Solids control equipment is the core business of GN, and we have committed to server drilling mud company for more than 15 years. Not only the equipment ,but also some customized system, such the mud system, drilling cutting treatment system, oil sludge treatment system etc. We accumulate large experience of the drilling mud treatment as we worked on different situation drilling project.

Last week, we just finish the produce and commissioning the drilling mud station for our South Americas client. This mud station is consist of 14 Pcs 500bbl vertical mud tank and 1 Pcs 500bbl mud mixer tank. It is a complex mud station, which can store the diesel , clean water and some solids of mud additive. One set 75kw centrifuge that can suck the mud from every tank.

As we all know the drilling mud is very important for the oil well drilling, which can protect the rig machine ,lubricate the drills ,balance the well pressure and carry out the drill cutting from the oil. The mud station is one of the most important of the drilling system to provide the high quality mud. So the mud station must be reliable. 500bbl is a big volume and the vertical tank cost is higher than the cuboid tank. Considered the transportation and also the job site area ,GN technical team choose the vertical tank even the cost is more higher. The client is urgent and require 40 days to finish all the manufacture, it seems impossible, after the discussion, the whole manufacture department support this project and we finally completed all the manufacture with high quality. From the picture you can see, every tank is huge, which required the high welding technology and machining precision , the success of this project is benefit by our full experience of some the big mud system.

Our team is excellent with the attitude that supply the best solution to save the problem for customer. If you have demanded on the solids control equipment, welcome to contact us.

- Details

-

Published: 04 October 2020

With the 15 years development, GN has got his reputation from the market because the good quality and after sale service. As we all know, at the beginning of GN found , GN main serve the petroleum industry to help drilling equipment treat the drilling mud. GN grow up quickly and gathered the full experience as we provide more and more various projects. The rich experience and the company culture that provide the best solution to client are our best treasure.

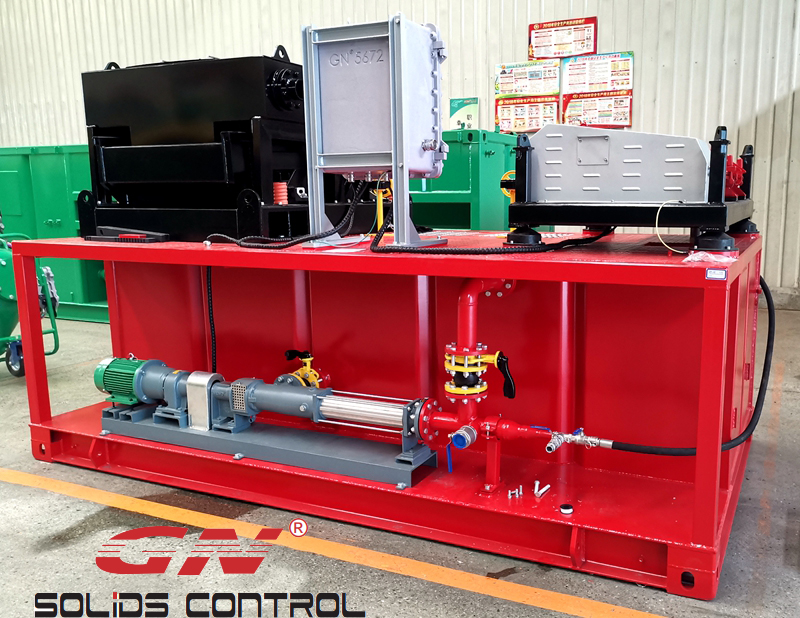

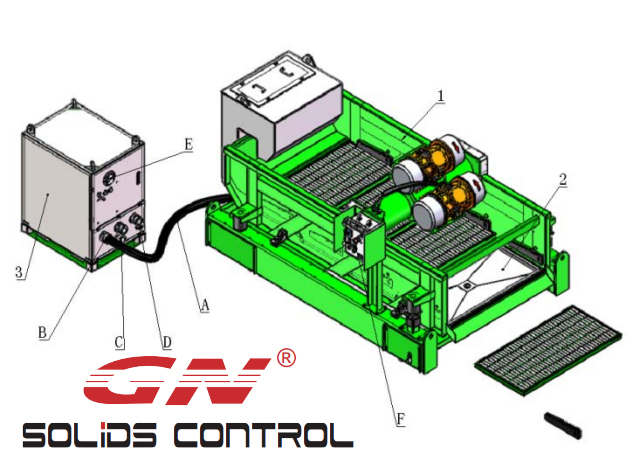

Last week we delivery Mini solids-liquid separation system fro European client. European has the most strictly require to the quality, but the client finally select us the partner.This system is a full customized , which specially designed for client project. Include the color, capacity and electrical system. This system include the GN752 shale shaker and GN223 decanter centrifuge. Both the two equipment are the smallest capacity model of GN. GN 752 shaker is a mini shaker with only 45 cubic meter treating capacity. The vibration of shaker is Italy OLI, which is a famous motor brand with reliable quality. Actually GN always choose the famous brand as the supplier. Such as the SKF bearing, SEMENSE electrical component etc. The big size solids in the material will be remove out by the shaker, and then the fluid will get into the below tank. The feeding pump will transfer the fluid into the decanter centrifuge, which can separate out the tiny solids under the high G force generated by the high rotated speed. After the system treated, we can get the clarifying liquid and dry solids. The liquid is enough to recycle into the drilling mud system for reusing.

This system is environmental friendly and economy with low power. It is continuous working system with high automatic. If you also the similar project to separate the liquid and solids, welcome to contact us. Our USA branch and China HQ both will be happy to share the experience and quote.

- Details

-

Published: 28 September 2020

GN has focused on the solids-liquid separation for more than 15 years. At the beginning of GN, we main provide the service to the oil-gas company ,mud slurry company to treat the drilling mud, and we produce the equipment for our customer, such as the decanter centrifuge,shale shaker. Most of our before equipment is used for the 2 phases separation. But for some project, which require the 3 phases separation for the oil,water,solids. With the client requirement ,we produce the 3 phase decanter centrifuge by ourselves.

The 3 phase decanter centrifuge utilized the same principle. The different density material will separate into different layers under the force that generated by the high rotated speed. The solids will be on the bottom layer, the water stay on the middle layer, and the water in on the top layer. Solids and water are same way to discharge, but the oil will be pumped by a centripetalpump. According to the capacity ,GN Decanter centrifuge have 5m3,10m3 and 15m3 the 3 different models. The biggest rotated speed can reach 300 RPM can generate 3060G force. All different model are driven by VFD, the rotated speed is adjustable.

GN decanter centrifuge has lots of feature. As we all know the screw sclloper is very easy to wear under the touching with material with the high rotated speed. GN select tungsten carbon tile to bolt on the screw for the long life time ,even the tile is consumed, it is very easy to take down and you just to replace the broken part ,because it bolted installing. The rotated bowl are passed 3 times for the balanced test to make sure the perfect work performance. And also the material choose the SS306 for more longer life time.

GN 3 phase decanter centrifuge can be used on many different industries, the oil sludge treatment ,the kitchen waste treatment, the chemical material extraction etc. If your project have the demand on the 3 phase separation, welcome to contact us , we will be pleased to share our experience and provide the equipment for your project.

- Details

-

Published: 20 September 2020

GN was found in 2005, with the 15 years development, GN was famous in his solids control equipment. And we also develop some equipment with new technology and used to improve the efficiency of drilling. In the oil well drilling and some other project such as the HDD,tunnel boring,pipe jack. The drilling mud is very expensive and also high polluted. So we always try to recovery the drilling mud as much as possible.In the drilling treatment ,the shale shaker is the most important and widely used to treat the slurry, but the normal shaker only can roughly separate, the discharged solids still include lot of drilling mud ,which is a waste, and also improve the cost of drilling slurry.

GN VIST is one kind auxiliaryequipment of shale shaker, which main used to increase the shaker working performance to dryer the solids and recover more drilling mud. VIST is driven by air ,so it can be used in every area even request the high explosion proof level. As we just said VIST utilize the air pressure to suck the liquid that included in the solids and recover it. There will be a catch pan installed under the screens,when start the VIST unit ,the space between screens and catch pan will generate the negative pressure. When the material flow on the screen ,the negative pressure can suck the liquid through the screen and be collected by the catch pan.

According to our test and using report from our customer ,the shaker equipped with VIST , which can recover more 30%-40% slurry, and the solids is also more dryer. The VIST can fit under most shaker models in the market , and one unit can match with 3 sets shale shaker. It need 4.5m3/min air supply with 0.7-1.0 Mpa pressure. The pressure and air flow can be adjusted according to actual situation.

VIST is a high efficient equipment to reduce the waste of slurry , if you want to know more ,welcome to contact us. We will be pleased to share more the information.

- Details

-

Published: 10 September 2020

After 15 years development ,GN not only serve the oil well drilling ,but also provide equipment to the waste water plant. Actually the drilling mud and waste water treatment both are remove the big size solids and recycle the liquid. GN P series decanter centrifuge is specially used for the wast water treatment. Last week we delivered the GN 554 Decanter centrifuge to UK, and also the screw conveyor for the solids conveying.

GN 554 Decanter centrifuge is the second large capacity equipment, which has served many project of all the word ,oil well drilling mud treatment , waste water treatment ,and also in some chemical industry. 554 Decanter centrifuge is driven by VFD, the max rotated speed can be 3150 RPM , and max G force is 3051G. The bowl diameter is 22 inch and the length is 91 inch. The longer bowl can keep the material staying more time is the screw bowl , then the solids-liquid can be separated more better .GN used many special material to the centrifuge, such as the bowl is whole body cast with SS316 steel, it is more stronger. The screw used the anti wear material Tungsten Carbide Tiles, which makes the screw work for more longer life, and the tiles are installed by bolt ,it is very convenient to repair and replace. Some our competitor weld the anti wear material on the screw, so it have repair the whole set screw ,even part of the screw was damaged.

As the request customer , we produced the screw conveyor for customer’s project. This conveyor is combine with sever sections, each section is same diameter and they can connect together into a more longer conveyor. Which is really good idea for the shipping. Because it will hard to transport if the conveyor length is longer than container.

GN has the rich experience in the solids -liquid separation project , if your have the similar demanded, we will be pleased to share our experience and provide the technical support.

- Details

-

Published: 06 September 2020