GN Solids Control is a shaker screen manufacturer, various replacement shaker screens are manufactured for world famous shakers. By using GN cost effective shaker screens, drilling companies can cut the cost largely which is pretty important especially when the economy is not good and the oil price keeps fluctuating around 30 usd/barrel.

We have already seen many large oil and gas companies are downsizing employees since the last quarter of 2015. And in this new year, we haven’t seen anything good will happen in a short period. The 2016 will be a tougher year, so using cost effective shaker screens can help cut the cost which will help drilling companies to survive.

GN manufactures replacement Derrick shaker screens for Derrick 500 series and Derrick 2000 series shakers and mud cleaners. GN500PWP and GN500PMD shaker screens can be used in Derrick 503 or Derrick 504 shaker (which is also called FLC500 series shaker). For the mud cleaner such as Derrick 513 series or Derrick 514 series, GN 500 series shaker screens can also be used.

GN replacement 500 series shaker screens including two types: flat bed type (PWP) and pyramid type (PMD or corrugated screen). All these screens are effective used to replace Derrick 500 series screens.

GN pretension shaker screen technology guarantees all GN shaker screens are performing well in the original shakers. GN replacement 500 PMD type screens has more separating room compared with the flat bed type screens, which will has better separating performance.

With these years on site feedback, GN Solids Control has been upgrading GN screens every year. Now GN shaker screens can be used for a very long period without broken. Last year, GN No.2 factory was ready to open, where shaker screens will be manufactured in that new factory. GN shaker screens can be provided in a shorter time compared to before.

GN Solids America LLC also has some other shaker screens stocking in Houston warehouse. Welcome to connect with us for your shaker screen needs.

- Details

-

Published: 29 January 2016

GN Solids Control is a leading manufacturer of shaker screens, it’s headquarter is located in China. Now GN Solids Control has two main manufacturing factories. GN Solids Control provides over 5000 pieces of various shaker screens every month. GN No. 2 factory has finished building last year, many automatic CNC machines are moving to the GN new factory. With the opening of this new factory, GN will be able to manufacture over 15000 pieces shaker screens every month.

As the oil price keeps going down, many large drilling companies are using GN shaker screens to cut cost. GN manufactures many different types of replacement shaker screens, which includes replacement Derrick 500 and Derrick 2000 series, Swaco Mongoose screens, NOV King Cobra or VSM300 series, FIS screens. All GN replacement screens are effectively used to replace those above screens with a very good separating performance while the price is very low, drilling companies can save up to 50% compare to using the original screens.

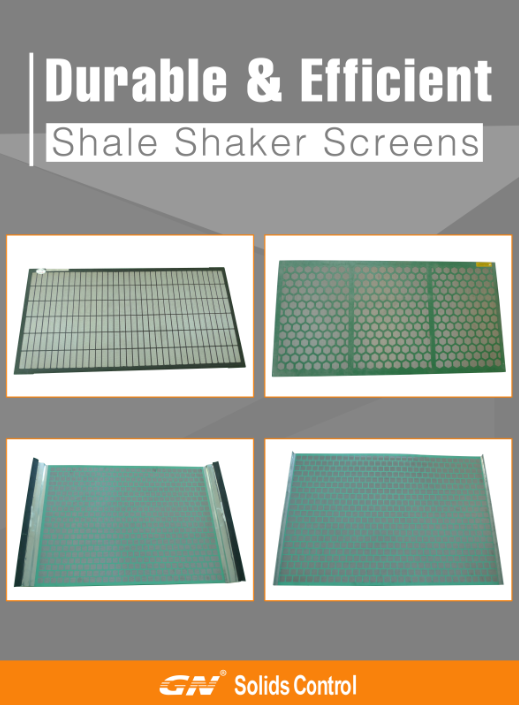

GN cutting edge CNC machines manufacture various shaker screens and keep a good consistency. GN screens include metal frame screens and composite frame screens. With the usage of GN No. 2 factory, GN Solids Control will provide more and more composite material shaker screens. The manufacturing cost of composite shaker screens are higher than metal frame screens, but their separating performance and using life is much better than the metal frame screens.

- Details

-

Published: 22 January 2016