IE Expo China is big exhibition that hold in August in Shanghai China. GN as leader of solids control and waste treatment industry, also attend this exhibition as an exporter. For the past years’ exhibition, there would be many buyer from all over the world in different industries,such as the petroleum, waste water, drilling ,chemical etc. But for this exhibition ,there is less foreign buyer attend due to the COVID-19. Most are the representative purchase and searching equipment for the abroad importer. However we still built good connection with many buyers.

For this exhibition ,GN bring the oil sludge treatment system and decanter centrifuge .This two equipment are very popular in many countries for the past several years.Especially the oil sludge treatment system ,which is main used to separate out the solids,recovery the oil and water from the oil sludge. At begin ,it most used in the oil well field to treat the oil base drilling mud.As we upgrade this system,which is more widely using now, such as the industry waste oil ,waste lube oil and also the biological wast oil. It is truly recovery ,recycling and environment friendly.

We also take the decanter centrifuge to exhibition.As we all know decanter centrifuge is always one feature product of GN. After the several years development ,we have EY,EP,EC these 3 different series of Decanter. EY used to separate the solids and liquid ;EC apply to clarify the liquid ,and EP is dryer the solids .Good price with stable quality ,this is the advantage of us.The exhibited Decanter centrifuge attracted a lot of attention ,because to different industry application, the corresponding model is more specific to get the best effect.

It is exciting to meet so many client on exhibition ,and shared the experience each other. We sincerely invite you to visit us to know more about us.

- Details

-

Published: 21 August 2020

GN is a equipment manufacture of solids control and waste treatment .At the begin of GN history , we main provide the equipment and service to the oil well drilling company ,such as the shale shaker ,mud cleaner ,shaker screens and also mud system etc .These equipment is main used to treat the drilling mud ,remove the solids from the mud. As long as the development of GN ,we not only serve oil well drilling , but also the other industrious which has the demand of solids-liquid separation. Last week we delivered one drilling mud solids control system for coal mining.

This solids control system has two application. One is clarify the drilling mud that generated in the coal drilling. This system include 2 units GN shale shaker, 1 set GN desander, 1 set GN desilter and also the centrifuge pump. The two sets shale shaker can remove the big particle size that bigger than 60 um. And the pump will transfer the material and feed into the desander . The desander is combination of hydrocycloe and shale shaker. After the desander treatment , will treated by the desilter ,desilter is used to remove more smaller particle. The drilling mud will be clean enough for reuse.

Except the solids control equipment ,this system also equipped the mud jet mixer. In the drilling program ,sometimes we need to adjust the mud density ,that need to mix some special material with water. This mud jet mixer include the mud hopper and centrifuge pump. This is a high efficiency unit with 45-340 m3/hour. This mud system consider the shipping delivery when make the design ,so the mud tank dimension can be load into container to transfer.

GN can provide the customized proposal for your project. That is our advantage to serve customer ,because different project has the different requirement. If your project has the demand to the solids-liquid separation , welcome to contact us , we will be pleased to share our experience and provide the technical support.

- Details

-

Published: 17 August 2020

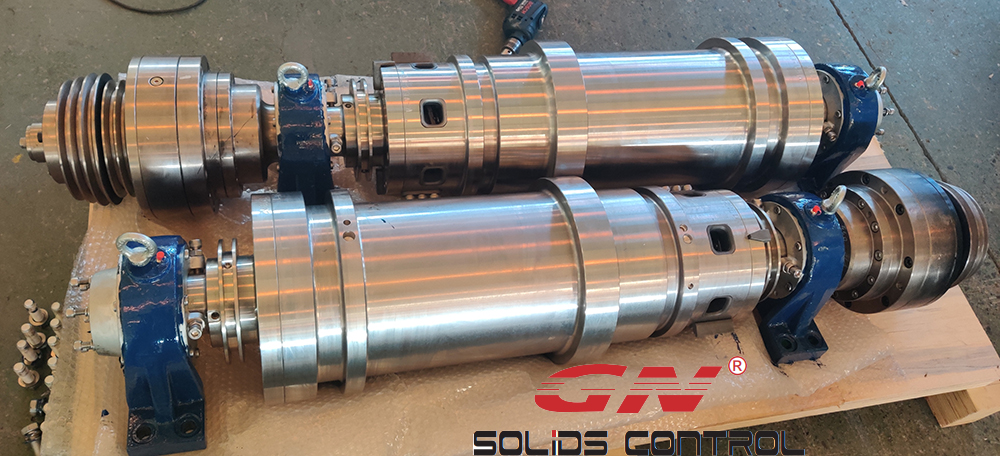

As we all know the decanter centrifuge is one of the most popular equipment of GN. I would like to share the feature of GN decanter centrifuge.

First , decanter centrifuge is one kind machine that easy to wear . we select duplex stainless steel SS2304 and centrifugal casting are used to manufacturing rotating bowl, and shaft for big and small end cap. Duplex stainless steel is stronger and more resistant to abrasion and corrosion. This manufacturing process also avoid intergranular corrosion and incomplete release of stress. Screw blades are manufactured as a whole piece with CNC forming lathe, leading to high accuracy of the blades and higher solids discharge efficiency.

Second,optimized cone and pitch with BD plate to separate dewatering section and settling section, with deeper pond depth, longer dewatering section, dryer solids and clearer water. This also increase throughput speed. BD plate also helps solids discharge.

Third ,Less energy consumption is achieved with bigger pond depth, making decanter centrifuge use less energy. This also reduces turbidity flow of liquid to make separated water clearer, less wear on end blades which makes screw lastlonger.Dual cone angle is available for specific high solid concentration materials. The rotating bowl have two cone angles, which reduced discharge resistance and increase treatment capability while maintaining clarify of water and dryness of solids.

Third, All the rotating parts are made with high accuracy CNC machine. After that 3 step dynamic balancing is done. One is the balancing of rotating assembly at 1800RPM, balancing at real high speed and the balancing of whole machine to ensure stable operation of the decanter centrifuge at high speed.

Fourth,Part of centrifuge select the protected tiles and special design for easily operate and long lifetime .Discharge ports are specially made tungsten carbide with excellent anti-abrasion capability and less fragility;Easy opening mechanism is used so that one man can open the collection box cover for easy access of equipment; Hydraulic removing mechanism is built into main shaft, which reduced pulling force by 90% when removing main bearings, this helps to ensure the safety of the bearing and high precision parts; Both motors are placed in one end of the decanter centrifuges for more service space and spill of slurry to impact service life of motors;Oil lubrication is used to lower bearing temperature and clean bearings;

Fifth, select SKF premium bearing is used for longer service life, and the Real time monitoring of decanter centrifuge’s working condition for overload, bearing temperature, vibration, lubrication pressure, drive currents and screw torque and alarm .

All these feature make GN decanter centrifuge is one kind stable and reliable equipment ,If you want to know more , welcome to contact us.

- Details

-

Published: 05 August 2020

After 13 years development GN has been the leader of solids control equipment. We had built three plant with more than 800000 square meters to manufacture different solids control and waste treatment equipment .Most GN equipment is used for drilling mud treatment to remove its solids and clarify the mud again for reuse . Actually GN equipment not only an be used for the oil gas industry ,but also good performance at some environment projects. Such as the waste water treatment. Last week we delivered vertical cutting dryer and screw conveyor to our customer .

The vertical cutting dryer is not used to treat the drilling cutting , which is used to dryer the solids phase that separated from shale shaker in the waste water treatment project. As usual , the solids discharged from shale shaker is very wet, it is inconvenient to transport, so we need to dryer it .GN vertical cutting dryer is big capacity machine with 50 tons /hour. And it is continuous work .After treatment the liquid content is only 8%-20% according to the different situation .It is a stable equipment ,the inside screen is processed with the special technology and anti -wear material. That can ensure the long lifetime . from the picture you can see that it install in a container ,that is because this project is a very cold area and it is also convenient for transport.

Except the cutting dryer , we also equipped the screw conveyor to feed material to cutting dryer ,solids will directly convey from shale shaker. This will help to improve the efficiency and reduce the cost of labor . The screw conveyor can increase the length according to the actual requirement , you just need to add the module section ,each section is 12 feet. Big capacity and stable.

GN has full experience in the solids-liquid separation ,not only in the oil gas industry ,but also environment project , if your project have demanded in these equipment , please contact us.

- Details

-

Published: 02 August 2020

GN is a leader of solids control equipment in China .We have focused on providing the equipment and service to energy company for more than 13 years history. Except GN HQ in China , we built two branch company in Russia and USA, the two branch company can quickly provide the after sale service for local client. And in USA branch, we built our warehouse in Houston for rapidly response to customer purchase.Last week we delivered the vertical cutting dryer to Russia.

GN vertical cutting dryer is completely independent research and development ,this cutting dryer after several upgrade,which can win the mote difficult working situation and get the good feedback from customer. Not only the cutting dryer ,but also all GN equipment comply with API quality management, especially the shaker screens passed the strictly test by the third part and got the API RP13C report .

GN vertical cutting have fixed speed and VFD two model. For this customer ,we delivered the fixed speed model. The rotating speed is not adjustable. As we all know the Russia is very cold ,this is a challenge for every equipment and also operator .We put the cutting dryer into the container house to keep warm and make sure the best work performance.This vertical cutting dryer most times used for oil base mud .The drilling mud after shale shaker treatment ,the discharged solids steel is still contain large liquid. These solids can directly feed into cutting dryer, after treatment the OOC will less than 5%, which is very dry and convenient to transport and reduce the pollution .Most important is that the mud discharged by cutting can be used again for drilling .The capacity is 30-50tons based on the actual situation .High efficient,stable,environment friendly ,If you have demand in these equipment ,we will be pleased to provide the technical support and share our experience.

- Details

-

Published: 26 July 2020