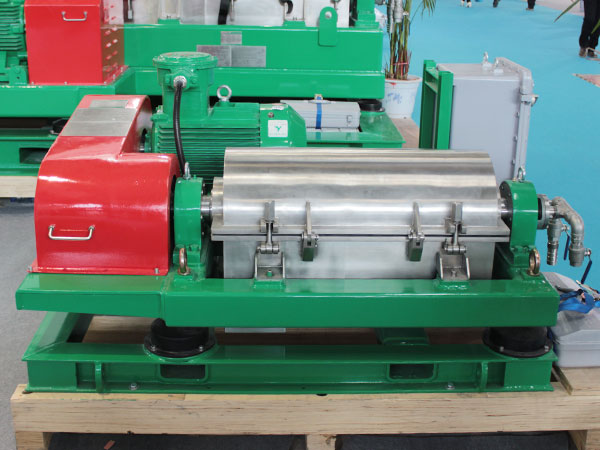

GN Solids Control manufactures different rotating bowl sizes of centrifuge, which cover the 9 inch bowl, 14inch bowl, 18 inch bowl, 22 inch bowl and 30 inch bowl. Different centrifuges are using in different area. Today we would like to give a detail introduction about GN 9 inch bowl centrifuge which we also called baby centrifuge or mini centrifuge.

GN 9 inch centrifuges are largely using in diamond drilling, core drilling, label scale slurry treating as the flow rate is around 30 gpm. Every other years, GN Solids Control upgrade its equipment in order to have a much better working performance. Now the 9 inch centrifuge GN Solids Control manufacture is the D version which comes from the original A version gradually.

GN 9 inch centrifuge bowl is also made of duplex stainless steel by centrifugal casting like the other GN bigger bowl centrifuges. There are mainly 2 models: one is fixed with single driven motor and the other model is driven by 2 separated motors.

GN 9 inch centrifuge also provides fix speed control and variable speed control to choose. Usually, if you only treat one slurry, use the fix speed is more cost effective, anyway it can also change speed by using different pulleys and belts. While the VFD is more convenient to adjust the rotating speed on the control box.

GN Solids Control is also open to provide only the centrifuge rotating assembly without motor and centrifuge foundation. Customer can choose to make it their own brand by assembling motors and paint in different colour with their own logo.

Every year, GN Solids Control manufactures and sells about 300 sets decanter centrifuges, among them 50 sets are GN 9 inch bowl centrifuges.

GN 9 inch bowl centrifuges are very popular in North America and South America, many local diamond drilling companies or mining slurry treating companies are using GN made centrifuge.

Sometimes, if there are too many large particles in the slurry, a shale shaker will be highly recommended to add in front of the centrifuge.

- Details

-

Published: 25 August 2019