As we all know, GN is famous with the solids control equipment, and we have served the oil gas industry for more than 15 years. Our equipment is very popular in different country because the excellent quality and quickly after sale service. Solids control equipment is main used to treat the drilling slurry, not only the oil well drilling ,but in some HDD project, tunnel boring project also will use drilling slurry. We are also full experience to treat these drilling mud. Last week we provide the big centrifuge bowl decanter centrifuge for tunnel boring project.

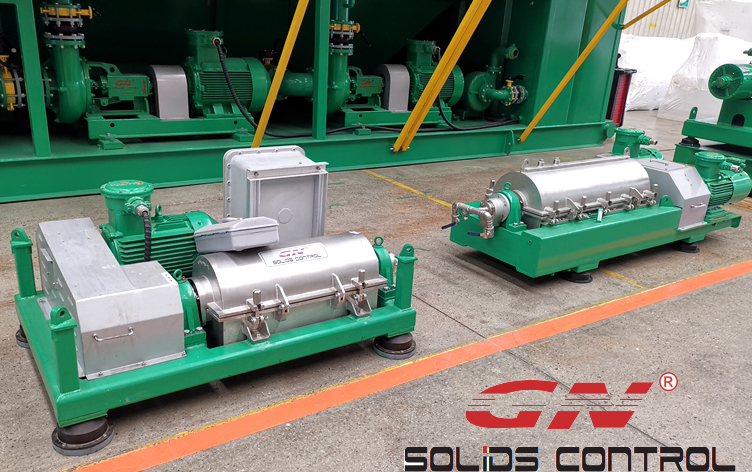

Tunnel boring machine is widely used for the subway project and mountain tunnel. When it work,the machine need to large mud to cool the rig and the mud will carry the drilling cutting out the tunnel. The normal small decanter is not enough to separate so large drilling mud. It must used the big capacity. GN 764 decanter centrifuge is the biggest model of GN, which centrifuge bowl is 30 inch, and the capacity is 120m3/hour. It is a good choice for these big project.

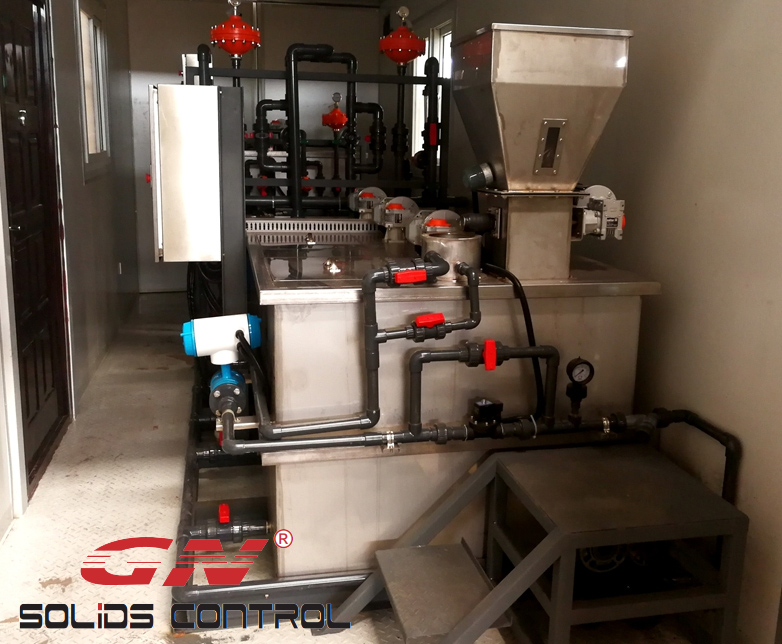

In this project, client require that the recycled water must be very clear to reduce the water consume. And also the discharged will be convenient to transport and further treatment after dewatering. To reach this target, we add combine chemical dosing in this system to add flocculant, which can combine the tiny solids into big, which will be helpful to decanter to separate out the solids. Form the photo you can the discharged water is very clean and can be directly reuse.

In the modern project, we have to reduce the consume of water source, protect the surrounding environment. Decanter centrifuge is good choice for the waste management. GN not only provide the decanter centrifuge ,but also the whole solution for various project. Such as the solids control system for well drilling, mud system for HDD, Mining slurry treatment. You will be welcomed to contact us for more information.

- Details

-

Published: 10 November 2020

As we all know GN has two main business, one is solids control and the other is waste treatment. Both are need the separation equipment to remove out the solids from material, and recycle the water or oil as much as we can. There are so many different kind sludge, so sometimes we need to choose some chemical medicine to mix with slurry to get the best separating effect. There are 3 kinds most common chemical medicine, they are surfactant, flocculant and demulsifier.

With the different separation target, we should choose different combination of medicine. If the decanter centrifuge only include the water and solids, and the solids particle size bigger than 5um, sometime we do not need to add chemical ,because the solids content will less than 3% after treatment by decanter. Or we can raise the rotate speed of decanter to improve the G force to get the more better separation performance. But when the particle size smaller than 5um, we need to add into flocculant to combine tiny solids into big particle to help the centrifuge separate well.

For some high solids content material with oil water. As usual, this kind material is low liquidity, the oil and solids also combine together. We need to add the surfactant first and clean water to attenuation. After that we could treat the slurry by shale shaker to remove most solids and get the liquid. Then we need to add demulsifier ,which can strip the oil from solids liquid, and this reaction is finished in the material. After that feed the liquid into decanter centrifuge. Our decanter can separate out 95% solids. The liquid discharge from centrifuge, which main include water,oil and solid (less than 5%). In the end, we need to add the flocculant to combine the tiny solids into big ,this will help the disc centrifuge to remove out almost all solids. After disc centrifuge treatment, we can get the 3 phases separation,oil ,water and less solids.

For some complex material, testing in advance is always necessary, if your have the separation project ,welcome to contact us, we will be pleased to share our experience.

- Details

-

Published: 03 November 2020

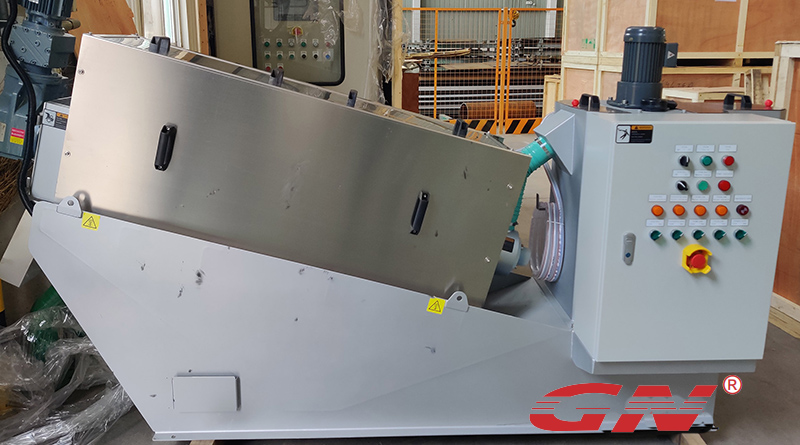

GN has focused on on separation industry for more than 15 years. At beginning, we main served the oil gas industry to help our client treating the drilling mud, such as the shale shaker, mud cleaner, decanter centrifuge. With the company development and the technology accumulation, we have developed many different kinds separation machine for different application. Such as the screw press dewatering machine. Last week we delivered our 201 models screw press to our customer from Peru.

Screw press dewatering machine is different decanter centrifuge. Decanter centrifuge utilizes the centrifuge force that generated under the high rotate speed, the solids and liquid will be separated into different layers. Screw press is through press material to make the solids dryer and get the clean liquid, the energy consumption is more lower. As usual, it can not treat the material with hard solids inside. And also need to mix with chemical to combine the solids into flocccule and then the machine can separate well. The treatment capacity is depended on the solids content of material. The more higher solids content ,the smaller treatment capacity. As usually, the max solids content should no more than 5%, otherwise the material should be treated by shale shaker to reduce solids content.

Low power consumption is the the biggest advantage compared with other equipment. For example the biggest model GNDL-404 with 52m3/hour capacity, which power is only 6 kw, the same capacity decanter centrifuge is 37-45kw. This feature makes it very popular in different industry, especially in the food industry, waste water treatment etc. And also for some special industry, we can use different material to satisfied the industry standard. For example ,we choose stainless SS316 for food industry.

GN has lot of experience in solids-liquid separation,not only the equipment, but also some customized system for special project, we provide the technical support by free. If your project have demand in our equipment, welcome to contact us.

- Details

-

Published: 27 October 2020

With the human development, the human activity really affect a lot to environment, and lead to the big pollution to ecosystem. And we also customer a big large of resource and generate waste. GN has committed on the waste treatment for many years. We are happy for our work to provide equipment to treat waste and make it to reuse again. For most waste material, the first step of treating is separation. We need to sort out the waste into different types. Such as the sludge, which include solids and water, GN decanter centrifuge is good optional for these kind sludge treatment. Last week, we delivered the Vacuum pump and decanter centrifuge for environmental project to treat the sludge.

These waste from the water tank in water plant. The bottom of water tank will deposit the solids, it is will block pipe and dirty the water. Client choose GN 224 decanter centrifuge to treat this sludge. As normal, the decanter centrifuge is good performance to treat the material that solids content less than 20%, and after treating solids content will no more than 5%. GN224 decanter centrifuge is the smallest capacity decanter with 100 liter/min. It cover a small area and convenient to transfer in different project, and actually the bowl diameter is only 220mm and 890mm length. The waste discharged from the decanter is clean enough to reuse, and the solids will be transport away by solids vacuum pump. In this project, we provide 5m3/hour solids vacuum pump , it is suitable to match with 224 decanter. The vacuum pump is drive by air, and you can see it is also small and equipped with wheel. The vacuum pump transfer distance can reach 500 meters. It can reach most requirement of project.

GN has strict quality control and full experience for the separation project, and we have branch in Houston ,If your project have need in these project , welcome to contact us.

- Details

-

Published: 20 October 2020

GN committed to manufacture the most reliable quality with quick after sale service. We had focus on the solids-liquid separation industry for more than 15 years. At the beginning of GN, we main serve the drilling company to treat the drilling mud. We never stopped to develop the new technology and update our equipment .Today I would like to share GN 223 Decanter centrifuge.

The decanter centrifuge is widely application in different industry. GN has the various model decanter with the different treating capacity. According to the bowl diameter, we have 220mm bowl decanter,350mm, 450mm,550mm, and 760mm. The more bigger bowl diameter require more higher process technology. Big diameter bowl centrifuge most used on some the high treating capacity project. Less company provide the small capacity decanter, actually many client require the mini centrifuge for some testing project.

GN 223 decanter centrifuge is the smallest decanter centrifuge with 220 mm diameter bowl, which bowl length is 3 times of diameter. It is small electric consume ,and the treating capacity is 100L/min. The max speed is 4500rpm with 2492 G force. It is very suitable for the separation of mining explore material. Little quantity and easy to transport to different job site. The centrifuge bowl material is SS304, which is more strength and anti-wear. And centrifuge bowl assembly main include the bowl ,screw, gearbox, belt pulley and tensioning wheel . It is simple structure with high assembly precision. And also centrifuge assembly is the most important part of decanter.

Our decanter have two types of drive, one is fixed speed and the VFD. VFD is higher cost and but it more widely application, because we can adjust the rotated speed according to our requirement. Foe now ,GN223 decanter centrifuge has exported more than 60 countries and get the good feedback from out customer. If you have demanded on the decanter centrifuge ,please feel free to let us know.

- Details

-

Published: 11 October 2020