GN Solids Control has been manufacturing shaker screens for many years. Now GN Houston branch company which is GN Solids America LLC has thousands of shake screens in stock.

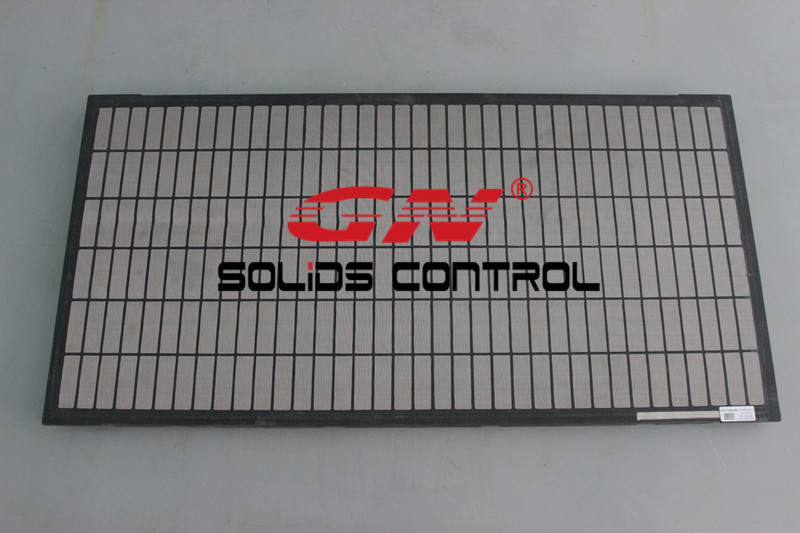

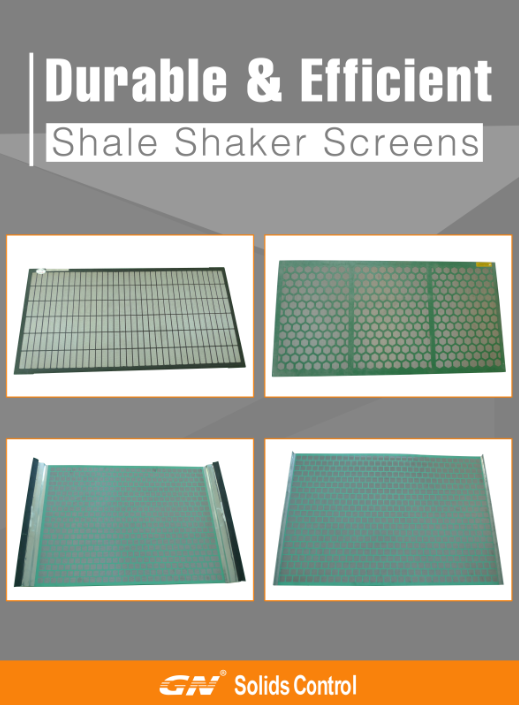

GN Shaker screens are widely used in hundreds of drilling rig sites. As we all know, shaker screens are wearable parts, they all need to be changed after used for some days in order to have a clear drilling mud. GN made shaker screens can be used on most those largely used shakers, such as NOV shaker, Mi-Swaco shaker and Derrick Shaker etc. Before GN Solids Control manufactured hundreds of metal frame shaker screens, but with the new technology usage, more and more customers prefer to use composite frame shaker screens. GN made composite frame shaker screens are tested to last longer than traditional metal frames, which are also provided during parallel testing.

GN Solids Control is always devoted to provide the most cost-effective shaker screens to global customers. Even in US, many customers keep using GN shaker screens.

So why GN made composite frame shaker screens are better than those metal frame ones?

1.GN composite frames screens are using new technology. Inside they are still metal frames which are welded by automatic robot welding, and the screen frame are sent to Inject Moulding machine to cover a layer of high quality plastic.

2.By using the same screen cloth manufacturer with Derrick and Mi-Swaco, GN Solids Control keeps the screen quality at high standard.

3.Most shaker screens manufacturers are using 3 layers screen cloth when API no. Larger than API 120, while GN Solids Control use 3 layers start from API 60. From this point, GN shaker screens can also long longer.

4.GN Solids Control is the first the only one that can pass the third party test report.

Call our Houston office 713-878-0880 for your screen needs.

- Details

-

Published: 25 May 2019