After 13 years development ,GN is always consistent to provide the separating solutions for global customer .At the begin of company fund, we devote ourselves to reduce the cost for the solids-control industry by providing the high effective equipment . We do invest large capital to develop the new technology and new equipment based on the customers’ requirement. As we all know ,GN have the series equipment for different size particle separation ,shale shaker ,mud cleaner ,Decanter centrifuge ,degasser. Sometimes when the particle size smaller than 2 um with the low solids content , even the decanter centrifuge can not remove the solids from the liquid, then we need to add flocculant to mix with the material .This chemical will combine the tiny particle into big size ,and then our centrifuge can separate the solids with high efficient.

Last week we delivered 1 set chemical dosing unit to Africa customer .This unit be used for a dewatering project .After the testing in lab,our client find the adapt chemical and dosage for his slurry ,so in the actual operate ,which will need chemical dosing unit to control the dosage. This unit is a automatic machine , operator just need to set up the dosage in the control box, then will accurately feed medicine.

The unit main include medicine hopper, tank,flow control pump,water tank , control box . And for this special using situation with high temperature in Africa , our engineer equipped the air condition to ensure the unit best work performance. The flow measuring pump is diaphram pump equipment the control to adjust the flow. As we can see from the picture ,there are agitator on the tank ,this main used to mix chemical and water,after mixing the liquid will be pump into dewatering system.

This unit not only used for flocculant feeding ,but also can be used on some other chemical ,such as demulsifier . If you have demanded in this equipment , welcome to contact us , we will be pleased to share our experience and provide the technical support.

- Details

-

Published: 17 July 2020

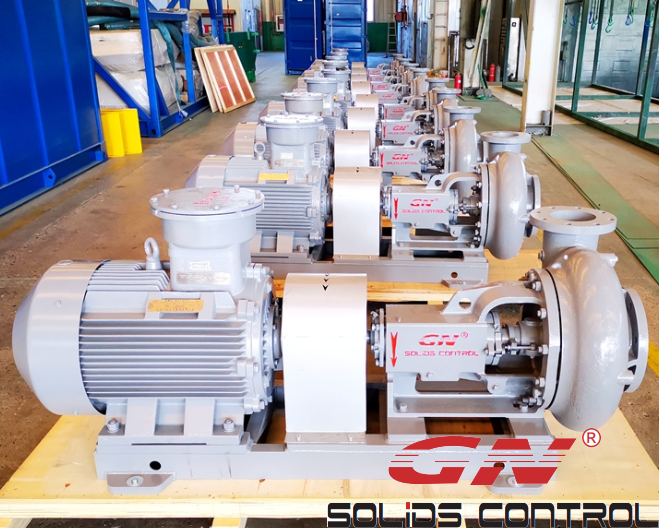

After 13 years development in the solids control industry ,GN has the built the rounded system to manufacture solids control and waste treatment equipment. As we all know these equipment is used to separate out solids from the sludge ,all these system need centrifuge pump to transfer material .Centrifuge pump is widely application in different industrious.

Centrifuge pump is one kind pump that take advantage of centrifuge force to transfer the material. It main involve the pump head and electrical motor , which is very simple structure. As usual the pump capacity can reach 320material /hour with 75kw motor , so it is a good choice for some project that require big capacity . This pump can not suck ,so the inlet need to submerge into the liquid , and pump lift between 20-35meters when pump clean water .The density of material is more bigger ,the capacity will be more smaller.

There several big and famous pump manufacturer in the world .GN centrifuge pump parts are 100% interchangeable with pump from these famous brand , quality is stable and get the good feedback from customer .The interchangeable parts means that it is easy for client to find the part supplier in their local ,which is convenient for the after sales. In the drilling mud system , the centrifuge pump can be used to feed slurry to shakers ,or combine with mud hopper to be a jet mud mixer .When feed slurry to the mud cleaner ,the pressure usually require 0.2-0.4 MPA , the small pressure will lead to bad separation performance ,so need to pay attention to the pump pressure.

GN can provide different capacity pump and parts ,the electrical motor selected the famous brand of China , table quality and good after sale service ,if you have demand in pump , please feel free to contact us .

- Details

-

Published: 12 July 2020

GN Solids Control is a famous with his solids control equipment in the petroleum market. With the 13 years development , GN equipment not only only used in the drilling mud ,but also widely used in the other industry for the solids liquid separation. As a global company ,we had built our branch in Russia and USA to serve different territory customer. We committed to provide the environment friendly equipment and solution to the different industries. Sustainable development is always our guideline to developed the new technology. Last year we are honored to took part in one waste water treatment project ,and provide 4 sets Decanter centrifuge for this waste water plan.

In the waste water treatment ,decanter centrifuge is the last step of chemical separation for the big size partical. Under the high rotated speed ,which will generated 2500-3000 G force , the small size solids will be separated with water and generated layering inside the centrifuge bowl , and then the below solids will be discharged. As usual the water plant require the big capacity centrifuge. GNSLW764 Decanter centrifuge is our biggest capacity model with 120mud /hour .The centrifuge bowl diameter is 760mm and the length is 4times of diameter ,Which is automatic and continuous. Compare with other equipment only need less worker to operate and the separation performance is more better.

Each GN decanter centrifuge must go through 3 balance testing . one is separately testing for bowl , and the assemble together for centrifugal bowl , the last is whole set machine test. We have strictly control to the material and part supplier , such as the bowl material used SS2304, the strength is more higher than other steel material .The control box choose the SMENSE or ABB, which quality is stable ,and the most important is that client will be easy to find the electrical part for replacement from these bran agent in their local .If you also have the demanded in centrifuge , please feel free to contact us.

- Details

-

Published: 05 July 2020

API is short of America petroleum Institute,which represents all segments of America’s oil and natural gas industry.For more than 90 years, API has led the development of petroleum, natural gas and petrochemical equipment and operating standards.Actually API is a common standard for the petroleum industry not only the America ,but also the whole world.

Shaker screen is one kind of consumable products in the oil well drilling process. It is installed on the shale shaker , remove out the solids from the drilling mud through the vibration. The drilling mud after treated will be reused for the drilling , the mud property directly effect the oil well drilling. So it is very important to choose the suitable screens to guarantee the drilling mud can be treated well. In the different stage of drilling will require to remove vary size solid, how we know if the screens is suitable. Someone choose the screens according to mesh (Mesh is the quantity of holes in 1 sq inch). Different manufacturing use vary diameter steel silk. Even the same mesh, if the silk diameter is more bigger, which will lead the screen hole more smaller .It is obviously that mesh is not exact parameter for choosing screen.

API RP 13 C is one kind test report of shaker screen. As usual it is issued by the third part test lab. They use the special machine to test screen to confirm which size particle can go through the screen ,and then label the screen with API No .So when customer choose the screens ,once we know the API No or the particle size ,then we can recommend the suitable shaker screens , whatever the mesh and silk diameter .

- Details

-

Published: 28 June 2020

GN has focused on the solids control inquiry for more than 13 years, now we have been the leader. For this year the third facility with 8000 sq meters will come into service.And in the new facility will use much robot to replace labor to make sure the more stable quality and improve the production capacity. Actually now 90% work is finished by robot for some products ,such as the shaker screens , the steel structure welding. GN full experience to provide equipment and service for different project ,and our equipment has the good performance in different hard working situation. Such as the desert , the north pole area and also the offshore drilling. Last week we delivered 2 units mud cleaner for the offshore drilling projects.

This mud cleaner is GNZJ594F-3S16N, which capacity is 360 m3 per hour .It is combine of GN594 shale shaker ,desander and desilter. 594F means the GN594 shaker, it is self develop equipment of GN. The 3S means it has 3 sand hydrocodones and 16N represent 16 units desilter hydrocyclones .As just told that it will be used on the offer shore drilling .So we weld the lift ring to convenient lift . And it is also the compulsorilyrequirement if the equipment used for offshore. It must comply the CCS standard .

This mud cleaner used the OLI brand vibration, it is famous brand of Italy. The shaker screen can use the mongoose screens or T585 that made by GN. To deal with different hard situation ,GN choose the special paint to anti the corrosive from the wet sea air. The control panel is meet the IEC EX or ATEX standard ,and for some electrical part we choose the SIMENSE and ABB, which quality is more reliable and it is easy to fins the replacement part from your lock SIMENSE or ABB distributor.

If you also have the project need solids control equipment , welcome to contact us , we will be pleased to provide the technical support and share our experience.

- Details

-

Published: 21 June 2020