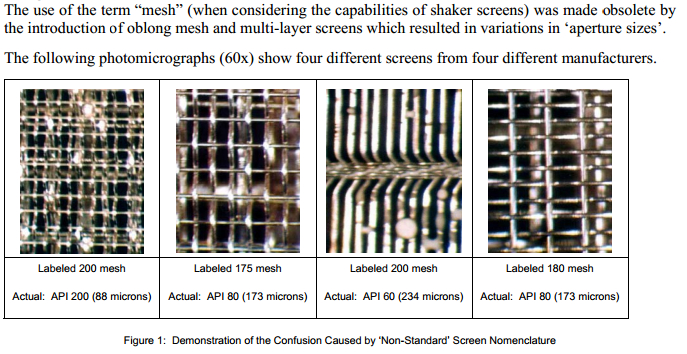

Before we get a standard API RP13E, screen suppliers use oblong mesh to define the shaker screens, though it is kind of old fashion, but it is still very useful lets see, eg. for Brandt 4x5 shaker, approximately 48-1/4" OCW x 59-1/2", it is still efficient to use B-40 Screen Single Layer (20 x 30 Mesh) (Oblong) 40 to make both user and supplier understand each other.

Oblong is an older brother comparing XR XL and all other rectangular or square holes technology.

Oblong is an older brother comparing XR XL and all other rectangular or square holes technology.

XR Mesh is utilized in a unique three-layer arrangement that creates exceptional shale shaker screens. The XR screen design features innovative oblong openings with a greater length-to-width ratio than other rectangular meshes.

It also incorporates wire diameters that are 50 percent larger than comparable meshes.

The large diameter wire is calendared to lock mesh openings securely in place. All three layers are made of finely woven stainless steel. The middle layer increases screen life by acting as a buffer between the fine top mesh and coarse backup layer, as well as serving as a mechanical deblinding agent for the top mesh.

To extend the screen life, bare more capacity, being comply with the API standard, every supplier is developing their own way to make the screens better, that is why we have DX DF HP and so on.

Different screen construction also make the world more attractive.

- Details

-

Published: 09 May 2014

-

Created: 09 May 2014